Index

1Summary.................................................................................................................................. 4

1.1 Structure................................................................................................................................4

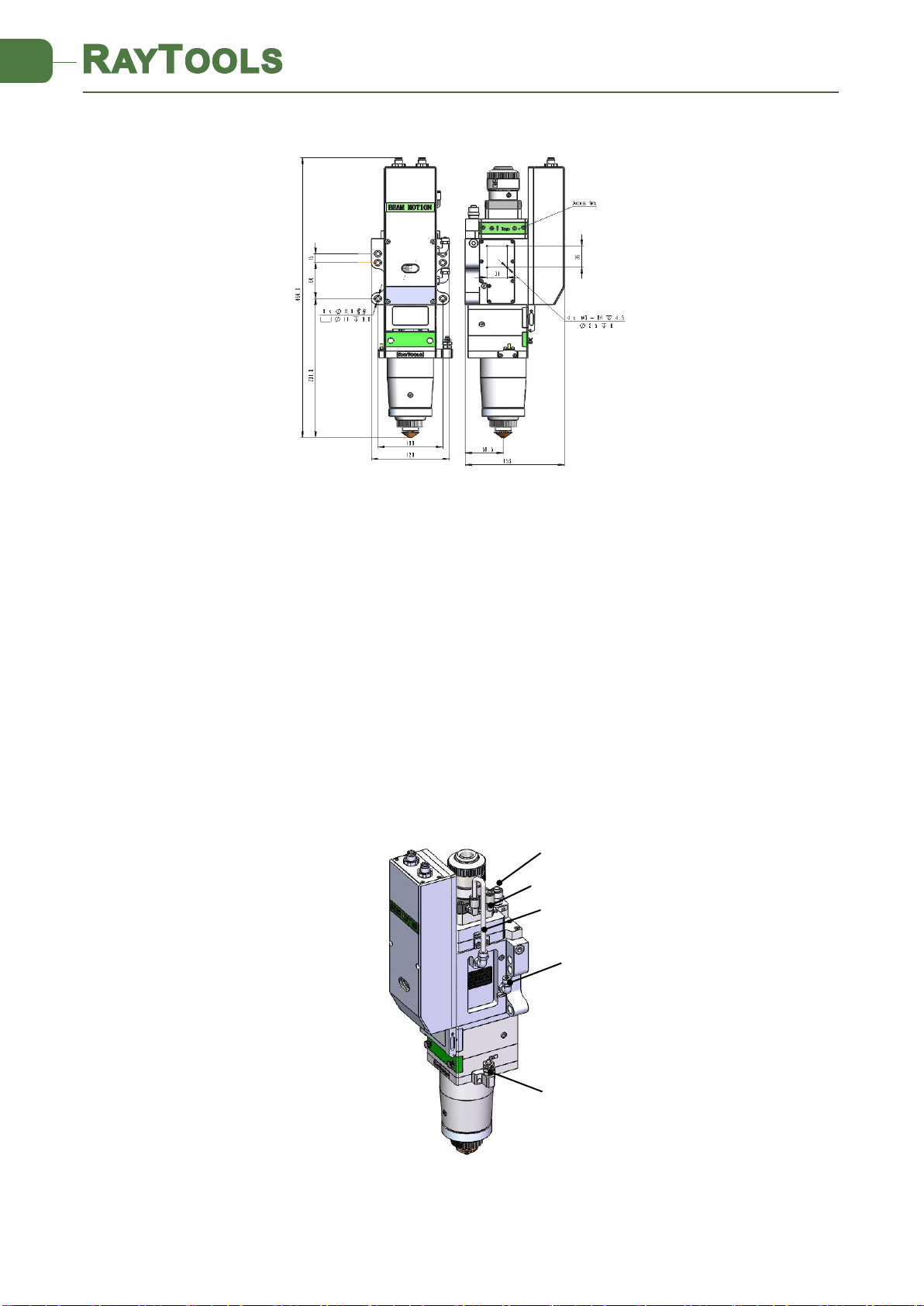

2Mechanical Installation............................................................................................................ 4

2.1 Mounting ...............................................................................................................................4

2.2 Connection of Water Pipe and Gas Pipe ...............................................................................5

2.2.1 Water cooling interface ........................................................................................5

2.2.2 Assist gas interface ...............................................................................................6

2.3 Connection of Cutting Head Cable ........................................................................................7

