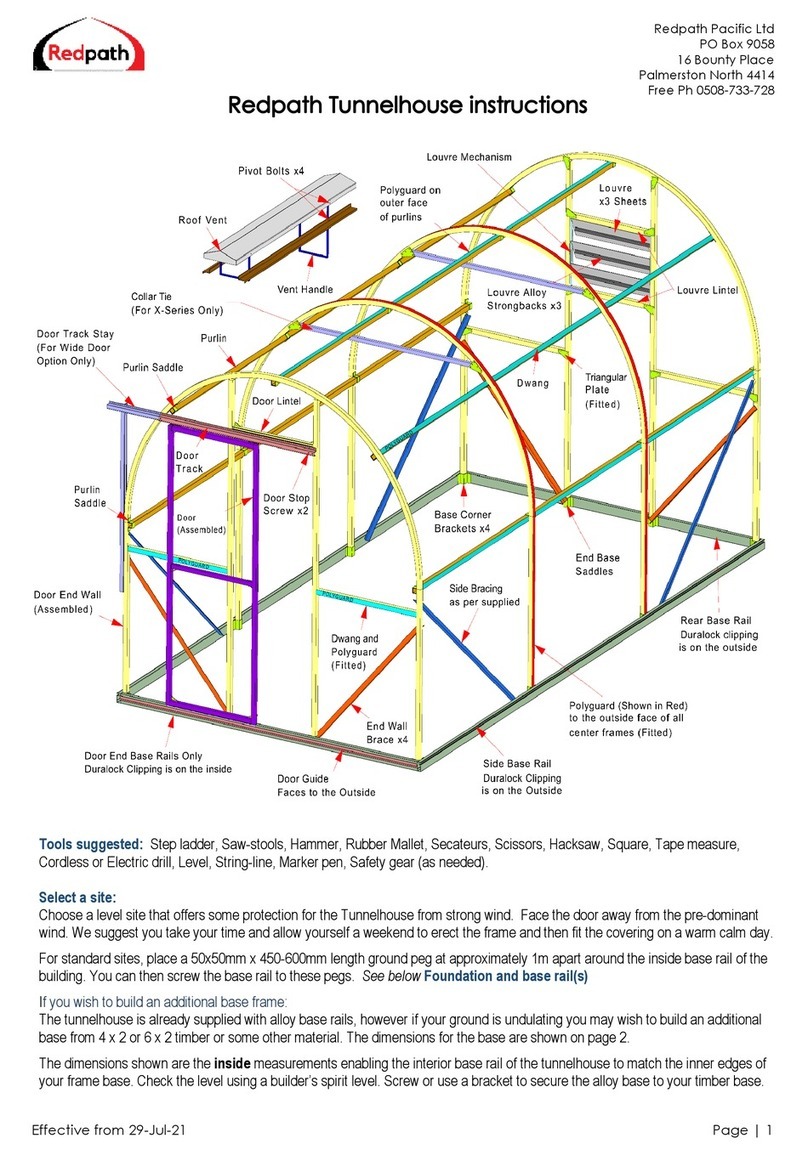

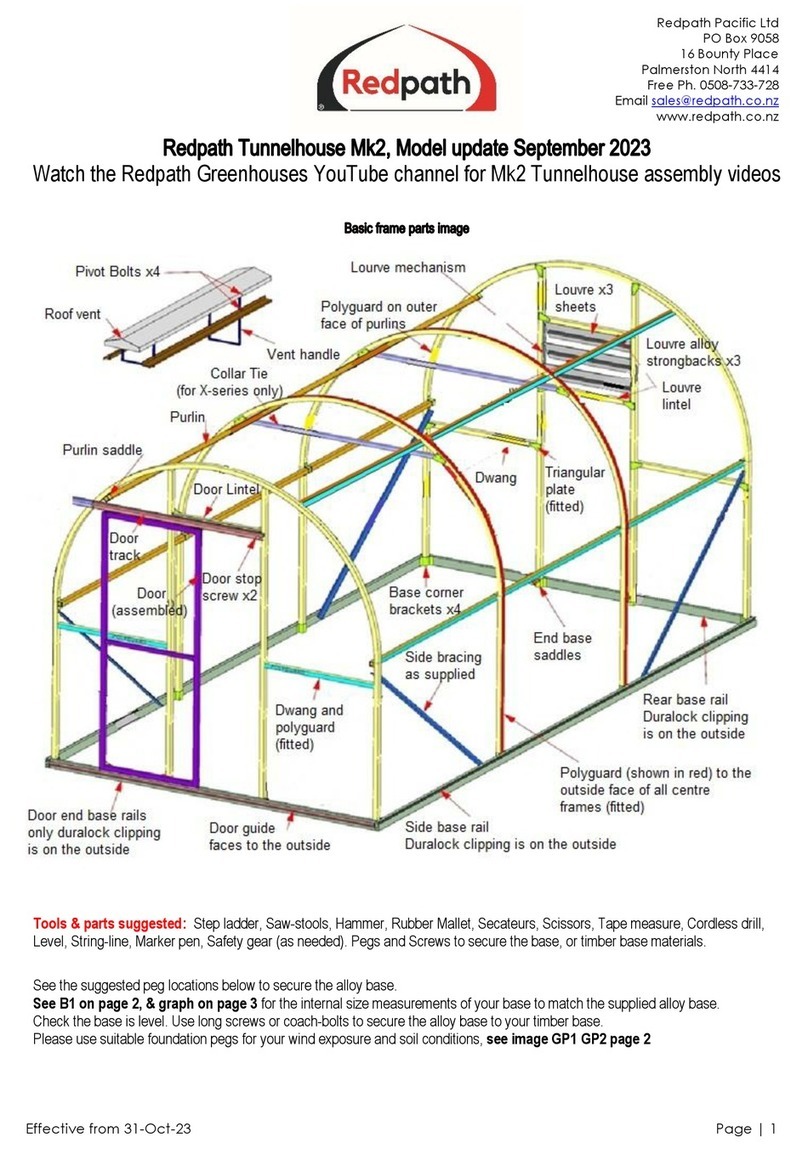

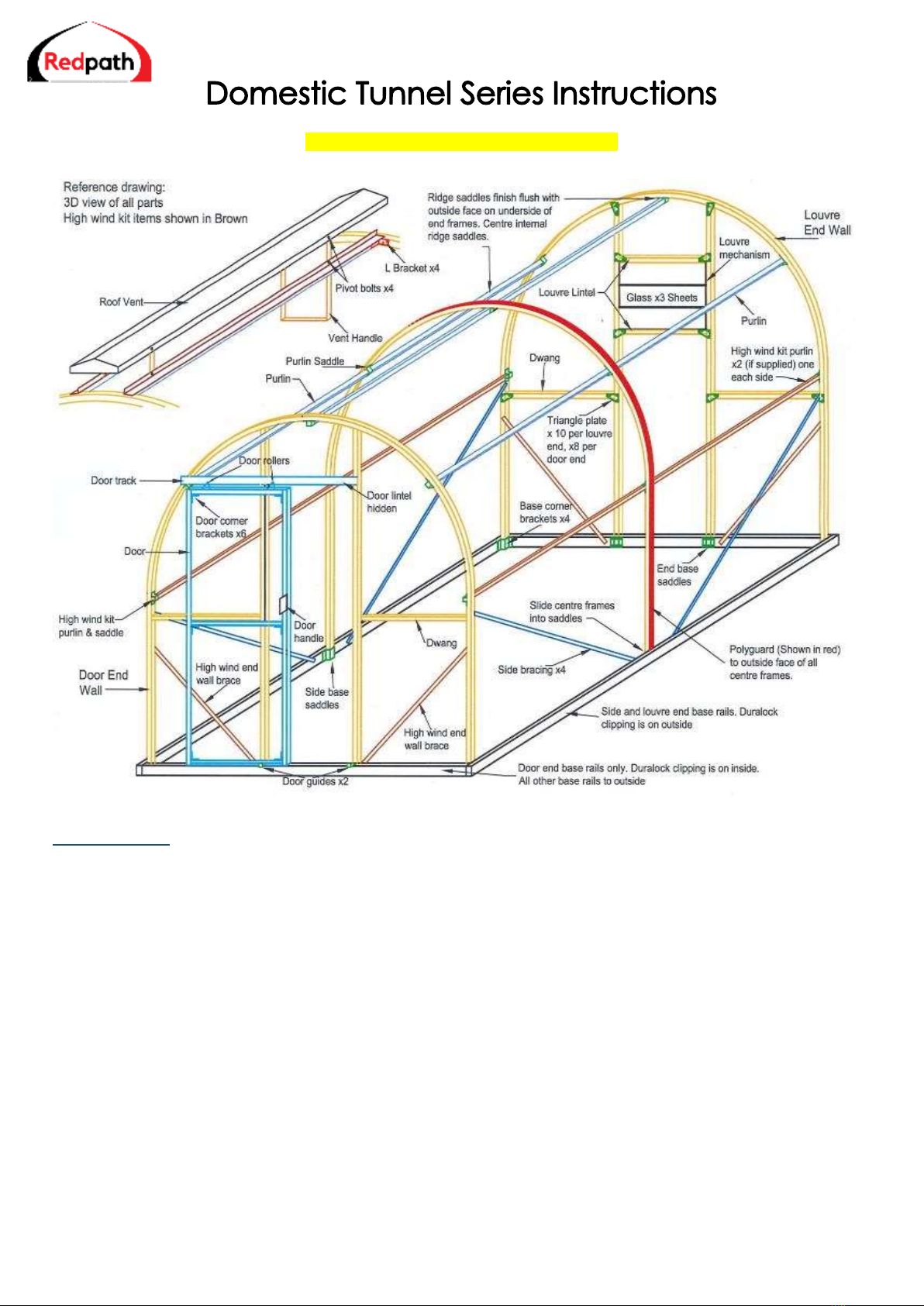

FITTING THE COVERS TO THE TUNNELHOUSE

There are four pieces of covering supplied for this building: The roof and sidepiece is one part (largest), there are two x end

pieces (3m x 3m), and one x door piece (1m x 2m). The Polyshade models will have shadecloth on the end walls and door, The

shadehouse models will have shadecloth on all surfaces.

