The firebox should be filled to the recommended level of

the bottom firebox door opening and the firebox door

closed.

A correctly fully fire will last a minimum of 2 hours when

burning solid fuel and 1 hour burning wood when

maintaining the maximum rated output of the boiler with

intermittent cooking periods included.

NOTE: When burning all recommended fuels other

than Sunbrite Coke, the secondary air slide should

be set in a fully open position.

A deep bed of newly charged fuel on a low fire will

take time before heat reaches the ovens, hotplate

and boiler. When burning Coal, Phurnacite and

Anthracite, allow several minutes for the new charge

to ignite before changing the flue chamber damper

setting.

ONCE REFUELLING HAS BEEN COMPLETED,

CLOSE THE FIREBOX DOOR IMMEDIATELY AND

OPEN ONLY FOR REFUELLING CHARGES.

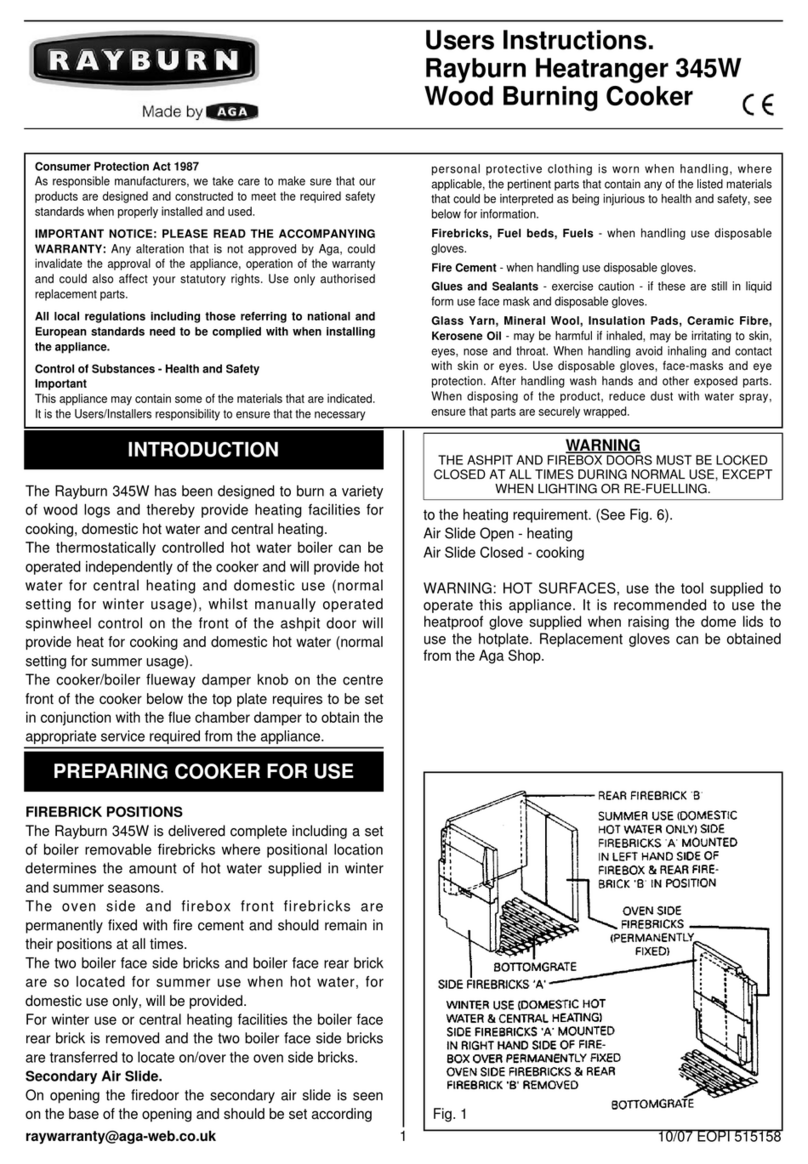

To de-ash, riddle the grate by agitating the riddling

handle in an up and down manner about 20 times to free

the grate of ash. See Fig. 8.

