Easy pan mounting to GOLIATH AND TITAN pans

Page 2 of 2

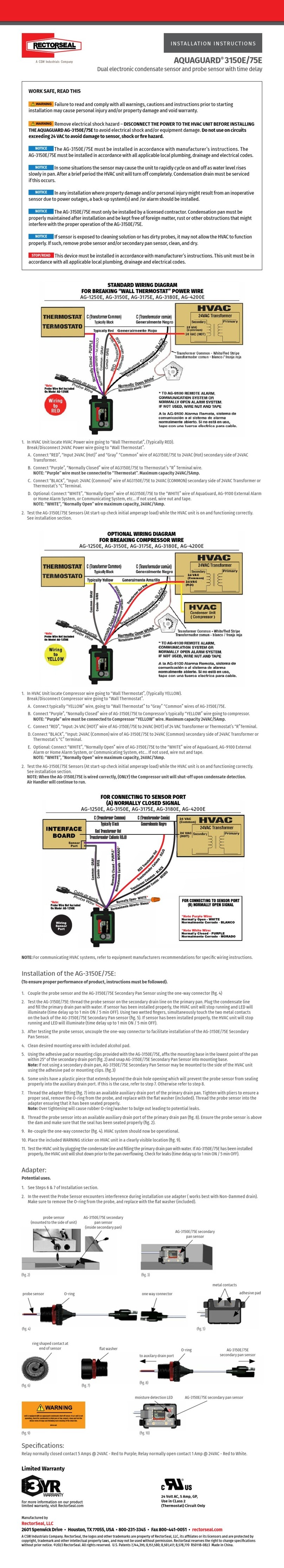

INSTALLATION INSTRUCTIONS AQUAGUARD® 42

00E

Water Sensor & Drain Port

Manufactured by

RectorSeal, LLC

2601 Spenwick Drive Houston, TX 77055, USA 800-231-3345 Fax 800-441-0051 rectorseal.com

A CSW Industrials Company. RectorSeal, the logos and other trademarks are property of RectorSeal, LLC, its affiliates or its licensors

and are protected by copyright, trademark and other intellectual property laws, and may not be used without permission. RectorSeal

reserves the right to change specifications without prior notice. ©2023 RectorSeal. All rights reserved. U.S. Patents 8,578,770; 8,317,169

R50118-0823 Made in China.

TITAN drain pan installation:

(To ensure proper performance of product, instructions must be followed).

1. Inspect the drain pan for any shipping damage that may have occurred. If cracked or broken,

DO NOT USE.

2. Make sure drain pan exceeds equipment dimensions by a minimum of 1.5" per side.

3. Make sure the pan-mounting surface is level and free of any debris.

4. For solid surface applications, place HVAC unit on blocks or 2-4x4 boards running the full length

of the Titan pan between the HVAC unit and the Titan pan on either of the water displacement

ridge. (g. 4)

5. For hanging application, place 2-4x4 boards running the full length of the Titan pan between the

HVAC unit and the pan on either side of the water displacement ridge. (g. 5)

Note: Pressure treated wood will not damage the pan.

6. Local code approved steel supports are to be placed 6" to 8" from the end of the 4x4 as shown.

(g. 5, 6)

IMPORTANT! When brazing, take precautions to prevent pan from coming in contact with torch heat

or brazing materials. It’s recommended that a damp cloth be placed under the lines being brazed.

(g. 4) (g. 5) (g. 6)

GOLIATH FURNACE horizontal drain pan installation:

(To ensure proper performance of product, instructions must be followed).

1. Refer to Furnace/Air handler instructions prior to installation.

2. Inspect the drain pan for any shipping damage that may have occurred. If cracked or broken,

DO NOT USE.

3. Make sure drain pan exceeds equipment dimensions by a minimum of 1.5" per side.

4. Make sure the pan-mounting surface is level and free of any debris.

5. Insert rubber Vibration Isolator (Goliath and Goliath Furnace series only) in the most appropriate

support receptacles (g. 7). It is not necessary to ll every receptacle.

6. Position air handler in the center of the pan. (g. 8)

7. For Goliath Furnace drain pan installations, refer to manufacturer’s instructions regarding

clearance specications.

8. For furnace installations, position the furnace with the heavy side of the unit resting on “back

side” of the pan, i.e. the side directly opposite of the sensor. (g. 7)

IMPORTANT! When brazing, take precautions to prevent pan from coming in contact with torch heat

or brazing materials. It’s recommended that a damp cloth be placed under the lines being brazed.

AquaGuard Goliath Furnace series drain pans are not designed for hanging

applications.

(g. 7)

oat switch

backside (opposite

of oat switch) vibration

isolators

(g. 8)

furnace

GOLIATH horizontal drain pan installation:

(To ensure proper performance of product, instructions must be followed).

1. Inspect the drain pan for any shipping damage that may have occurred. If cracked or broken,

DO NOT USE.

2. Make sure drain pan exceeds equipment dimensions by a minimum of 1.5" per side.

3. Make sure the pan-mounting surface is level and free of any debris.

4. Insert rubber Vibration Isolator (Goliath and Goliath Furnace series only) in the most appropriate

support receptacles (g. 9). It is not necessary to ll every receptacle.

5. Position air handler in the center of the pan. Safety hang or place pan on at level surface. Check

your local building codes before installation.

6. When hanging, pans must be supported equally at least 8" from each end by a support system

approved by local code. (g. 10)

IMPORTANT! When brazing, take precautions to prevent pan from coming in contact with

torch heat or brazing materials. It’s recommended that a damp cloth be placed under the

lines being brazed.

(g. 9) (g. 10)

GOLIATH FURNACE vertical drain pan installation:

(To ensure proper performance of product, instructions must be followed).

1. Inspect the drain pan for any shipping damage that may have occurred. If cracked or broken,

DO NOT USE.

2. Make sure drain pan exceeds equipment dimensions by a minimum of 1.5" per side.

3. Make sure the pan-mounting surface is level and free of any debris.

4. Insert one rubber Vibration Isolator at each strategic support location where the appliance

makes contact with the drain pan.

NOTE: It is not necessary to ll all the vibration isolator receptacles. (g. 11)

5. Position furnace in the center of the pan. (g. 12)

6. Refer to manufacturer’s instructions regarding “zero clearance” specications.

IMPORTANT! When brazing, take precautions to prevent pan from coming in contact with torch heat

or brazing materials. It’s recommended that a damp cloth be placed under the lines being brazed.

(g. 11)

vibration isolators

(g. 12)

furnace

NOTE: Must use

vibrationisolators

Specifications:

Relay normally closed contact 5 Amps @ 24VAC - Red to Purple; Relay normally open contact 1 Amp

@ 24VAC - Red to White.

Limited Warranty

For more information on our product limited warranty, visit RectorSeal.com

24 Volt AC, 5 Amp, GP, Use in CLass 2 (Thermostat) Circuit Only

5. Test sensor: Place sensor in secondary pan and add enough water to the pan to cover contacts

(approximately ¼"). LED will illuminate and HVAC unit will stop running if wired correctly.

rubber gasket thread nut

thread nut drain housing

drain housing

(g. 2) (g. 3)