Installation

Safety Precautions

1. Before operating the machine, read this Owner’s

Manual carefully. Learn the machine’s applications

and limitations.

2. Ground the machine properly. Be sure to follow

proper grounding and electrical procedures

described below.

3. Avoid extension cords. To minimize the risk of

tripping, improper electrical grounding, or over-

loading, extension cords are not recommended.

4. Use the proper power source. Refer to the

machine data plate. If the machine data plate has

been removed or is unreadable, call the RED DEVIL

EQUIPMENT Customer Service Department (see

the back cover of this Owner’s Manual) before con-

necting the mixer to a power source.

5. Avoid dangerous environments. Do not use the

machine in a damp or wet environment. Keep the

work area well lighted.

6. Keep the work area clean. Cluttered areas and

benches invite accidents. To prevent accidents,

be sure all electrical cords are out of the way.

Assembly

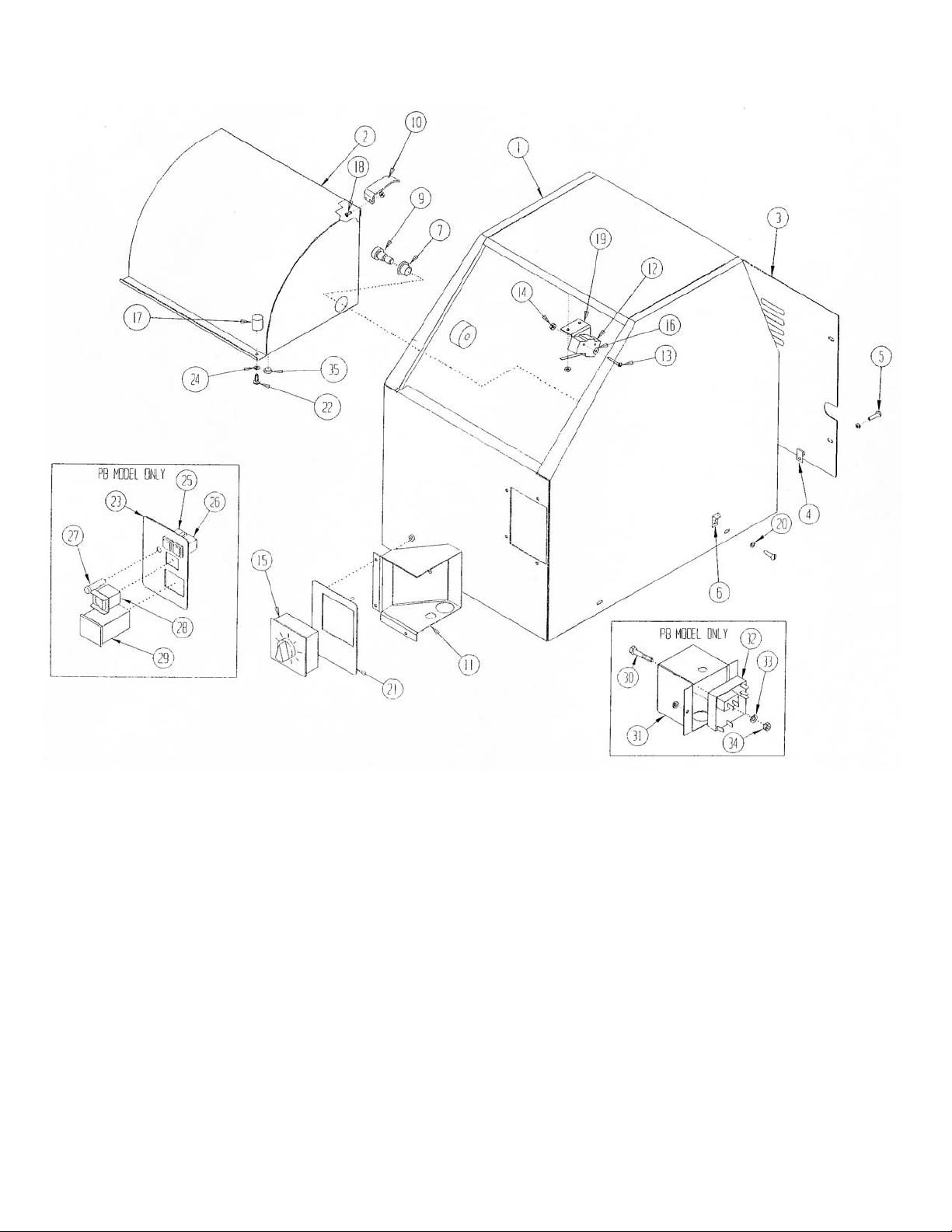

The Speed DemonSQ Mixer is shipped fully-assembled.

Remove the long shipping bolts that extend out of the bot-

tom of the mixer into the pallet. Unpack the machine and

set it on a firm and level surface.

IMPORTANT: Before Plugging in the machine or

attempting to operate it, remove all packing material.

Plug machine into an appropriate grounded receptacle

(see below).

The machine MUST BE GROUNDED. If there should be

an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric

current.

The machine’s power cord has a grounding wire with an

appropriate grounding plug. This plug must be inserted

into an electrical outlet that is properly installed and

grounded according to all local codes and ordinances.

If you must repair or replace the power cord or plug, do

not connect the grounding wire to either flat-blade termi-

nal. The wire with insulation having an outer surface that

is green (with or without yellow stripes) is the grounding

wire.

Check with a qualified electrician if you don’t completely

understand these grounding instructions, or if you are not

sure whether the machine is properly grounded. Do not

Electrical Connection and Grounding Requirements

modify the plug provided: if it won’t fit in the outlet, have

a proper outlet installed by a qualified electrician.

110V Units

Machines rated at 110V, 60 Hz are for use on a nominal

120V circuit. These machines have a grounding plug that

looks like the one shown in Fig. 2.

Extension Cords

Avoid using extension cords. If an extension cord is

unavoidable, consult a qualified electrician to determine

what type of extension cord will satisfy the grounding, cur-

rent capacity, and other requirements or the particular sit-

uation

Fig. 2: Grounding Plug of 110V Units

4

Risk of electric shock.

Always have machine

properly grounded.

Grounded

Outlet

Cover of

Grounded

Outlet Box

Grounding Pin