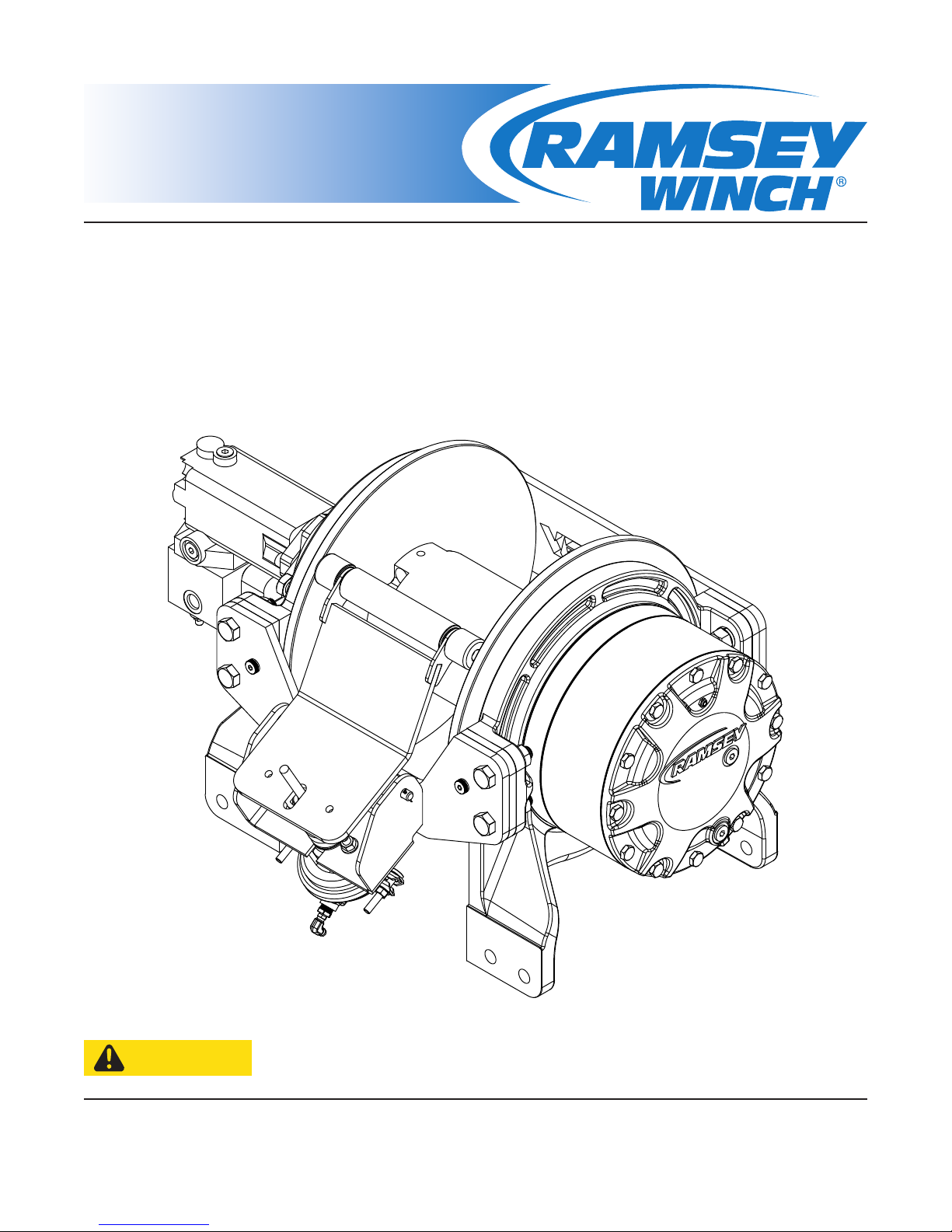

HERCULES 50K 5

Winch Operation 3

The best way to get acquainted with how your winch operates is to make test runs before you use

it. Plan your test in advance. Remember, you hear your winch, as well as see it operate. Learn to

recognizethesoundsofalightsteadypull,aheavypull,andsoundscausedbyloadjerkingor

shifting.Gaincondenceinoperatingyourwinchanditsusewillbecomesecondnaturewithyou.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pileup

on one end of drum. If this happens, reverse the winch to relieve the load and move your anchor

pointfurthertothecenterofthevehicle.Afterthejobisdoneyoucanunspoolandrewindfora

neat lay of the cable.

CLUTCH OPERATION

To engage clutch:

1. Move the clutch control valve to the “clutch engaged” position.

2.Anytimethetemperatureisbelowfreezing,runthemotorinthe“cableout”directiononlyuntil

the drum starts to turn. In extreme cold temperatures (below 0° F/-18° C), pull out on the cable

by hand only until the drum starts to turn.

3. Wait at least 3 seconds for the clutch to fully engage, after which the winch is ready to winch in

the cable.

Donotattempttoengagetheclutchbyrstrunningthewinchmotorand

then moving the clutch control valve to the “clutch-engaged” position while

the motor is running. Do not start picking up the load at the same time the

clutch is being engaged.

