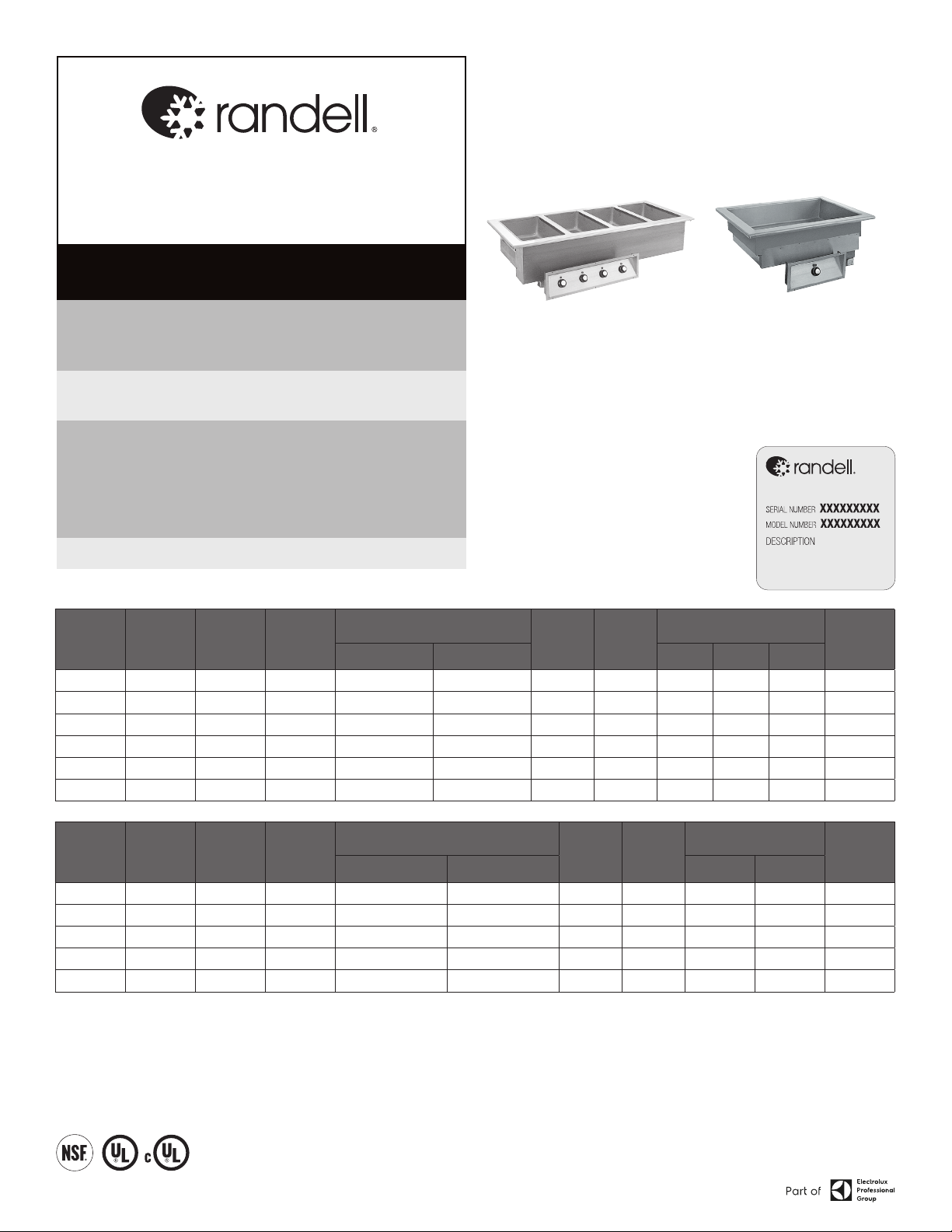

3 OM-9560 & 9570 DROP-IN SERIES HEATED WELLS

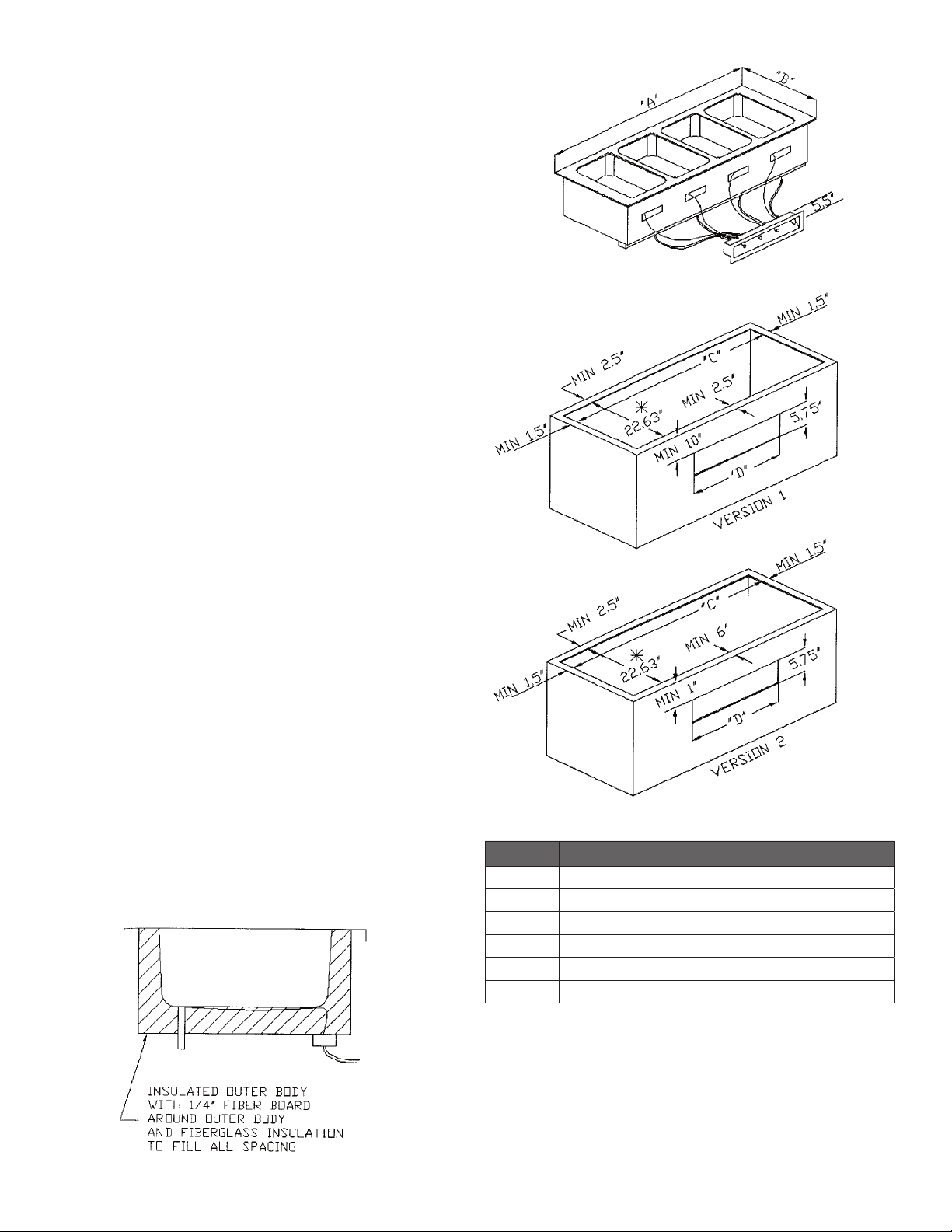

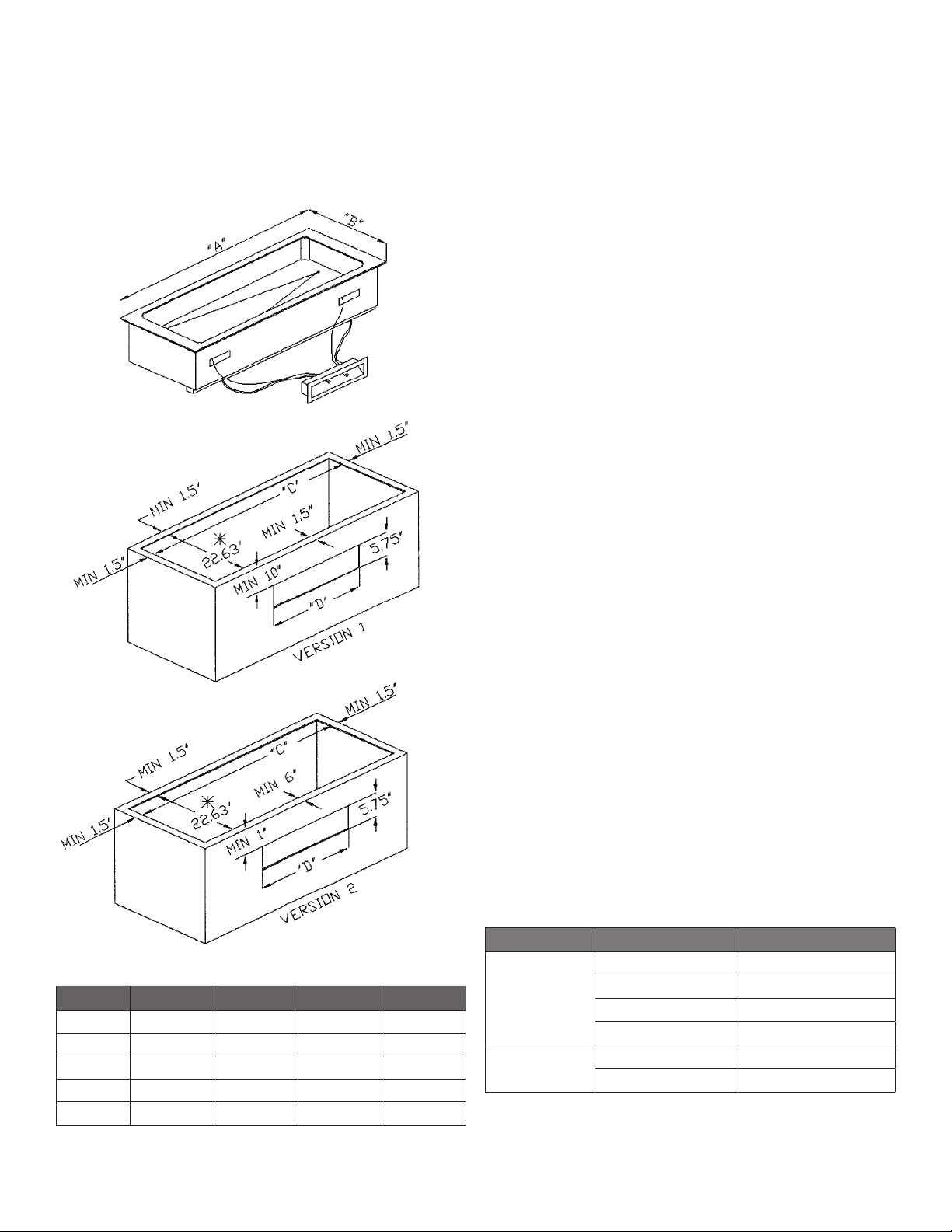

9570 INSTALLATION

1. When installing Model 9570 Drop-in Hot Food unit, a clearance of 1.5”

on all sides and 6” clearance below the unit must be maintained from all

combustible materials.

2. Control panel must be inserted into front cutout before main unit is installed.

3. Secure unit to top and seal with NSF approved silicon.

INSTALLATION REQUIREMENTS

MODEL “A” “B” “C” “D”

9570-2 31.25” 26” 28.25” 14”

9570-3 43.75” 26” 40.75” 14”

9570-4 56.5” 26” 53.375” 14”

9570-5 69.25” 26” 66.25” 14”

9570-6 82” 26” 78.9375” 14”

* REVISED CUTOUT SIZE FROM 22.5” TO 22.63” 10-18-95

OPERATION

All units are designed for 145° to 175° operation or 140° to 170° product

temperature. When using the unit dry expect at least a 15° drop in product

temperatures compared to using it wet. Electric hot food holding units may be

operated utilizing water or dry. Wet operation is usually recommended for higher

efficiency.

Plumbing: The units drain must have an outlet to an appropriate drainage area

or container.

Note: Drains must be plumbed to all applicable local code requirements.

