3 OM-PHHC-26 HOT HOLDING CABINET

ENTERING CONTROLLER PROGRAM MODE

1. Enter the Programming mode by pressing the “Set” and Arrow for 3

seconds. (the Fahrenheit symbol “F” will start blinking)

NOTE: If “of” appears the control is locked. Proceed to Unlocking the Keyboard

to unlock.

2. Enter full programming mode by again pressing the “Set” and Arrow for

8 seconds until L2 appears. Release the buttons and “HY” will appear with

a decimal point between the “H” and “Y” at the bottom. This indicates the

control is now in full programming mode.

3. While “HY” is on display push once and release.

4. “LS” will appear on display (this is the low set point)

5. Push and release “SET” once to view the current LS set point.

6. Continue this procedure of pushing “Set” and releasing to see the next code

on the sheet and the corresponding parameter for that code.

7. Should a parameter need to be changed you may use the or to get to

the desired new parameter.

8. Once the desired new parameter setting is achieved push and release “SET”

once. The new parameter will flash 3 times indicating the new parameter is

locked in.

9. After the parameter is locked in the control will then drop to the next code on

the chart. Continue by pushing the “Set” button to view the parameter of that

code.

10. Proceed until you have reached “HY” again.

11. Do not push any buttons for 8 seconds.

12. Once the temperature is displayed on the control you are now out of

programming mode,

13. You may now lock the keyboard if desired. Proceed to How to Lock the

Keyboard.

UNLOCKING THE KEYBOARD

1. Keep pressed together for more than 3 seconds the and keys until the

“on” message will be displayed.

LOCKING THE KEYBOARD

1. Keep pressed for more than 3 seconds the and keys.

2. The “of” message will be displayed and the keyboard will be locked. At this

point it will be possible only to see the set point or the MAX or Min temperature

stored.

3. If a key is pressed more than 3 seconds the “of” message will be displayed.

NOTE: Do not change parameters of control without consulting with Randell

Technical Support – 1.800.621.8560. Option 3.

PREVENTIVE MAINTENANCE

WARNING: DO NOT USE SHARP UTENSILS AND/OR OBJECTS.

WARNING: DO NOT USE STEEL PADS, WIRE BRUSHES, SCRAPERS, OR CHLORIDE

CLEANERS TO CLEAN YOUR STAINLESS STEEL.

CAUTION: DO NOT USE ABRASIVE CLEANING SOLVENTS, AND NEVER USE

HYDROCHLORIC ACID (MURIATIC ACID) ON STAINLESS STEEL.

Randell strongly suggests a preventive maintenance program which would include

the following procedures:

1. Clean all gaskets on a weekly basis with a solution of warm water and a mild

detergent to extend gasket life.

2. Wipe out any debris that has fallen into the cabinet on a daily basis.

3. Clean fan blades on a quarterly basis. It is recommended this be performed

by an authorized service agent.

Recommended cleaners for your stainless steel include the following:

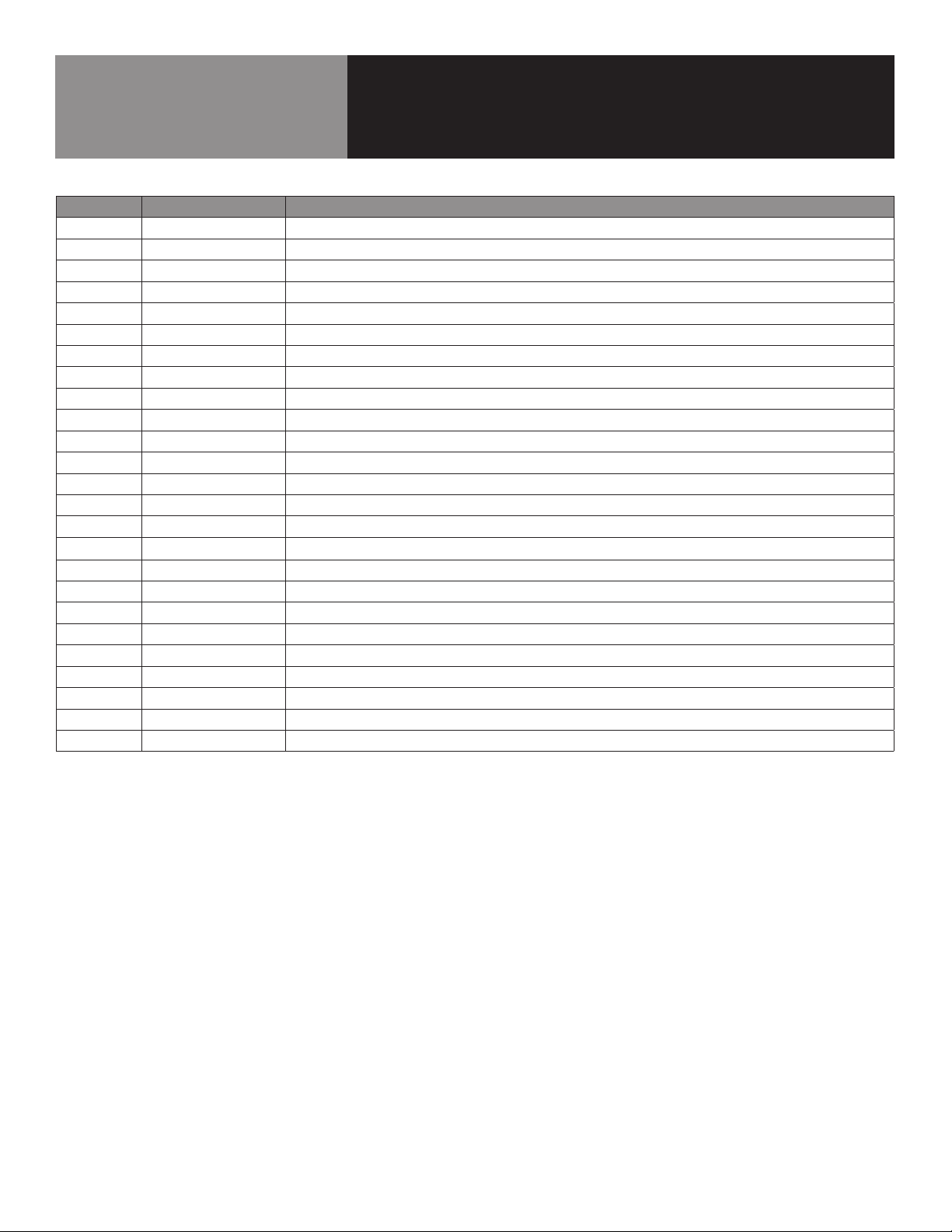

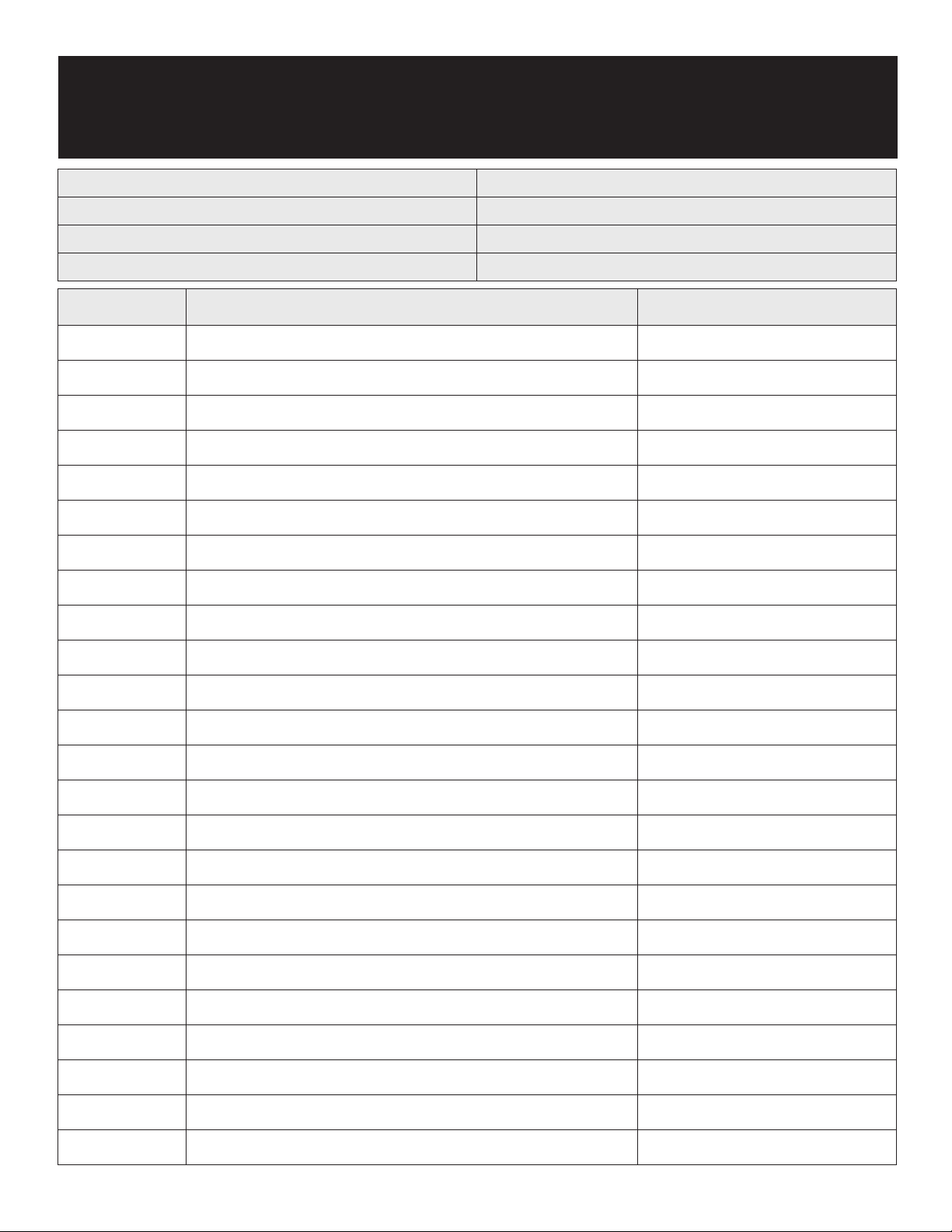

JOB CLEANING AGENT COMMENTS

Routine cleaning Soap, ammonia,

detergent Medallion

Apply with a sponge or

cloth

Fingerprints and smears Arcal 20, Lac-O-Nu,

Ecoshine Provides a barrier film

Stubborn stains and

discoloration

Cameo, Talc, Zud,

First Impression

Rub in the direction of

the polish lines

Greasy and fatty acids, blood,

burnt-on foods

Easy-Off, Degrease It,

Oven Aid

Excellent removal on all

finishes

Grease and Oil Any good commercial

detergent

Apply with a sponge or

cloth

Restoration/Preservation Benefit, Super Sheen Good idea monthly

Reference: Nickel Development Institute, Diversey Lever, Savin, Ecolab, NAFEM

REPLACEMENT PARTS

To order parts, contact your Authorized Service Agent. Supply the model

designation, serial number, part description, part number, quantity, and when

applicable, voltage and phase.

CONTACT US

If you have questions pertaining to the content in this manual, contact Randell

at 888-994-7636.

TROUBLESHOOTING

This unit is designed to operate smoothly and efficiently if properly maintained.

However, the following is a list of checks to make in the event of a problem. Wir-

ing diagrams are found at the end of this manual. When in doubt, turn unit off

and contact service at 888-994-7636.

SYMPTOM POSSIBLE CAUSE PROCEDURE

Unit doesn’t heat

No power to unit Plug in unit

Temperature control turned

off Check temperature control

Temperature control faulty Test temperature control

High limit device Test high limit

Heating element faulty Test element

Control Error

Flashing HA Unit too hot / check probe

Flashing LA Unit too cool / check door

closure

Flashing P1 Check probe connection

Unit too hot

Temperature control too

high Adjust temperature control

Temperature control Test temperature control

Unit not hot enough

Door not sealing Inspect gasket & door hinges

Fan motor Raise temperature setting

Temperature control Adjust temperature control

Element Test elements