HELPFUL HINTS

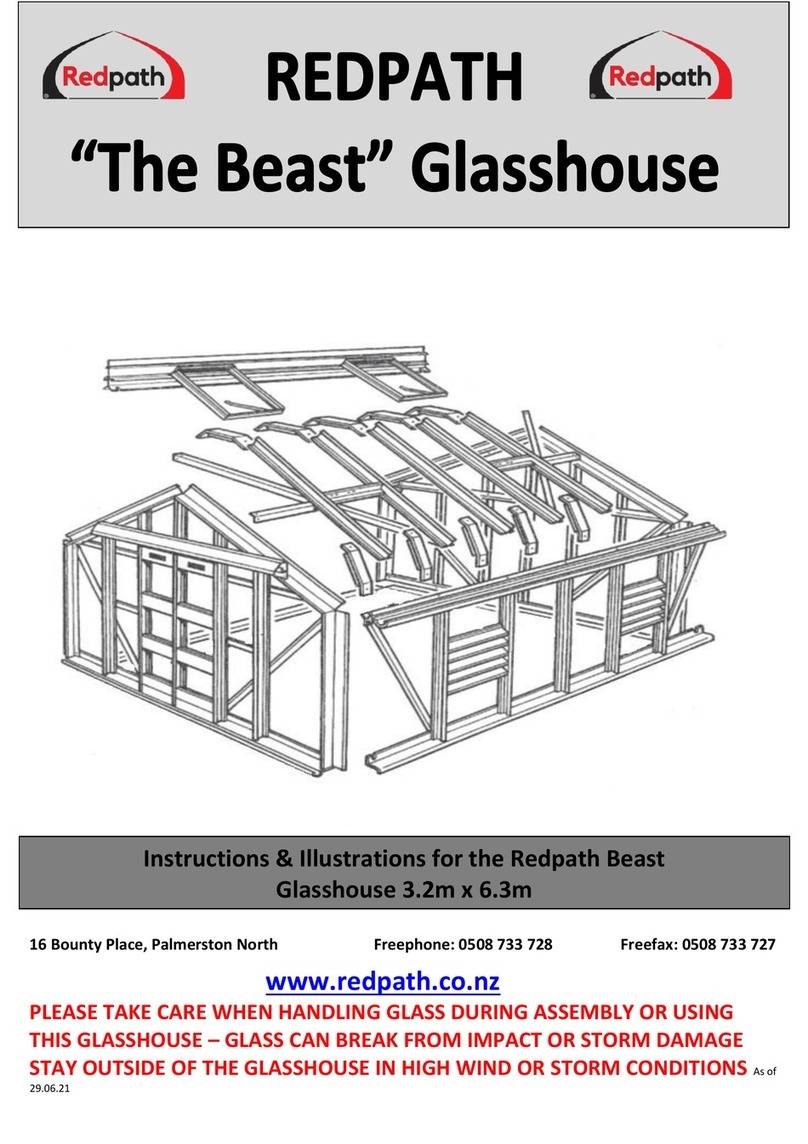

Please do take your time and be sure to READ ALL INSTRUCTIONS carefully before assembling.

Do not assemble frame in high winds.

The greenhouse frame should be anchored to a permanent foundation. This will not only help secure it against

powerful winds, but will help prevent breakage of the Polycarb by the freezing and thawing process of the earth.

Locate the Polycarbhouse in a sheltered or semi-sheltered position. Polycarb is a fragile product and strong winds, or

flying debris could potentially damage the Polycarb sheeting. Secure the roof vents in a closed position, close doors &

windows if very windy. A shelter belt should be considered to protect the Polycarbhouse and plants within in windy

locations.

