1

RAMSEY HYDRAULIC PLANETARY WINCH MODEL POWERMASTER 20K

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most efficient operation from your Ramsey Winch, and safety

procedures one needs to know before operating a Ramsey Winch. Do not operate this winch until you have carefully

read and understand the "WARNINGS" and "OPERATION" sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch we make.

If the need should arise, warranty procedure is outlined on the back of your self-addressed postage paid warranty card.

Please read and fill out the enclosed warranty card and send it to Ramsey Winch Company. If you have any problems

with your winch, please follow instructions for prompt service on all warranty claims. Refer to back page for limited

warranty.

SPECIFICATIONS*

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope ratings.

WARNINGS:

CLUTCH MUST BE FULLY ENGAGED BEFORE STARTING THE WINCHING OPERATION.

DO NOT START WINCH MOTOR BEFORE ENGAGING CLUTCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PEOPLE.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

CABLE ANCHOR IS NOT DESIGNED TO HOLD LOAD.

Rated Line Pull (lbs.) …………………………………………………………………………. 20,000

(Kg.) …………………………………………………………….. 9070

Gear Reduction ……………………………………………………………… 21:1

Weight (without cable) 20K Bumper Winch (Less Bumper)…………….…………. 337 lbs

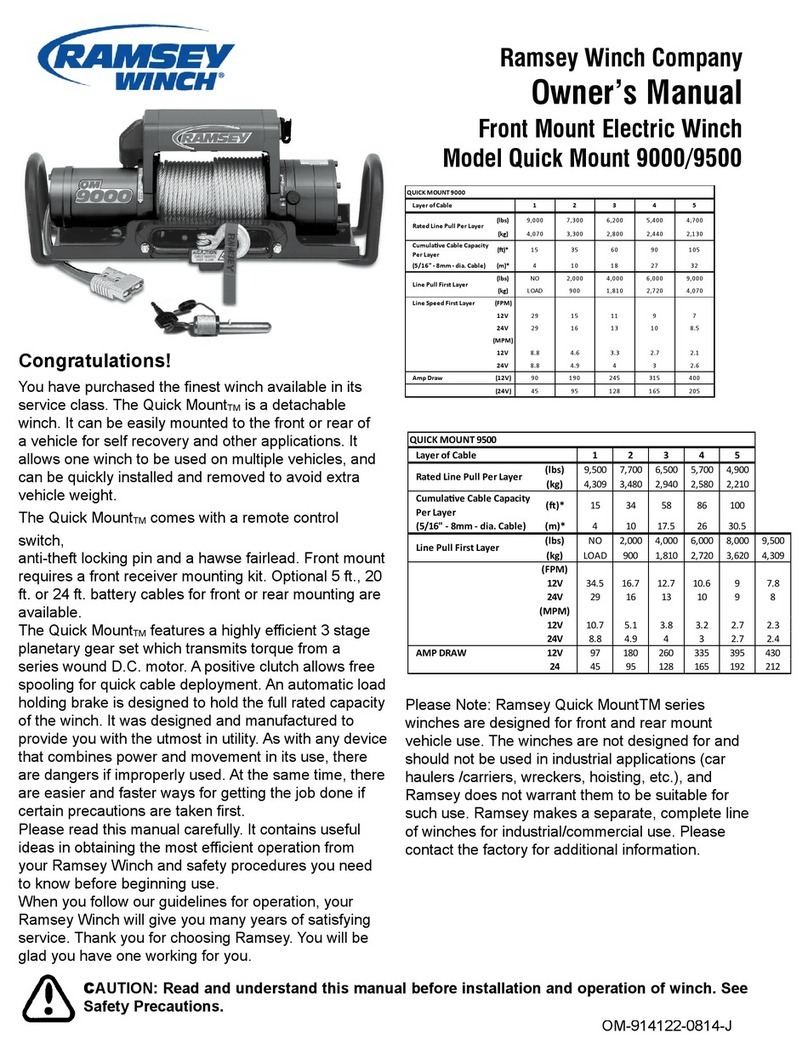

LAYER OF CABLE 1 2 3 4 5

*Rated line pull

per layer lbs. 20,000 17,300 15,200 13,600 12,300

Kg. 9,070 7,840 6,890 6,160 5,570

* Cable Capacity per Layer

20K Winch ft. 30 70 115 165 220

m 9 21 35 20 67

* Line Speed

(at 30 GPM) FPM 42 47 53 59 65

MPM 12.1 13.6 15.5 17 18.8

* These specifications are based on recommended wire rope of 9/16" Extra Improved Plow

Steel and a 14.9 cu. in. / Rev. motor.