Index

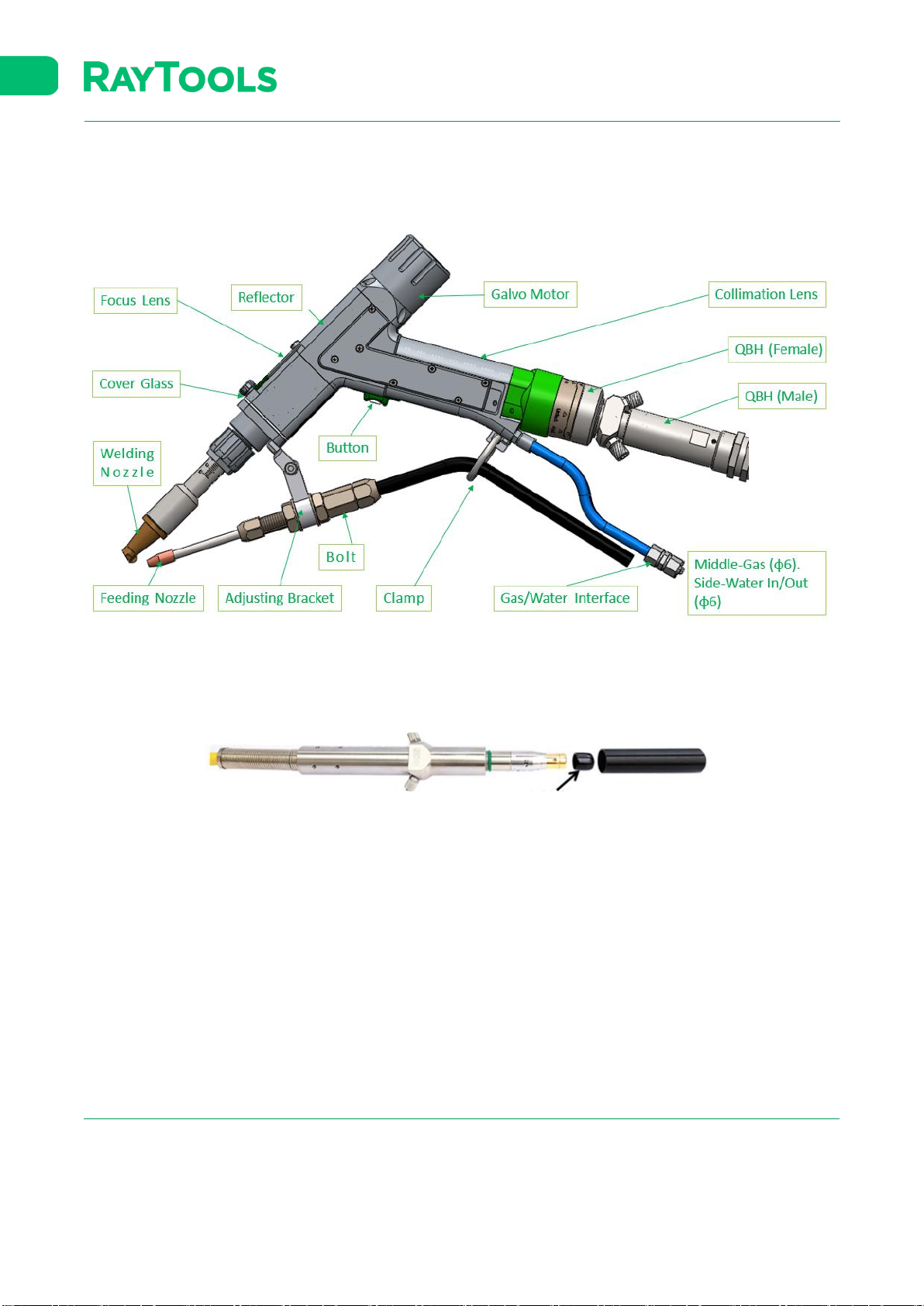

1Laser Processing Head ............................................................................................................1