ALWAYS DE-ASH BEFORE REFUELLING (SEE

‘EXCEPTIONS’ BELOW) AT THE FOLLOWING

INTERVALS:-

SUMMER USE:

Three times daily at least.

WINTER USE:

Three time daily at least and more often if required.

NOTE: SHOULD THE BOTTOMGRATE DE-ASHING

FAIL TO CLEAR AN ACCUMULATION OF STONES,

SHALE OR CLINKER, IT MAY BE REMOVED AS

DESCRIBED IN SECTION ON REMOVAL OF

CLINKER.

Open the ashpit door to give access to the ashpan which

must be emptied regularly (See Fig. 9).

In winter, this may be as much as three times daily

depending on weather severity.

The class of fuel and cooker usage govern the frequency

of refuelling.

NOTE: DO NOT ALLOW ASH TO ACCUMULATE IN

THE ASHPAN UNTIL UNTIL IT TOUCHES THE

UNDERSIDE OF THE BOTTOMGRATE BARS OR

THEY WILL QUICKLY BURN OUT.

Ensure the ashpan is fully home otherwise the ashpit

door may not close and lock completely.

EXCEPTIONS:

WHEN BURNING ANTHRACITE OR PHURNACITE,

ALWAYS REFUEL BEFORE EMPTYING ASHPAN AND

RIDDLING.

Due to an accumulation of pieces of stone, clinker and

shale etc. it may not be possible to pass them through

the grate when riddling, and may even cause jamming.

Allow the fire to burn out and then open the ashpit door.

Lift off the clinker door (See Fig. 10) and insert hooked

poker to drawn out any offending accumulation. Replace

clinker door after use.

The amount of clinker formation is dependent on the

heating load or burning rate and should be checked

weekly for any build-up. Excessive build-up will lead to a

fall in heating output requiring bottomgrate clean-out and

reduction in life of the bottomgrate.

The best results can be obtained by using machined

base utensils. The hottest part of the hot plate is

immediately above the fire, the other end being for

simmering.

The circular plug in the hotplate (near the flue chamber

end) is for flue cleaning and must not be removed for

cooking.

Keep the hotplate clean with a wire brush.

NOTE: TO OBTAIN OPTIMUM HOTPLATE

PERFORMANCE FOR FAST BOILING OR HOT PLATE

COOKING, FUEL THE FIREBOX TO THE BOTTOM

EDGE OF THE FIREBOX APERTURE TO A

HORIZONTAL LEVEL.

WARNING: THE COOKER TOP PLATE SURFACE

AROUND THE HOTPLATE WILL BECOME HOT

UNDER USE AND CARE MUST BE OBSERVED.

The correct adjustment of the spinwheel and flue

chamber damper to obtain the oven temperature required

varies with the chimney draught, and can be found only

by experiment. The following is a suggested method

only, and may need modification to suit local conditions.

Suppose an oven temperature for roasting is desired,

and that the cooker is idling.

Thoroughly de-ash the fire as described in the respective

paragraph, and refuel. Set the flue chamber damper to

No.3 setting and open the spinwheel as described under

‘CONTROL SETTING’.

As soon as the fire has become red all through, close the

flue chamber damper. Do not allow the fire to become

white hot.

The temperature of the oven should now rise steadily.

When it reaches a point about 30ÞC (50ÞF) below that

required, close the spinwheel to approximately one turn

open. Thereafter control the temperature of the oven by

adjusting the spinwheel.

NOTE: THE METHOD SHOULD PROVE SUCCESSFUL

IN ALMOST ALL CASES, BUT IF CLOSING THE FLUE

DE-ASHING

REMOVAL OF CLINKER

FROM BOTTOMGRATE

USE OF THE HOT PLATE

6

USE OF THE TOP

ROASTING OVEN

REFUELLING