2.3.1 Connection of Cutting Head and Cable ................................................................7

2.3.2 Cable connection to drive ....................................................................................7

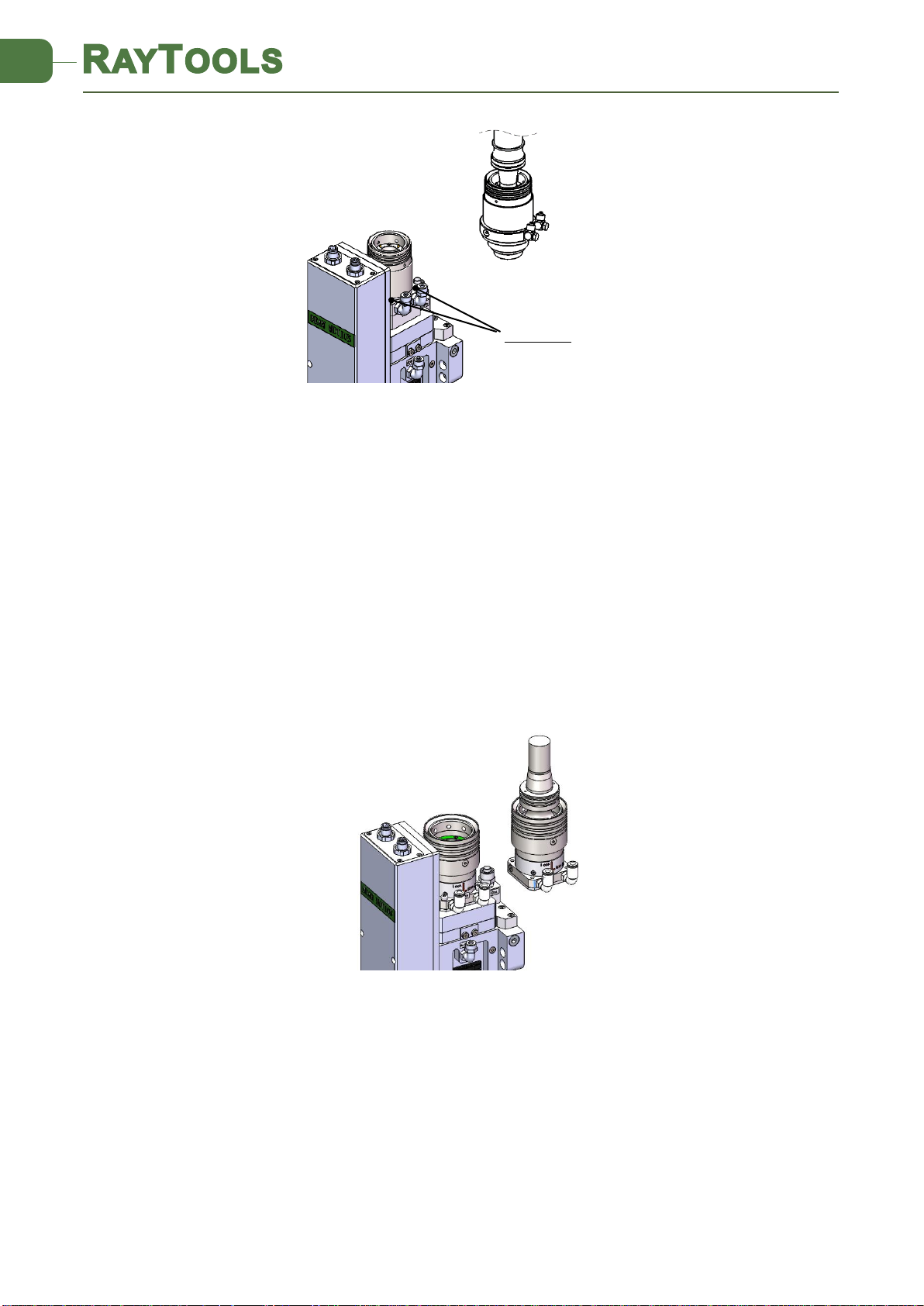

2.4 Fiber Input Interface..............................................................................................................7

2.5 Fiber Insertion and Interface Direction Adjustment .............................................................8

3System Installation and Commissioning ..................................................................................9

3.1 ETC_F100 Installation (Auto focus by 0-10V analog) ............................................................9

3.1.1 Interface & Signal ...............................................................................................10

3.1.2 Wiring .................................................................................................................11

3.1.3 Dimension of ETC_F100......................................................................................13

3.1.4 Dimension of Drive.............................................................................................14

3.2 FSCUT (Cypcut) with position mode....................................................................................14

3.2.1 Wiring .................................................................................................................14

4Beam Adjustments and Focusing...........................................................................................17

4.1 Beam Adjustments (QBH interface) ....................................................................................17

4.2 The Focus Position Adjustment...........................................................................................18

5Maintenance..........................................................................................................................18

5.1 Cleaning Lens.......................................................................................................................18

5.2 Removal and Installation of Lenses .....................................................................................19

5.2.1 Removal and Installation of Cover Glass ............................................................19

5.2.2 Removal and Installation of Top Cover Glass .....................................................20

5.2.3 Removal and Installation of Collimating Lenses.................................................21

5.2.4 Removal and Installation of Focus Lenses..........................................................22

5.3 Replace Nozzle Connector...................................................................................................22

5.3.1 Replace Ceramic Body ........................................................................................23

5.3.2 Replace Nozzle....................................................................................................23

5.4 Troubleshooting of Drive .....................................................................................................23

5.4.1 Alarm information ..............................................................................................23

5.5 Common Problem Analysis..................................................................................................24

5.5.1 Servo calibration process terminated abnormally .............................................24

5.5.2 The screen is abnormally displayed ...................................................................25