INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

SYDNEY |MELBOURNE | BRISBANE | PERTH | AUCKLAND

Australia 1300 788 778 www.rba.com.au | New Zealand 0800 722 111 www.rbagroup.co.nz

Has the product conguration sheet been submitted, if required?

Product Conguration Request:

Note: Default factory setting for the RBA1882-100 Series is as WELS 3 Star 6/3

ush volume at 300kPa inlet pressure. This product may be congured to suit water

supply pressures from 250 – 500kPa and WELS Star ratings of 3 Star and 4 Star to

suit comparable Watermark and WELS rated WC pans.

Please complete the following details for custom conguration of the

RBA1882-100 to suit site conditions and WC pan ush volume choice:

Customer Name: ………………………………………………………………………………

Customer Number: …………………………………………………………………………….

Delivery Address:

……………………………………………………………………………….

Project Name or Site Address of Installation:

……………………………………………………………………………..

…………………………………………………………………………………………………

Quantity of RBA1882-100 Required: ………………………………………………..

Water Supply Inlet Pressure on site: ………………………………………………….

WELS Rating Required to match WC pans: …………………………………………

I request that the RBA1882-100’s are congured for this project and to suit the site

information as stated above.

Name: ………………………………………………………………………………………

Email: ………………………………………………………………………………………

Mobile: ……………………………………………………………………………………

Signature

20

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

SYDNEY |MELBOURNE | BRISBANE | PERTH | AUCKLAND

Australia 1300 788 778 www.rba.com.au | New Zealand 0800 722 111 www.rbagroup.co.nz

