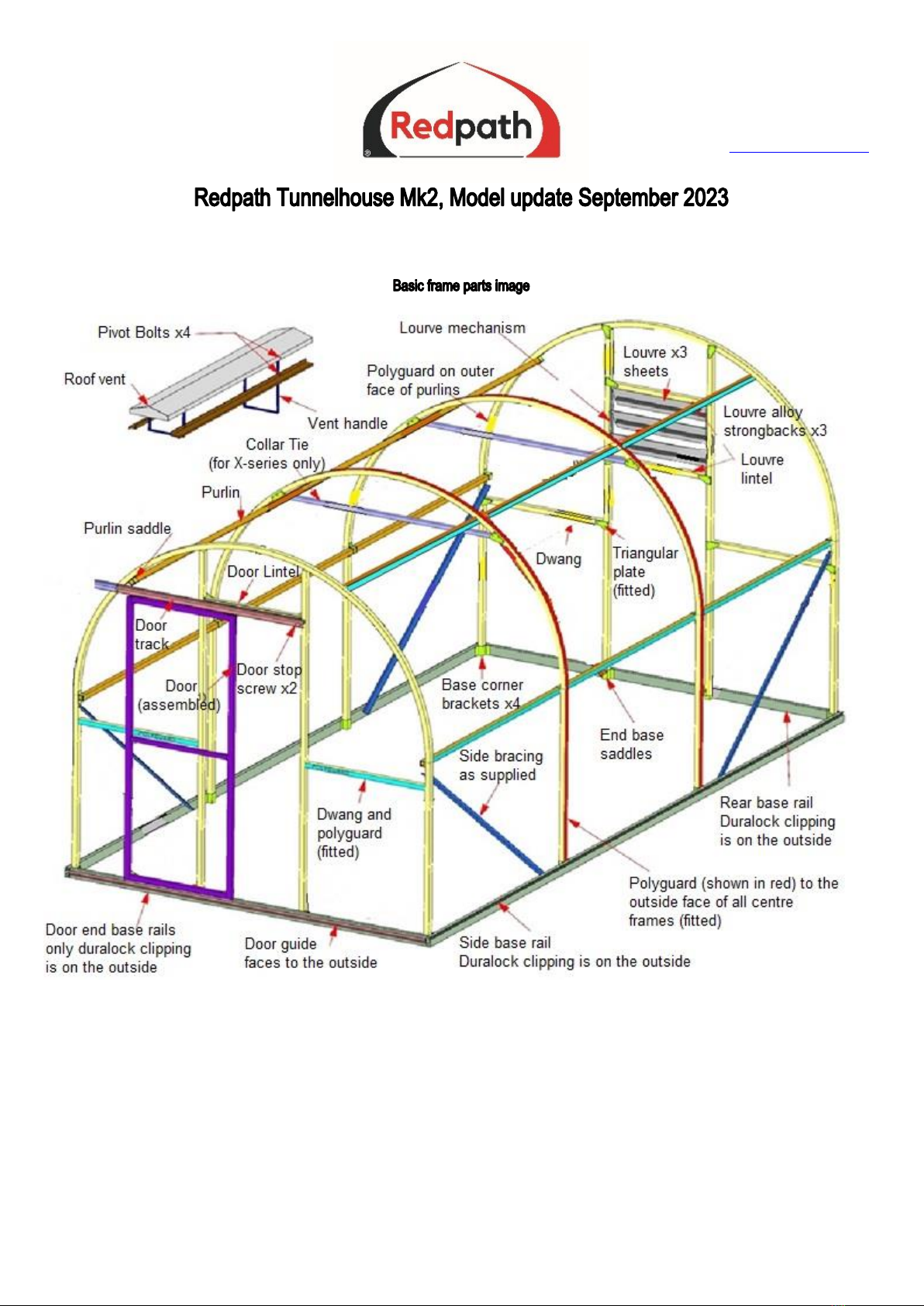

Effective from 31-Oct-23 Page | 10

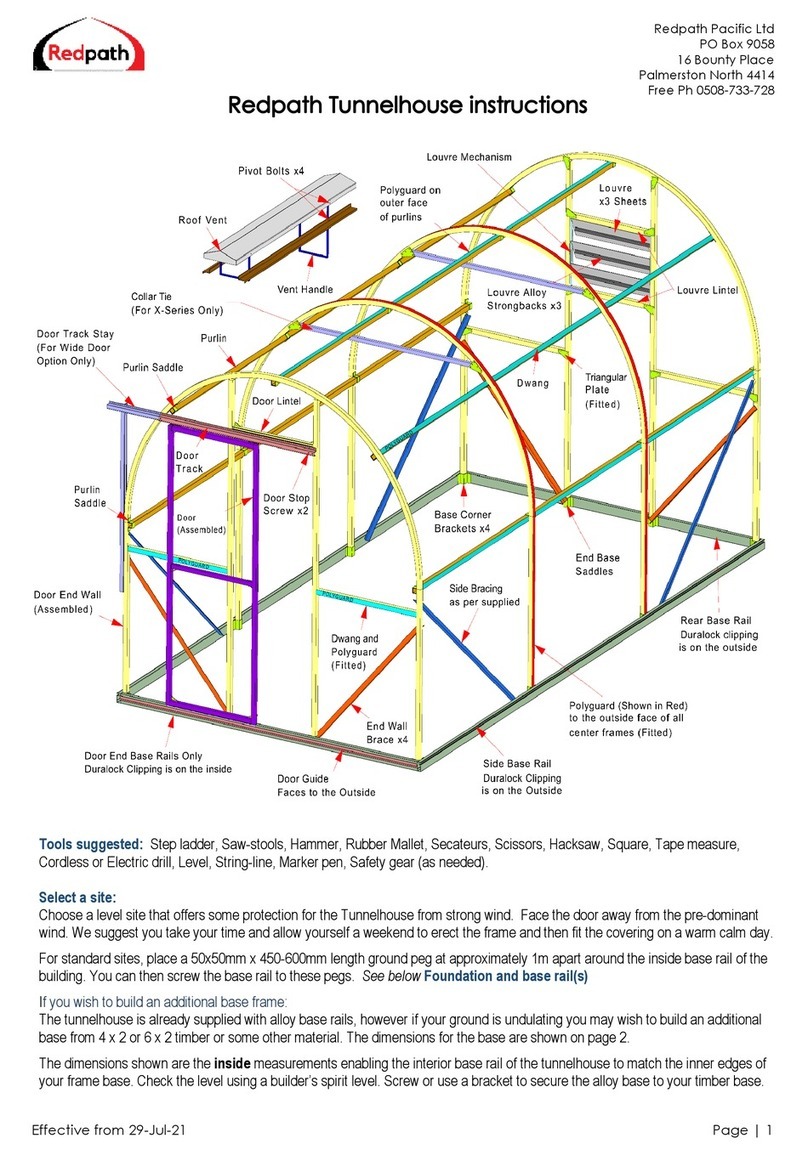

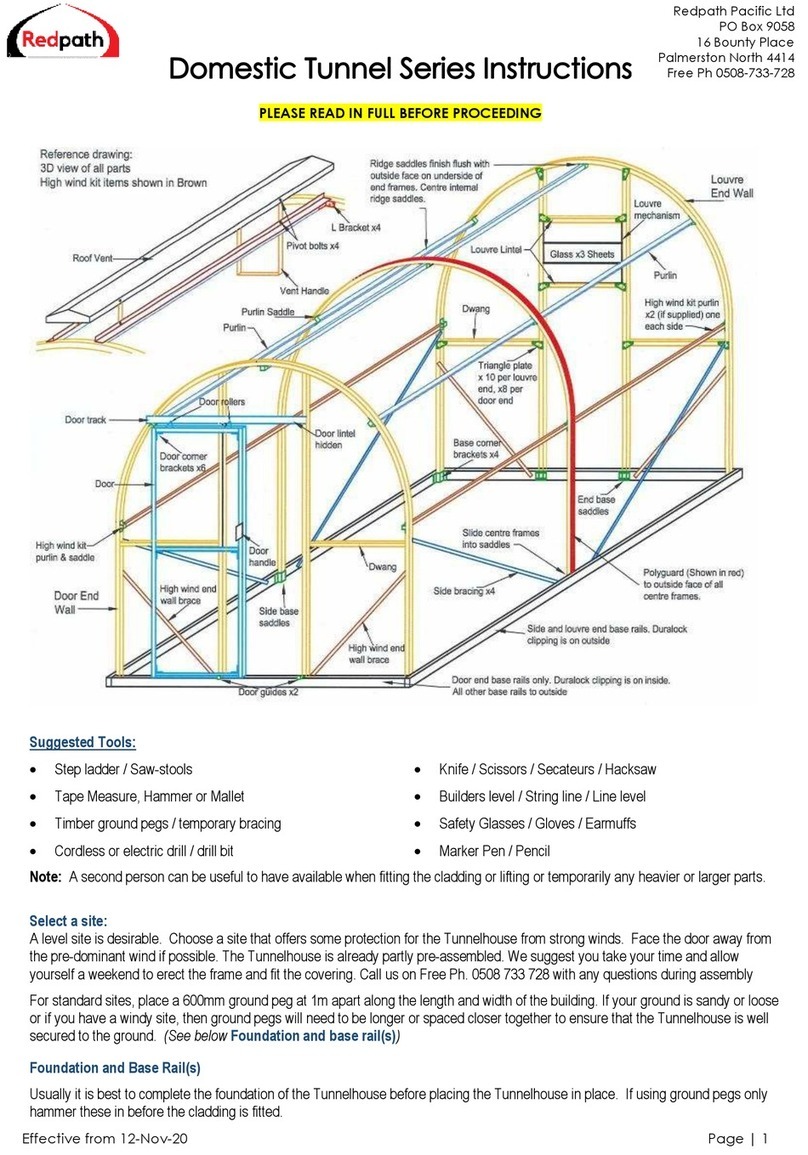

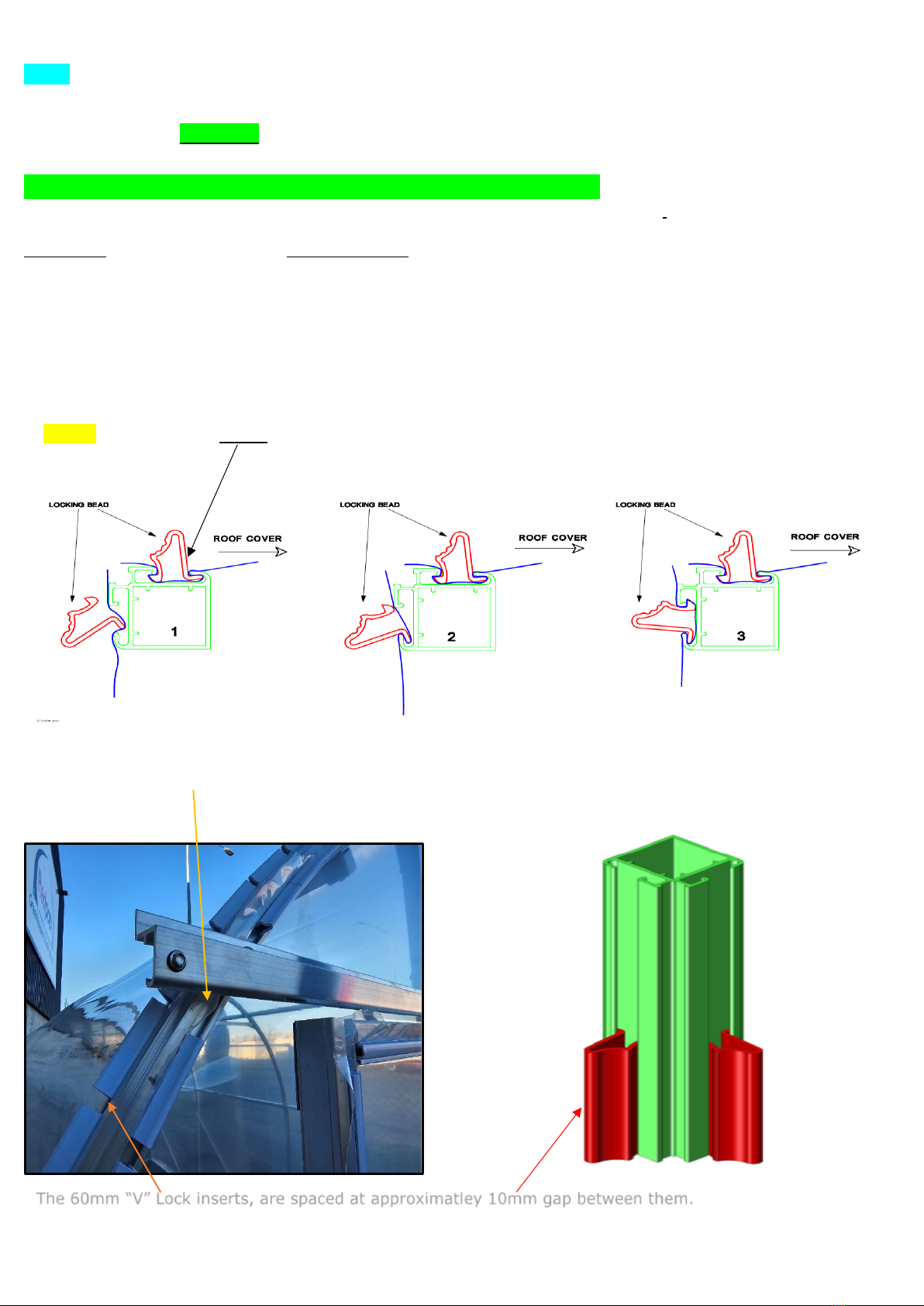

2. ROOF COVER, use the 60mm pieces of white “V Lock” on the end hoops only, See our YouTube channel “Mk2 Roof

covering videos steps 1 to 11 ”

If your Tunnelhouse includes a roof vent install the roof vent base before fitting roof covering (See step 4 on page 5, image V1)

NOTE: Take care not to damage the covering on the ends of the vent rails, Unfold the cover and lay it out over the Tunnelhouse so

that it rests in approximate position with an equal amount of excess film draping over each end hoop and to each side base rail.

As per the YouTube videos begin at the apex at one end of the Tunnelhouse and install two pieces of 60mm V lock insert in the

direction as shown above (do not put in backwards!) , Then position a piece to your left and right where the curvature of the end stops

and the sidewall begins (9 o’clock and 3 o’clock positions)

Move to the opposite end, pull the cover tight along its length and repeat the step above.

If satisfied with the cover flatness and tension, begin to fill in the gaps in-between the inserts already fitted. If not satisfied with the