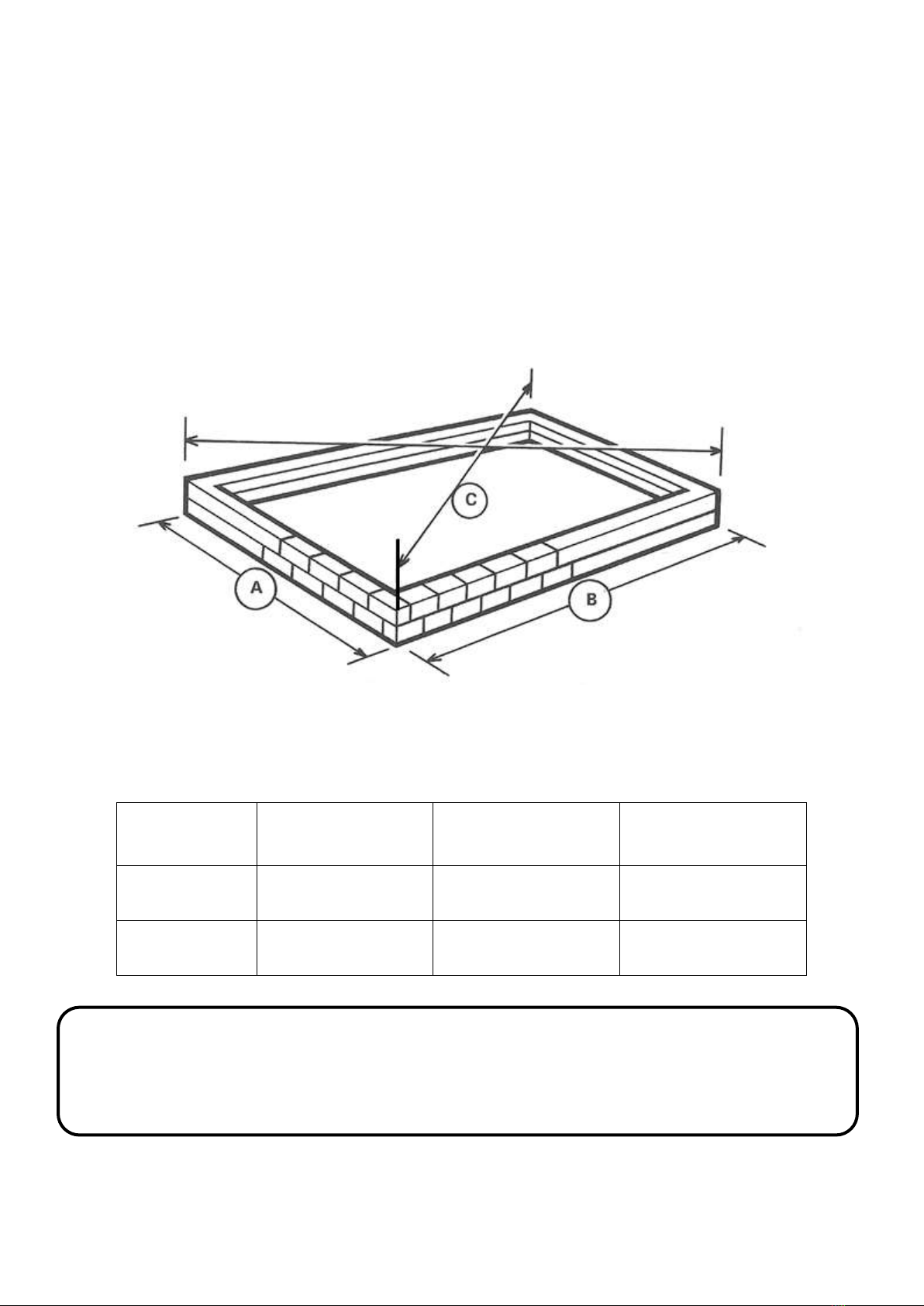

When building your own brick/concrete foundations ensure that they are level and square otherwise your frame will

not be correct and the Polycarb will not fit.

Be sure all four corners of the constructed greenhouse are square before installing Polycarb, and do not install the

Polycarb till the greenhouse is on a permanent foundation.