To disengage clutch: Run the winch in the “cable out” direction until the load is off the cable.

4. Move the clutch control valve to the “clutch-disengaged” position.

5. The cable may now be pulled off by hand.

CABLE INSTALLATION

1. This winch has a cable anchor located at each end of the drum which

allows cable installation on either end.

2. Unwind cable by rolling it out along the ground to prevent kinking.

Securely wrap end of wire rope opposite hook, with plastic or similar

tape to prevent fraying.

3. Insert the end of cable, opposite hook end, into the hole in drum

barrel. Secure cable to drum barrel, using setscrew furnished with

winch. TIGHTEN SETSCREW SECURELY.

4. Carefully run the winch in the “reel-in” direction. Keeping tension on

end of cable, spool all the cable onto the cable drum, taking care to

form neatly wrapped layers.

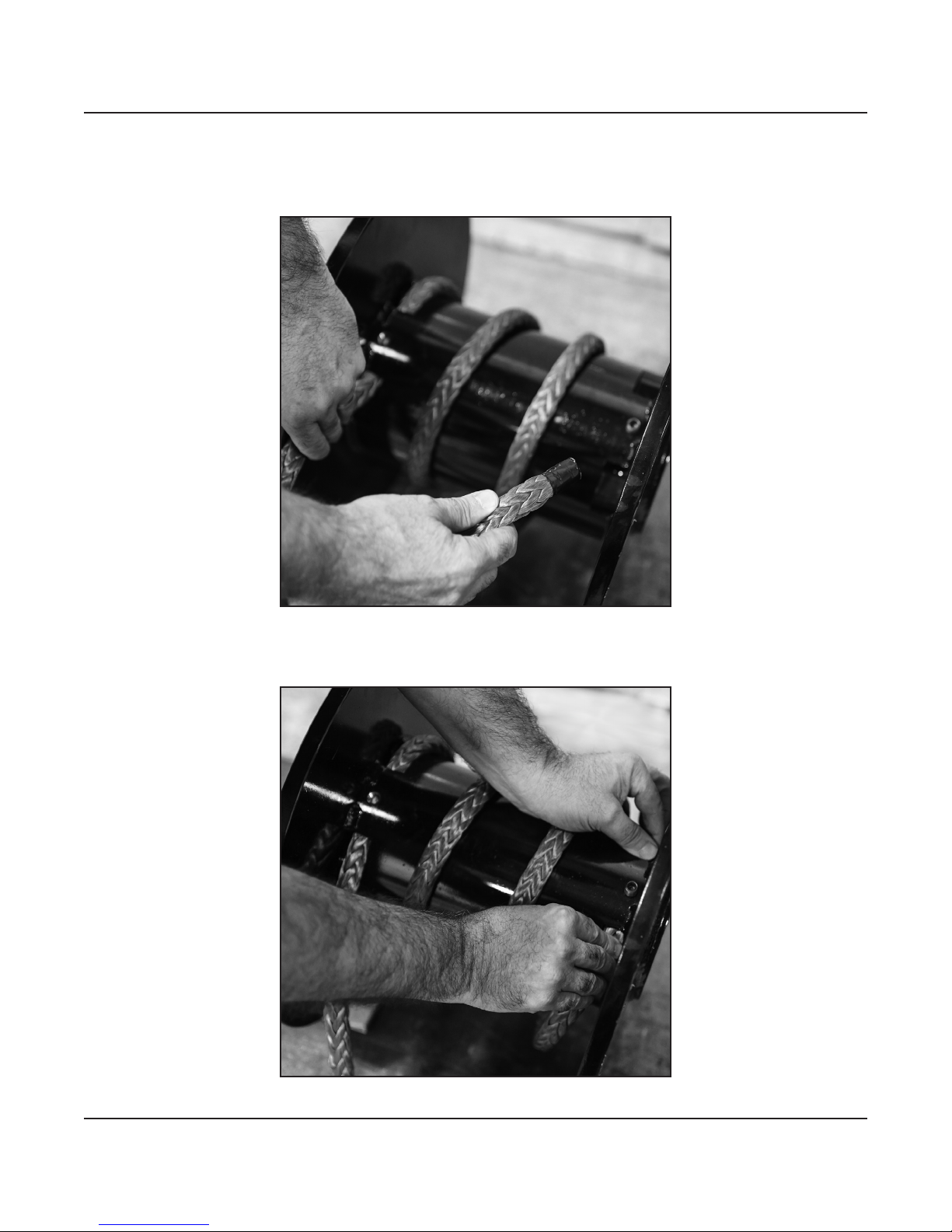

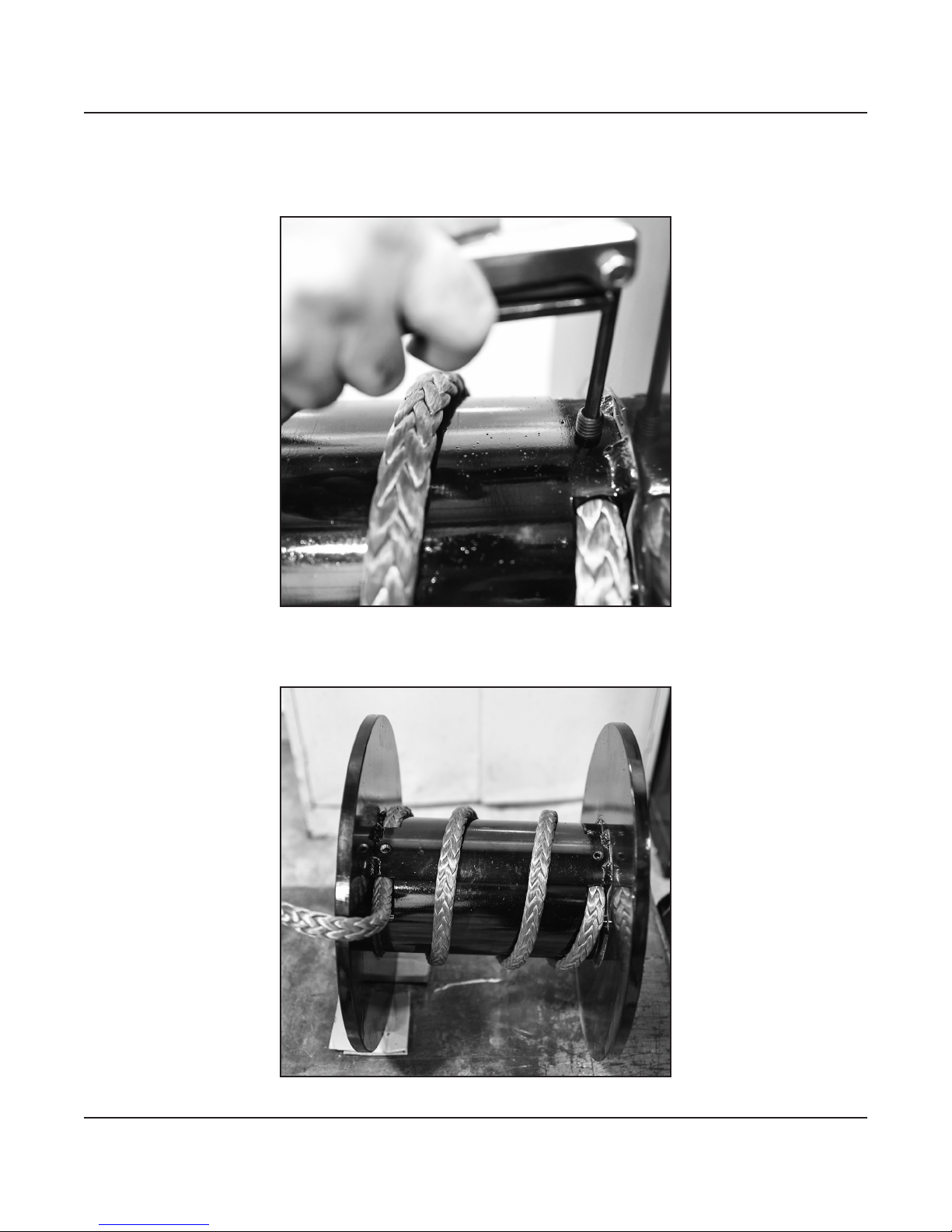

SYNTHETIC ROPE

The roller tensioner must be removed to use synthetic rope.

1.Useonly12strand(HMPE)highmoduluspolyurethanebercoatedsyntheticrope,commonly

known as Dyneema (MBS 58,000 lbs.). Maximum Winch capacity is 250 ft. of 3/4” rope.

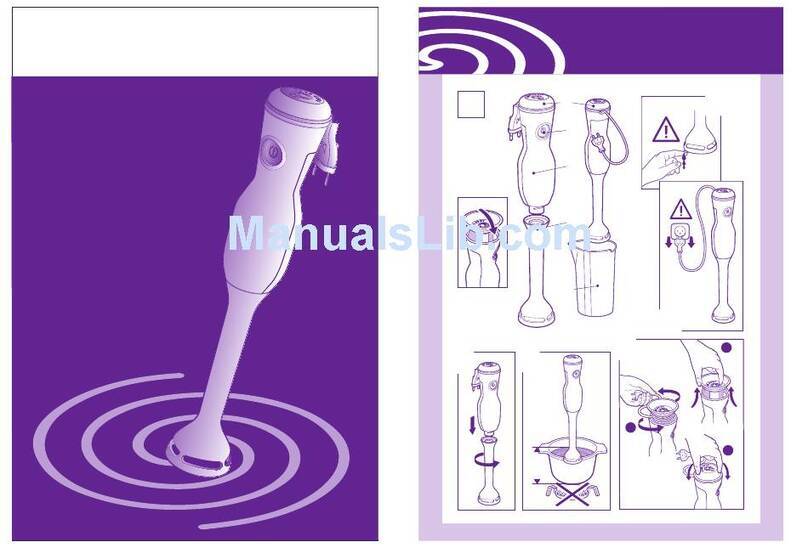

2. Install and anchor synthetic rope as shown below.

WARNING

NOTICE