Caution: Moisture collecting from improper drainage can create a slippery surface

on the floor and a hazard to employees. When making electrical connections refer

to the amperage data listed on the units data plate. Your local code or the national

electrical code handbook to be sure the unit is connected to the proper power source.

PREVENTATIVE MAINTENANCE

Randell strongly suggests a preventive maintenance program which would include

the following procedures:

1. Clean your hot food unit with a solution of warm water and a mild detergent.

The stainless steel portion of your unit can be polished with any quality

polish.

2. Drain water from wells daily and wipe them out. Clean wells thoroughly

twice a week to help insure a longer life for your wells.

Note: Do not use chemicals, steel wool or scrapers to clean unit.

Caution: Do not use abrasive cleaning solvents.

Proper maintenance of equipment is necessary to prevent costly repairs.

By evaluating each unit on a regular schedule you can often catch and repair

minor problems before they completely disable the unit. For more information

on preventive maintenance consult your local service company or www.CFESA.

com. Most repair companies offer this service at very reasonable rates to allow

you the time you need to run your business along with the peace of mind that

all your equipment will last throughout its expected life. These services often

offer guarantees as well as the flexibility in scheduling of maintenance for your

convenience. Randell believes strongly in the products it manufacturers and backs

those products with one of the best warranties in the industry. We believe with the

proper maintenance and use you will realize a profitable return on your investment

and years of satisfied service.

TROUBLESHOOTING

An electric hot food table operates on 120V, 208V or 240V circuits. It draws

power through either a fuse or circuit breaker panel; if you suspect an electri-

cal problem, check there first. The heating elements are controlled by electrical

temperature controls which sense and regulate temperature.

The following trouble shooting guide list the most common malfunctions in order

from most to least likely.

SYMPTOM POSSIBLE CAUSE PROCEDURE

Unit will not heat

Thermostat off Turn on

Unit unplugged Plug in unit

Circuit breaker tripped Replace breaker

Unknown problem Call preferred service agency

Individual well will

not heat

Thermostat off Turn on

Unknown problem Call preferred service agency

CONTACT US

If you have questions pertaining to the content in this manual, contact Randell

at 888-994-7636.