Contents

CONTENTS

1BASIC SAFETY INSTRUCTIONS..................................................................................4

1.1 Laser safety.....................................................................................................................4

1.2 Laser shutter ...................................................................................................................4

1.3 Signs................................................................................................................................4

1.4 Classification of laser devices.........................................................................................5

1.5 Laser area.......................................................................................................................6

1.6 Special hazards caused by mirrors made of beryllium ...................................................7

1.7 Special hazards caused by lenses made of zinc selenide..............................................7

2BASIC INFORMATION...................................................................................................8

2.1 Introduction......................................................................................................................8

2.2 Intended use....................................................................................................................8

2.3 Package contents............................................................................................................8

2.4 Module overview .............................................................................................................9

2.5 Warranty........................................................................................................................10

2.6 Manufacturer.................................................................................................................10

2.7 Customer support..........................................................................................................10

2.8 Status LEDs ..................................................................................................................11

3TECHNICAL DATA.......................................................................................................12

3.1 Rating plate code ..........................................................................................................12

3.1.1 Primary Name ...............................................................................................................12

3.1.2 Detailed Description......................................................................................................13

3.2 Conformity with directives .............................................................................................13

4FUNCTIONAL DESCRIPTION .....................................................................................14

4.1 Laser beam deflection unit............................................................................................14

4.2 F-Theta lens..................................................................................................................15

4.3 Digital interface..............................................................................................................16

4.4 Power supply.................................................................................................................17

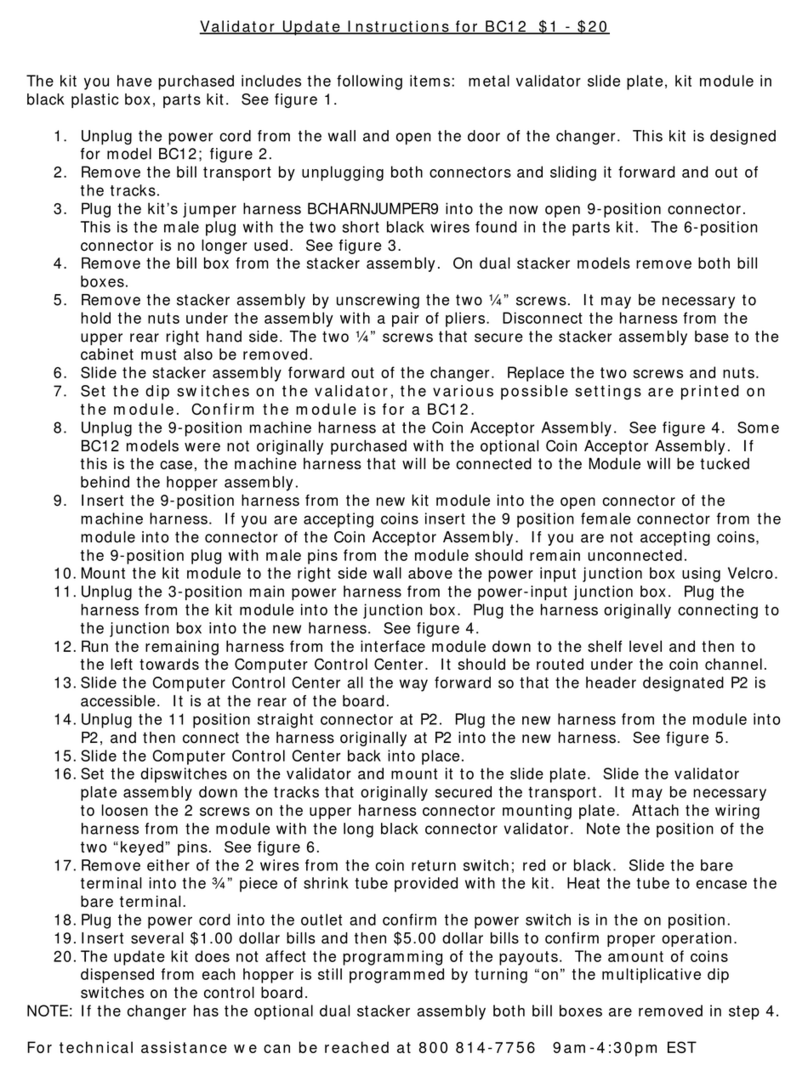

5INSTALLATION............................................................................................................18

6MAINTENANCE AND CLEANING...............................................................................19

6.1 Cleaning the housing.....................................................................................................19

6.2 Cleaning the optical system ..........................................................................................19

6.2.1 Instructions for cleaning lenses and protective glasses................................................20

6.2.2 Instructions for cleaning mirrors....................................................................................20

6.2.3 Special notes for mirrors made of beryllium and lenses made of zinc selenide...........21

7TROUBLESHOOTING..................................................................................................22

8DISPOSAL....................................................................................................................23

MN065_v1.0.1 2-Axis Laser Beam Deflection Unit SS-II 3