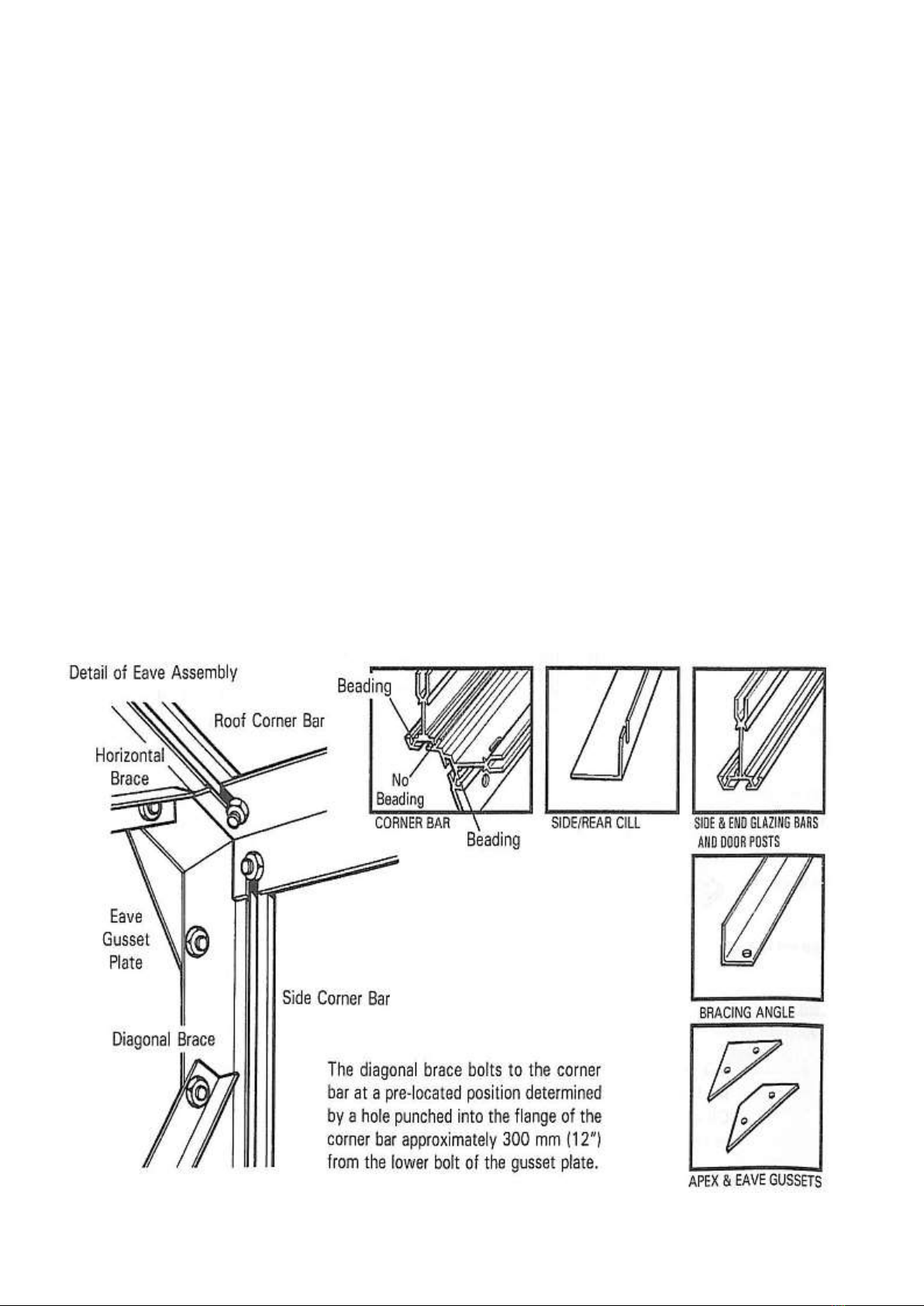

When inserting the neoprene beading, wetting the rubber or frame with mild soapy water will ease its installation.

Do not place your greenhouse in vulnerable locations such as under trees, playing areas etc.