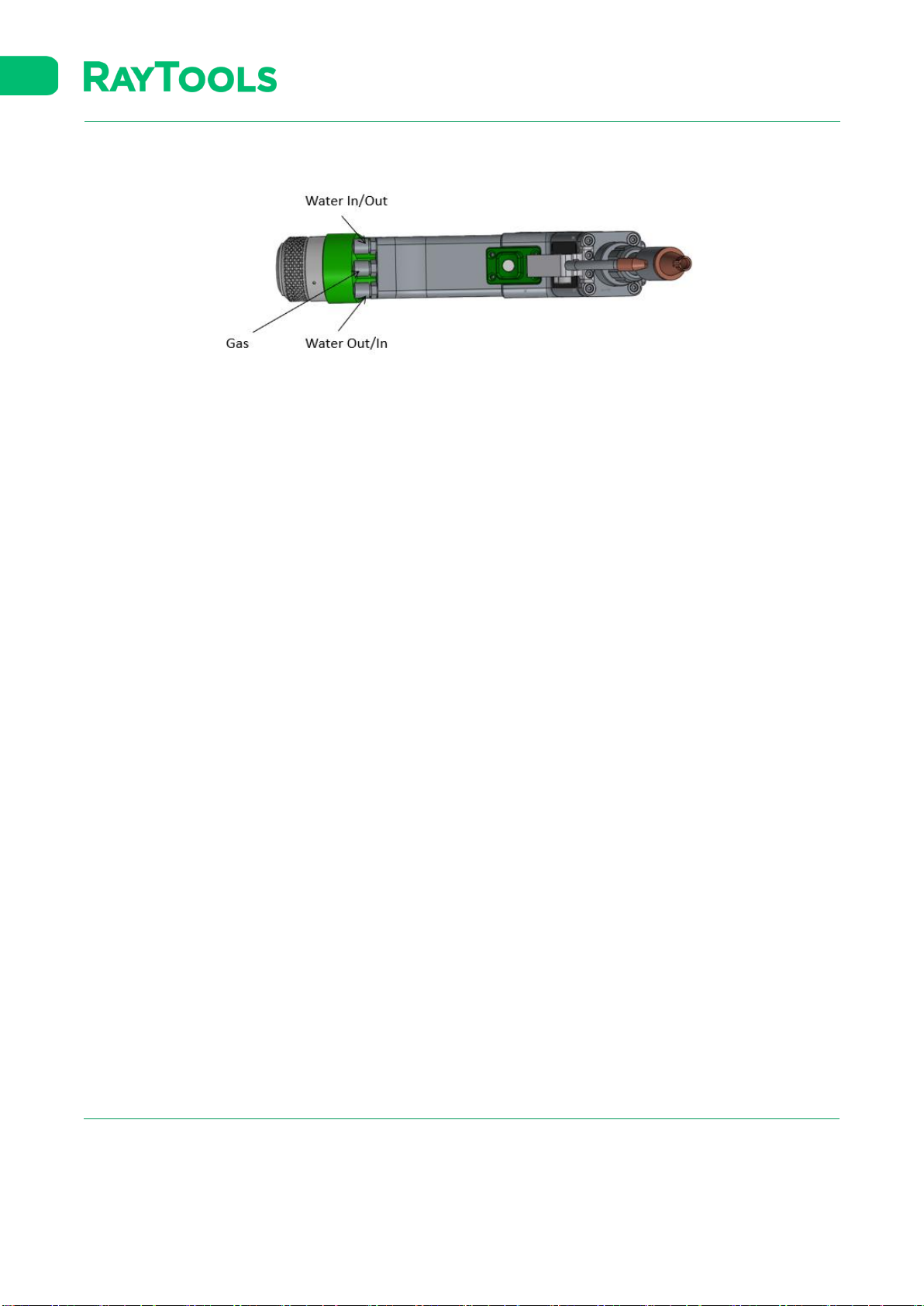

1.1 QBH Connection...................................................................................................................1

1.2 Dismantling and Mounting of Cover Glass...........................................................................2

1.3 Daily Inspection....................................................................................................................3

