Validator Update Instructions for BC12 $1 - $20

The kit you have purchased includes the following items: metal validator slide plate, kit module in

black plastic box, parts kit. See figure 1.

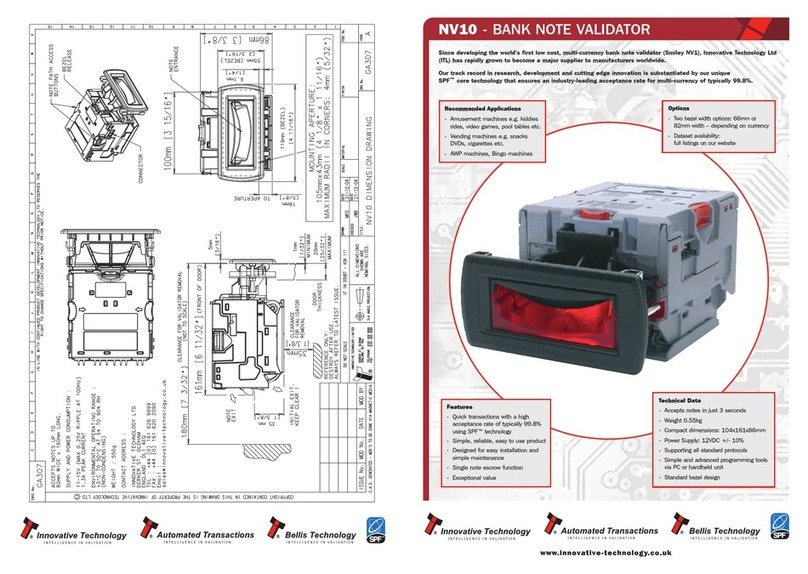

1. Unplug the power cord from the wall and open the door of the changer. This kit is designed

for model BC12; figure 2.

2. Remove the bill transport by unplugging both connectors and sliding it forward and out of

the tracks.

3. Plug the kit’s jumper harness BCHARNJUMPER9 into the now open 9-position connector.

This is the male plug with the two short black wires found in the parts kit. The 6-position

connector is no longer used. See figure 3.

4. Remove the bill box from the stacker assembly. On dual stacker models remove both bill

boxes.

5. Remove the stacker assembly by unscrewing the two ¼” screws. It may be necessary to

hold the nuts under the assembly with a pair of pliers. Disconnect the harness from the

upper rear right hand side. The two ¼” screws that secure the stacker assembly base to the

cabinet must also be removed.

6. Slide the stacker assembly forward out of the changer. Replace the two screws and nuts.

7. Set the dip switches on the validator, the various possible settings are printed on

the module. Confirm the module is for a BC12.

8. Unplug the 9-position machine harness at the Coin Acceptor Assembly. See figure 4. Some

BC12 models were not originally purchased with the optional Coin Acceptor Assembly. If

this is the case, the machine harness that will be connected to the Module will be tucked

behind the hopper assembly.

9. Insert the 9-position harness from the new kit module into the open connector of the

machine harness. If you are accepting coins insert the 9 position female connector from the

module into the connector of the Coin Acceptor Assembly. If you are not accepting coins,

the 9-position plug with male pins from the module should remain unconnected.

10.Mount the kit module to the right side wall above the power input junction box using Velcro.

11.Unplug the 3-position main power harness from the power-input junction box. Plug the

harness from the kit module into the junction box. Plug the harness originally connecting to

the junction box into the new harness. See figure 4.

12.Run the remaining harness from the interface module down to the shelf level and then to

the left towards the Computer Control Center. It should be routed under the coin channel.

13.Slide the Computer Control Center all the way forward so that the header designated P2 is

accessible. It is at the rear of the board.

14.Unplug the 11 position straight connector at P2. Plug the new harness from the module into

P2, and then connect the harness originally at P2 into the new harness. See figure 5.

15.Slide the Computer Control Center back into place.

16.Set the dipswitches on the validator and mount it to the slide plate. Slide the validator

plate assembly down the tracks that originally secured the transport. It may be necessary

to loosen the 2 screws on the upper harness connector mounting plate. Attach the wiring

harness from the module with the long black connector validator. Note the position of the

two “keyed” pins. See figure 6.

17.Remove either of the 2 wires from the coin return switch; red or black. Slide the bare

terminal into the ¾” piece of shrink tube provided with the kit. Heat the tube to encase the

bare terminal.

18.Plug the power cord into the outlet and confirm the power switch is in the on position.

19.Insert several $1.00 dollar bills and then $5.00 dollar bills to confirm proper operation.

20.The update kit does not affect the programming of the payouts. The amount of coins

dispensed from each hopper is still programmed by turning “on” the multiplicative dip

switches on the control board.

NOTE: If the changer has the optional dual stacker assembly both bill boxes are removed in step 4.

For technical assistance we can be reached at 800 814-7756 9am-4:30pm EST