immediately above the fire, the other end is for simmering.

The plug in the hotplate at the flue chamber end is for flue

cleaning and should not be removed for cooking or when

the cooker is fired.

NOTE: IN ORDER TO OBTAIN AN OPTIMUM HOT

PLATE PERFORMANCE FOR FAST BOILING OR HOT

PLATE COOKING, FUEL THE FIREBOX TO THE

BOTTOM EDGE OF THE FULLING APERTURE TO A

HORIZONTAL LEVEL.

WARNING: THE COOKER TOP PLATE SURFACE

AROUND THE HOTPLATE WILL BECOME HOT UNDER

USE AND CARE MUST BE OBSERVED. PLEASE

REFER TO THE INSTALLATION INSTRUCTIONS

REGARDING MINIMUM CLEARANCES TO

COMBUSTIBLE SURFACES AND MATERIALS.

Wood

The cooker is designed for continuous slumbering

overnight up to a maximum of 12 hours depending on the

type of dry wood being used.

Last thing at night, open the chimney damper, riddle the

fire, empty the ashpan and refuel as described under

“Fuelling”. Ensure that the ashpit door is securely

closed, spinwheel is closed and opened a 1/4 turn and

the damper is closed to its No.1 setting.

Turn the pivoted dilution lever (on the bottom front flue

chamber door) Fig. 9 from left to right hand side so that

the door opens at the bottom and minimises the burning

rate and chimney condensation.

NOTE: THE PRECISE AMOUNT OF OPENING

DEPENDS ON THE CHIMNEY DRAUGHT AND MAY

TAKE 2 OR 3 DAYS TO ASCERTAIN IN CONJUNCTION

WITH THE TYPE/CONDITION OF WOOD BEING

BURNT.

1. If the fuel in the firebox is exhausted prematurely, the

overnight chimney draught must be reduced by further

opening of the flue chamber door.

2. If the fuel does not burn but ‘dies out’ the draught

should be increased by partly closing the flue chamber

door. In the morning, close the flue chamber door, open

the spinwheel and damper and fuel the fire. Immediately

the new fuel has caught alight, riddle the fire and close the

damper.

NOTE: BUILD-UP OF CREOSOTE DEPOSITS IN THE

FLUE AND CHIMNEY CAN IN TIME, LEAD TO

CHIMNEY FIRES. THESE DEPOSITS CAN BE

PREVENTED BY THE REGULAR USE OF A

PROPRIETARY BRAND OF CHEMICAL CREOSOTE

REMOVER CHIMNEY CLEANER SUCH AS ”ATTACK”

WHICH REDUCES THE ADHESION STRENGTH OF

THE CREOSOTE DEPOSITS, CAUSING THEM TO

FALL.

IMPORTANT: CHEMICAL CLEANERS MUST NOT BE

CONSIDERED AS AN ALTERNATIVE TO CHIMNEY

SWEEPING, ONLY AS SUPPLEMENTARY.

DO NOT CARRY OUT THIS OPERATION WITH THE

FIRE ALIGHT.

Solid Fuel

The cooker is designed for continuous burning and the

best results will only be obtained if it is allowed to burn

overnight. It is no more expensive in fuel. Last thing at

night open the chimney damper, riddle the fire, empty the

ashpan and refuel. Do not overload. Ensure that the

ashpit door is securely closed. Close the spinwheel

and reopen it a quarter of a turn.

THE BEST POSITION FOR THE CHIMNEY DAMPER

CAN BE FOUND ONLY BY EXPERIMENT, BUT FOR A

START TRY CLOSING IT TO No. 1 SETTING.

In the morning, open the spinwheel and damper and

riddle the fire. When it is burning, close damper, if the

hotplate is required immediately, lightly refuel before use.

EXCEPTIONS: WHEN BURNING ANTHRACITE OR

PHURNACITE ALWAYS REFUEL BEFORE EMPTYING

ASHPAN AND RIDDLING.

Open the chimney damper to its full extent and the ashpit

door. Engage the operating tool into the riddling lever

which projects through the ashpan front and push/pull the

lever in a back and forth motion to de-ash.

ALWAYS DE-ASH BEFORE REFUELLING (SEE

‘EXCEPTIONS’ BELOW AT THE FOLLOWING

INTERVALS).

SUMMER USE:

Three times daily at least.

WINTER USE:

Three time daily at least and more often if required.