tension, un-clip the V Lock re-tension the cover and re-fit the V lock

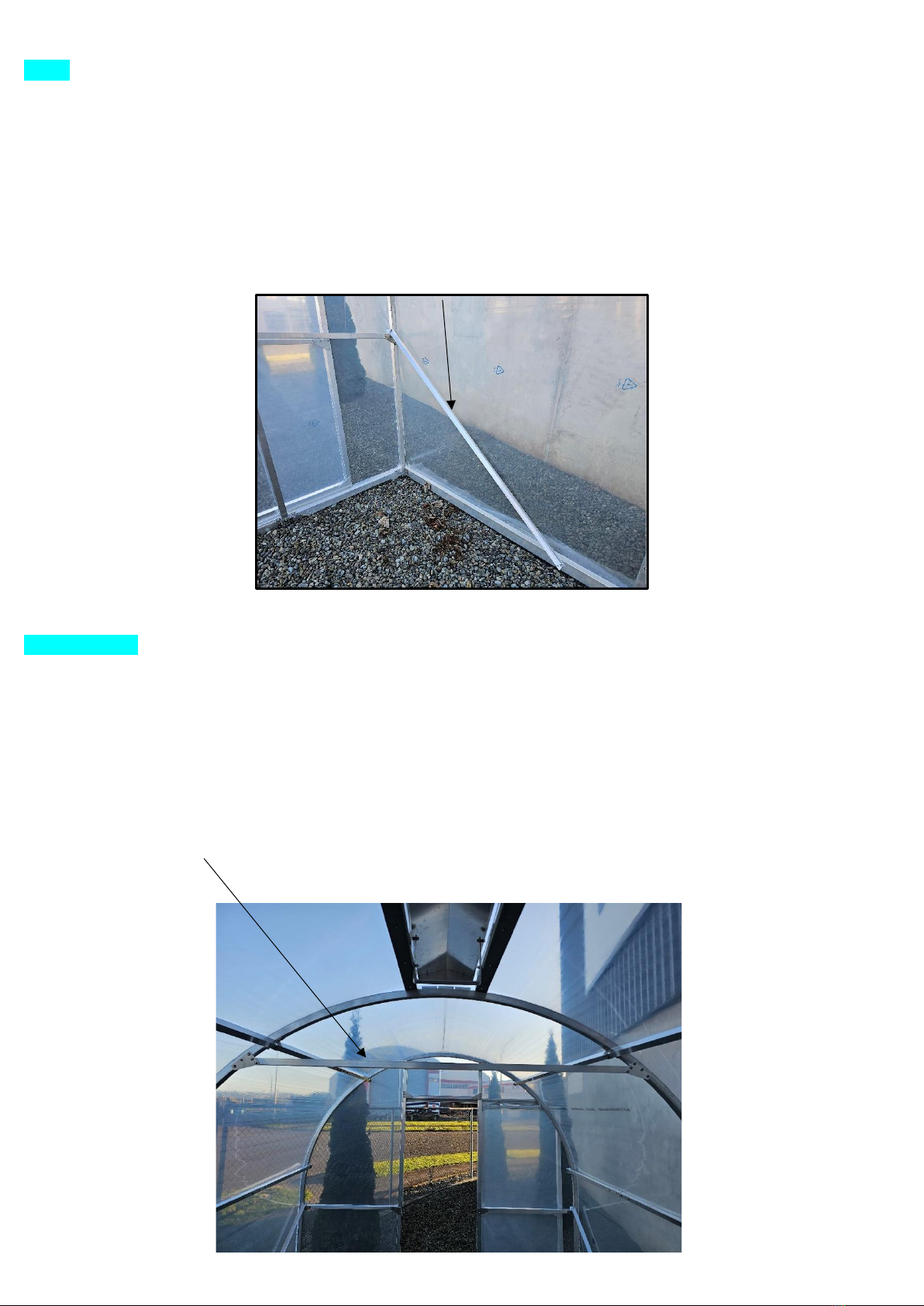

Now move to the side base rails. The side base rails use the Duralock clipping system (see assembly order page 10, and see

YouTube videos)

TIP: When fitting the side base rail clipping its sometimes simpler to lift the entire side of the Tunnelhouse up in the air and rest it on

blocks or saw stools –this can make it more convenient to insert the sidewall base rail Duralock clip.

Begin at the center of the base rail & start inserting the U shaped Duralock channel insert + bead whilst tensioning the cover as

much as possible. Work your way to the left and right toward the ends of the building. (See image on Page 10 above)

3. END WALLS:

You will fit the 3m x 3m end walls cover in one piece (see video)

Use the 60mm V shaped Lockstrip insert for the front face wall of the end hoops See image L4 page 8

Like the roof ends - Start at the apex and position a 60mm piece. Then position a piece to your left and right where the curvature of

the end stops and the sidewall begins (9 o’clock and 3 o’clock positions)

Then pull the cover flat and position another 60mm piece of Lockstrip midway in-between these two.

If satisfied with the cover flatness and tension, begin to fill in the gaps in-between these inserts and also the rest of the end wall edges

and base rail parts.

NOTE: At the door end the base rail Duralock groove is on the INSIDE of the tunnelhouse, - this is so that there is sufficient

clearance between the end wall covering and the sliding door.

Note: When you come to fitting the door track remove one or two pieces of the 60mm V Lock on the front face of the end hoop where