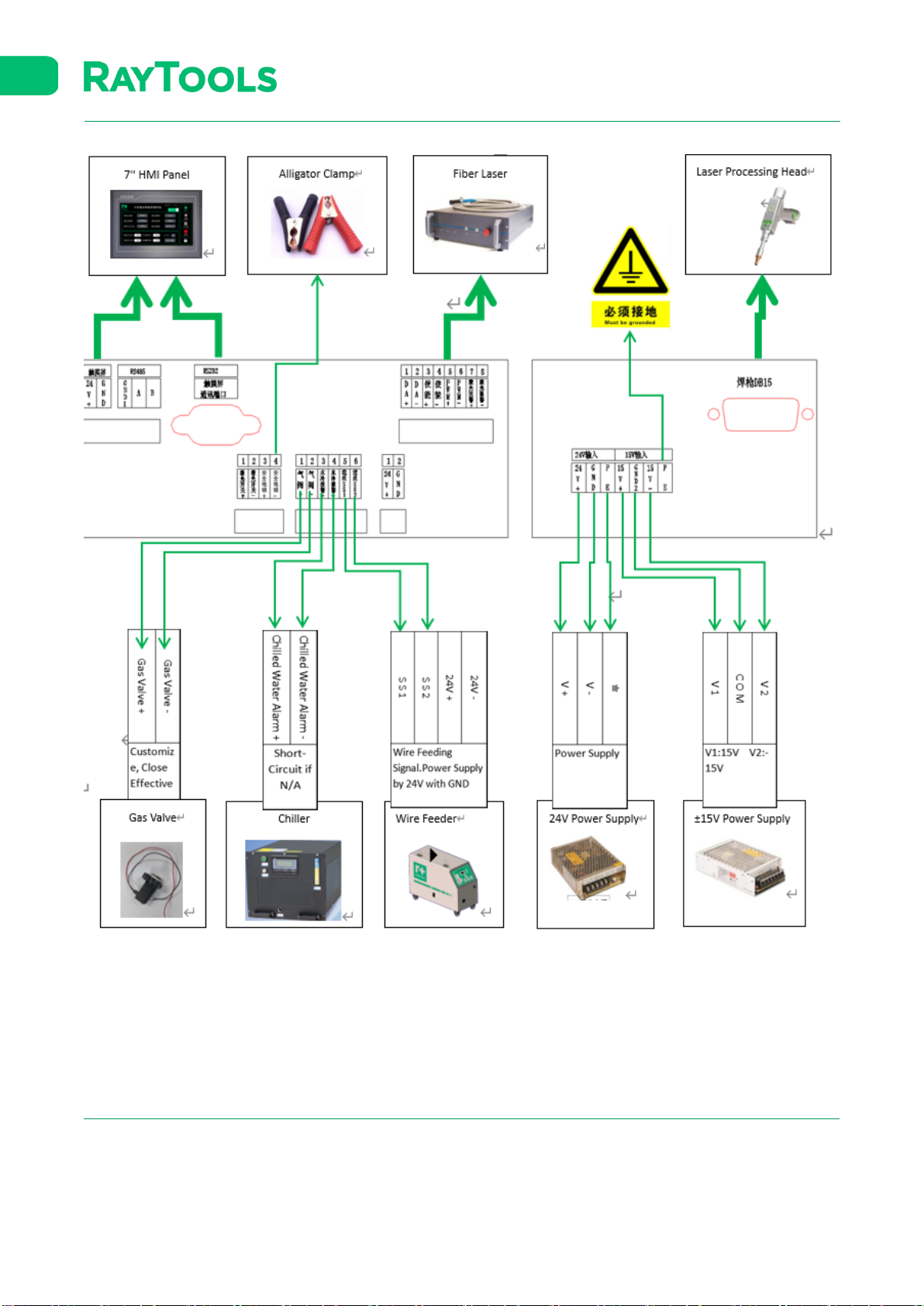

2Controller ................................................................................................................................4

2.1 Overall Wiring.......................................................................................................................4

2.2 Wiring from HMI Panel to Controller ...................................................................................6

2.3 Wiring from Laser to Controller ...........................................................................................6

2.4 Wiring from Laser Processing Head to Controller................................................................7

2.5 Wiring from Power Supply to Controller..............................................................................7

2.6 Wiring from Gas Valve and Chiller to Controller ..................................................................9

2.7 Wiring from Wire Feeder to Controller..............................................................................10

3Wire Feeder...........................................................................................................................10

3.1 Installation of Wire Feeder.................................................................................................11

3.2 Operation of Wire Feeder ..................................................................................................13

3.3 Troubleshooting of Wire Feeder ........................................................................................16

3.4 Daily Maintenance of Wire Feeder.....................................................................................17

3.5 Supplementary Regulation of Auto Wire Feeding..............................................................18

4Connection of Wire Feeding Mechanism to Laser Processing Head ....................................18

5HMI........................................................................................................................................19

5.1 Home ..................................................................................................................................19

5.2 Setting.................................................................................................................................20

5.3 Process................................................................................................................................22

5.4 Monitoring..........................................................................................................................23

5.5 Function Switch ..................................................................................................................24

5.6 About..................................................................................................................................25

6Auxiliary Function .................................................................................................................25

6.1 Cut ......................................................................................................................................25

6.2 WeldSeam Clean.................................................................................................................29

6.3 Remote Clean .....................................................................................................................33

7Option Table of Welding Nozzle and Wire Feeding Nozzle...................................................36

8Troubleshooting Table...........................................................................................................37

9Reference Table of Welding Process.....................................................................................38