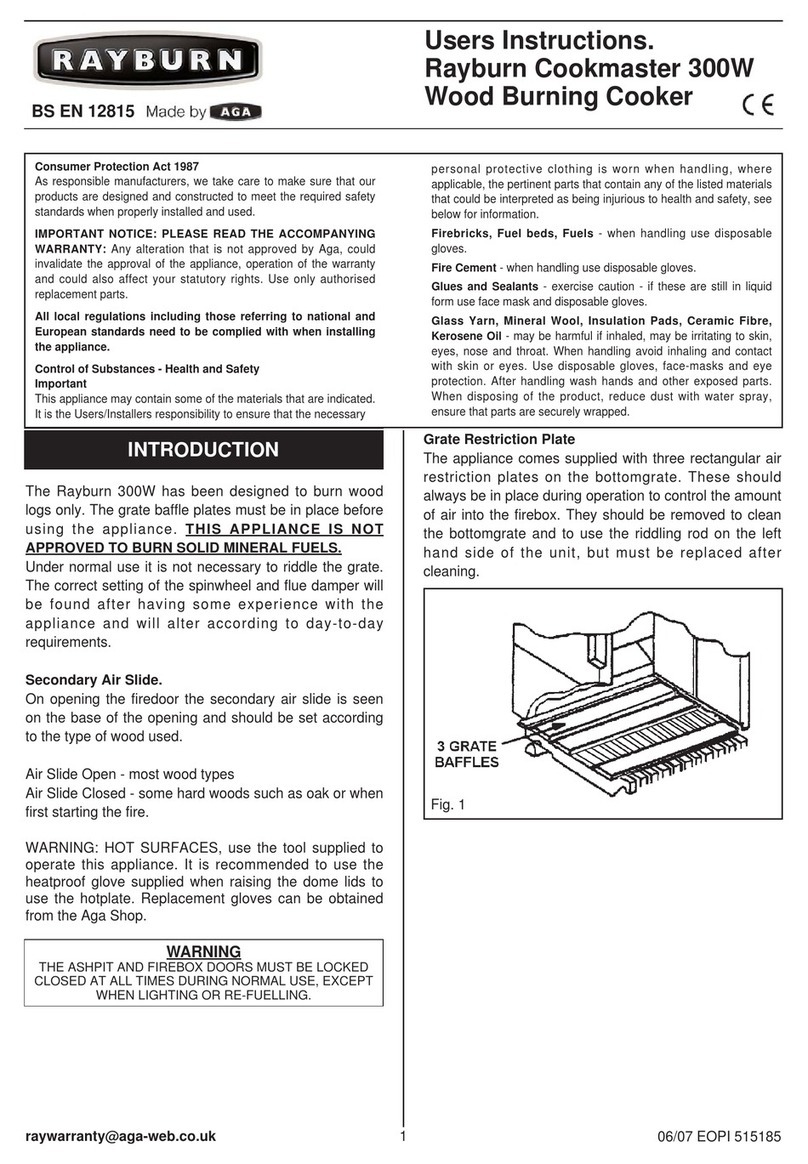

NOTE: SHOULD THE BOTTOMGRATE DE-ASHING

FAIL TO CLEAR AN ACCUMULATION OF STONES,

SHALE OR CLINKER, IT MAY BE REMOVED AS

DESCRIBED IN SECTION ‘REMOVAL OF CLINKER’.

Open the ashpit door to give access to the ashpan which

must be emptied regularly (See Fig. 8). In winter, this may

be more than three times daily depending on weather

severity. The class of fuel and cooker usage govern the

frequency of refuelling.

NOTE: DO NOT ALLOW ASH TO ACCUMULATE IN

THE ASHPAN UNTIL IT TOUCHES THE UNDERSIDE

OF THE BOTTOMGRATE BARS OR THEY WILL

QUICKLY BURN OUT.

Ensure the ashpan is fully home otherwise the ashpit

door may not close and lock completely.

Clinker Removal - ‘To Dump the Grate’.

1. Open the ashpit door and remove ashpan.

2. Insert wire tool into locating sockets of grate frame

(See Fig. 14) lifting hand holding end upwards until

grate frame is free of its supports. Taking the weight

of the grate frame, gently lower front of grate

assembly until it rests on ashpit bottom plate.

3. Remove clinker from sloping bottom grate either by

raking poker or tongs.

4. Lift tool upwards and replace front of grate in reverse

manner described in 2ensuring the grate frame is

securely supported and located.

5. Check that the reciprocating bars operate by

push/pulling the ridding lever with the tool.

6. Replace the ashpan and lock the ashpit door

securely.

OVERNIGHT BURNING

6