the door tack will be attached to the hoop, so that the track sits flush on the hoop face. See image L4 Page 8

Create the opening for the door or louvre end wall cladding. Use a knife or scissors & cut an “X” shape by cutting diagonally from corner to

corner where the door or louvre are to be positioned. You can then place the Duralock clipping around the perimeter edge of the door and

louvre openings using the Duralock clips. Stop the clip system approximately 25mm short of any corner.

Step 8: ROOF VENT CAP: If an option on your tunnelhouse.

The roof vent base has already been fitted in Step 4.

After the main roof and sidewall covering has been fitted, - you can re-fit the cap vent See our roof vent videos on YouTube

1. Create the opening for the vent in the roof cladding where the vent will be placed (between the vent base rails). Use a knife or

scissors & cut an “X” shape by cutting diagonally from corner to corner between the steel vent rails See image V4 below

2. The Duralock2 clip system is used along each of the 1.5m steel vent rail See image V2 & V4 below

3. Insert 3 pieces of the 60mm V Lock at the apex of the hoops at both ends of vent See image V2 & V4 below

4. Secure the tail of the cover on top of the steel upstand using the white Omega clips See image V2 / V4 below

5. Trim off the excess film behind the Omega clip to 25mm and also at the end of the roof vent

6. Install the roof cap using the 6mm bolts, spacers and nuts supplied See image V3 below and Youtube video.

Test the roof vent for open / close action and adjust tension on pivot bolts if needed.

For Auto opener vent option see V5 below