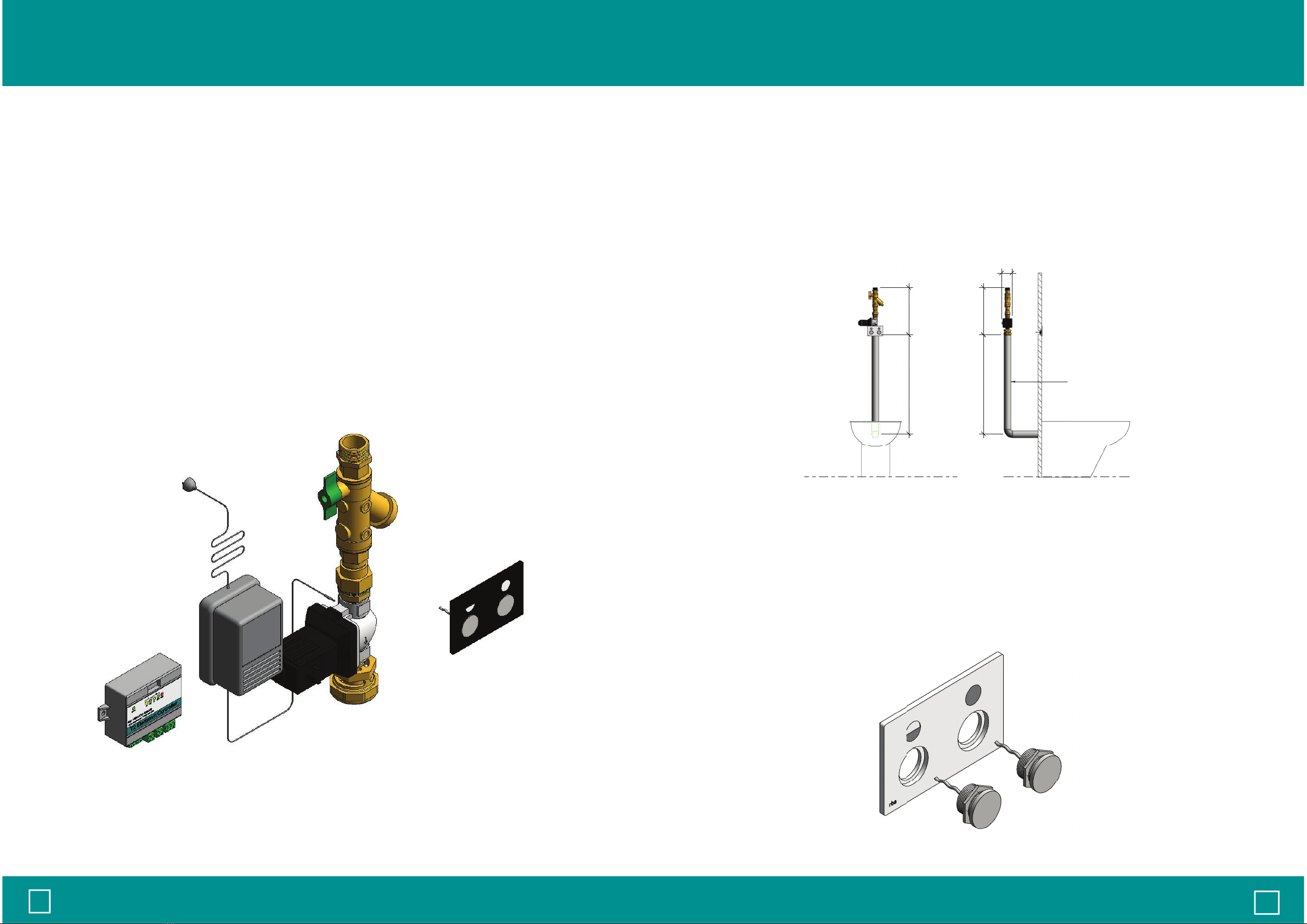

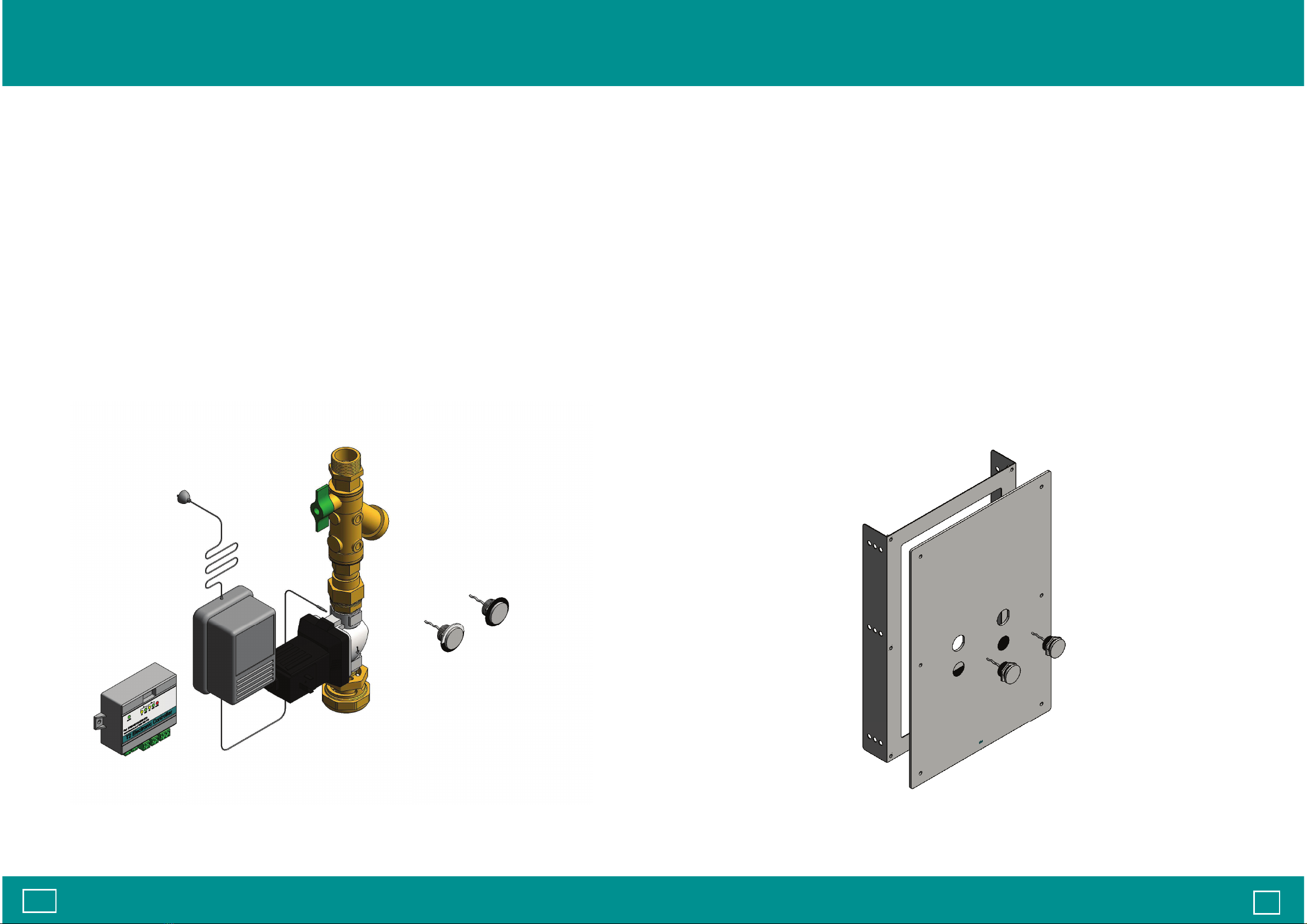

2.0 Components

RBA1882-100-001 Dual Flush Valve Incl Large Mounting Plate

5

1x RBA1882-100 'Nautilus' Flush Valve Assembly

1x RBA8012-999-003 T2 Controller [2019 version]

1x RBA8010-999-005 24V AC 2AMP Plug Pack Transformer

2x RBA8010-999-003 Piezo (3m tail)

1x RBA1880-999-001 Large Flush Valve Plate

1 x RBA1880-999-002 Recess Kit for Large Flush Valve Plate

6 x RBA1880-999-011 Counter Sink Screws (90° angle m4x25 (0.7) Pitch

Post Torx, Bit Tx15 H:3.1