Children should not play near Polycarb greenhouses. Do not occupy the Polycarbhouse in times of high wind or poor

weather (hail etc)

REMEMBER: Polycarb is fragile, handle with care!. Beware that flying Polycarb from strong wind can/will travel some

distance and can be a dangerous hazard for property and persons surrounding the Polycarbhouse

Gloves should be worn. Protective eyePolycarbes should be worn.

If your greenhouse is a painted one, there are a few 1/8” holes in the ends of some bars. These are jig holes for powder

coating and have no bearing on construction. (Key point).

WHEN CONSTRUCTING A PAINTED MODEL PLEASE TAKE CARE NOT TO DAMAGE THE FINISH BY WORKING ON

CONCRETE OR PATIOS.

Remember to fit the silver aluminium tape to the top edges of the polycarbonate sheeting before fitting them to the

greenhouse

Fit the 20mm square strongbacks (include a 75mm piece of the 20mm x 3mm white double sided tape at each end)

after installing the polycarbonate sheeting.

INSTALLATION INSTRUCTIONS 1.92m MODEL RANGE

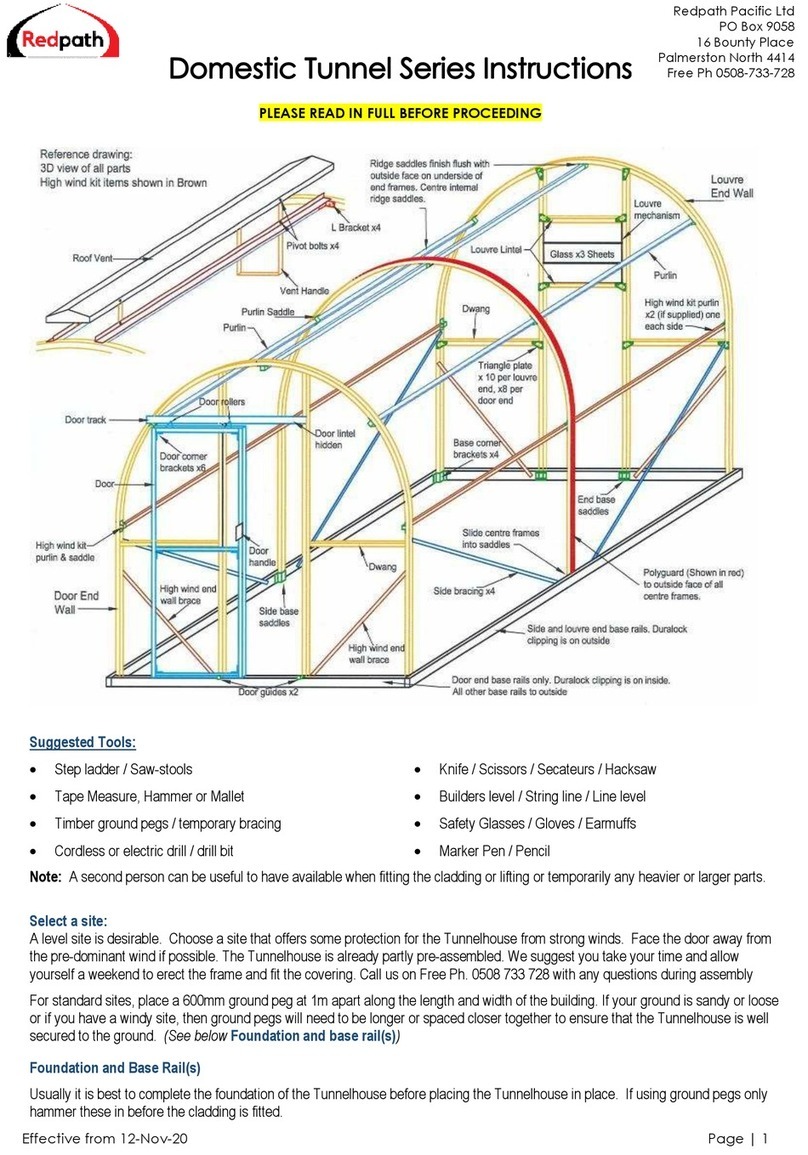

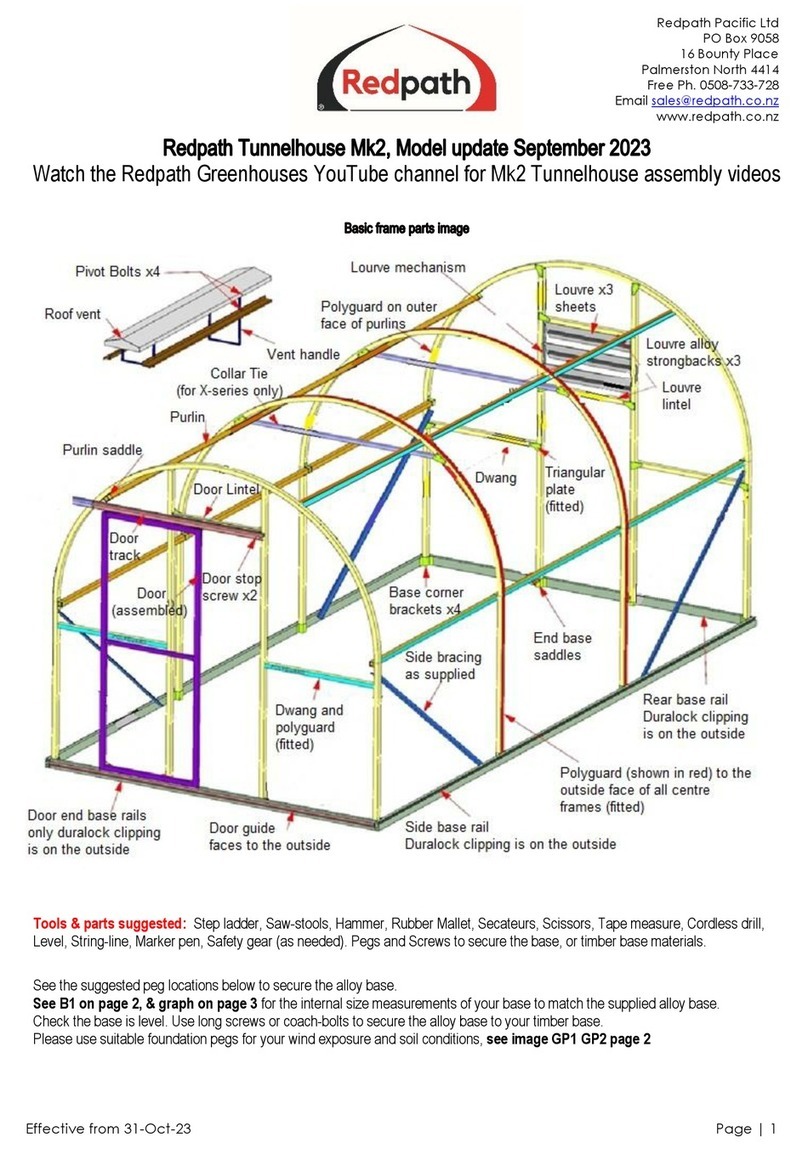

The contents of this carton are divided into the different frame assemblies that collectively make up the completed

greenhouse framework.

It is recommended that each frame assembly is fully completed moving on to the next.

The contents are as follows:

1) Two side frames.

2) Rear end frame.

3) Door end frame.

4) Roof Vent.

5) Door.

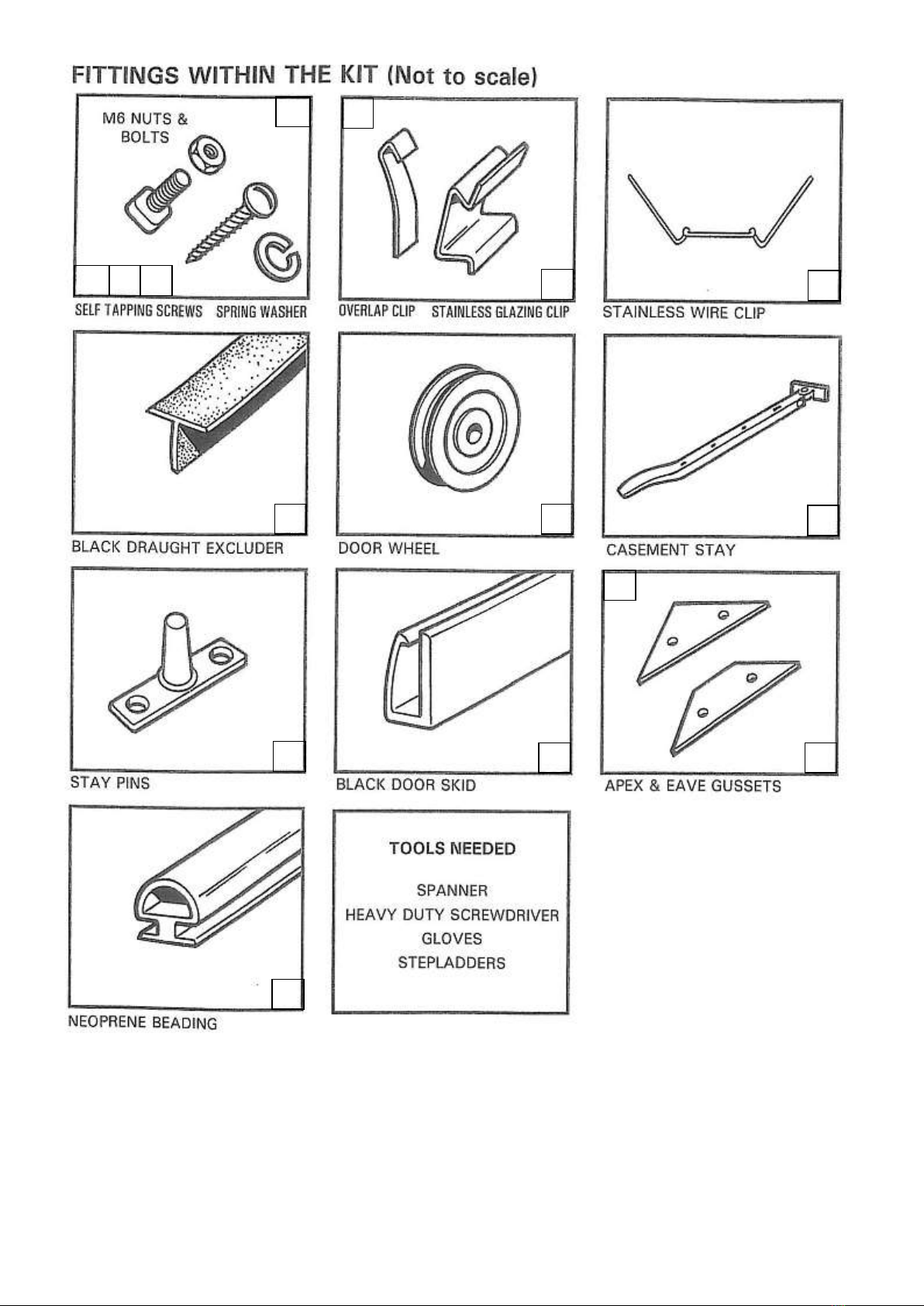

6) Bag of Fittings containing:

a. Nuts & bolts for general assembly.

b. Overlap clips not used for Polycarb.

c. Spring clips not used for Polycarb, wire clips are supplied

d. Casement stay

e. Casement stay nuts and bolts.

f. Four eave plates (not in the main bag but taped up with the casement stay).

g. Two ridge plates.

h. Two door wheels.

i. Two door guides.

j. Small self-tapping screws.

k. 1 Large self-tapping screw.

l. 1 Spring washer

m. 1 Door catch.

7) Roof bars.

8) Coil of glazing beading

9) One length of ridge

10) Two black rubber draught excluders.