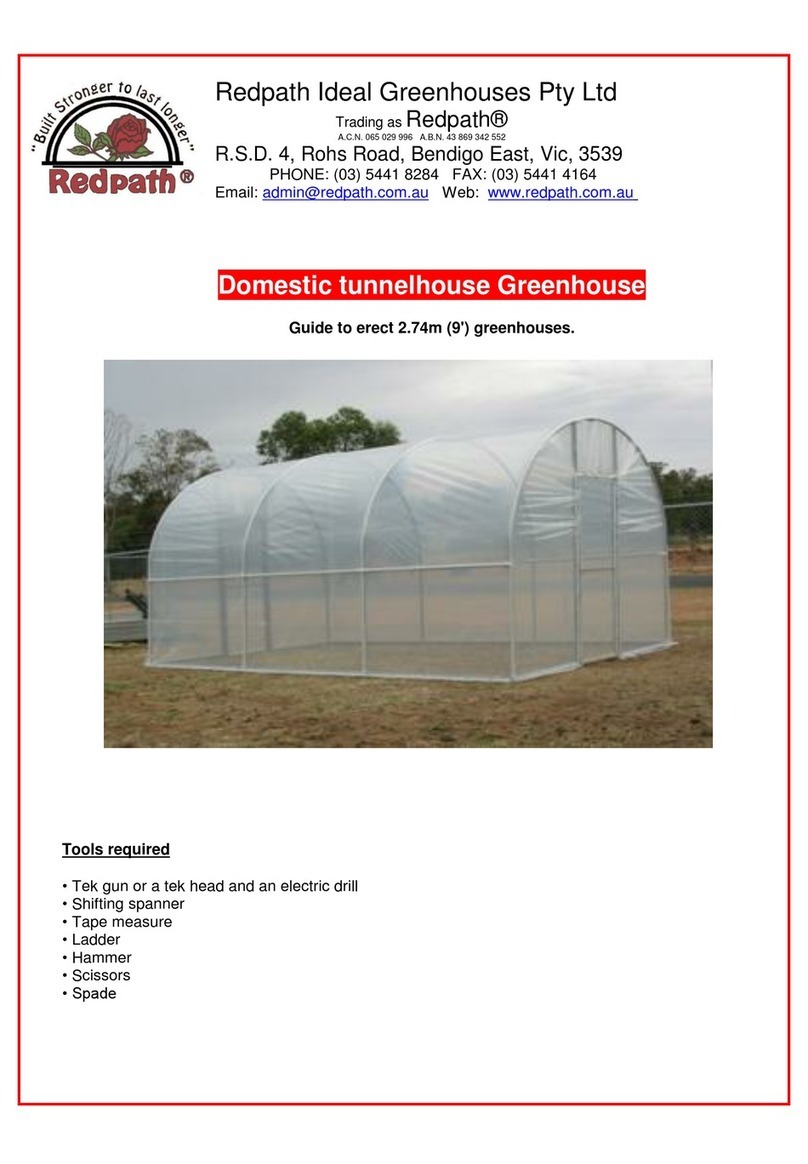

Install the clear covering on a warm, calm day, (this makes the work and the tensioning of the covering easier).

Note: When fitting the clear roof part cover it should have the printing on the cover facing to the inside.

DOOR COVER –use the Duralock holding system

Lay the door frame on the ground with Duralock groove facing upward and place the 2m x 1m door cover in approximate position

You will need to cut the Duralock inserts with a pair of secateurs to suit the length of the frame work. The Duralock insert will stop

short approximately 25mm from each end.

You will begin by fitting the Duralock insert to the top door rail firstly, - then the bottom door rail (pulling the cover tight as you do

so). Then install the inserts to the two longer side door edges. (begin in the middle and work toward the corners) see (Pic page

8)

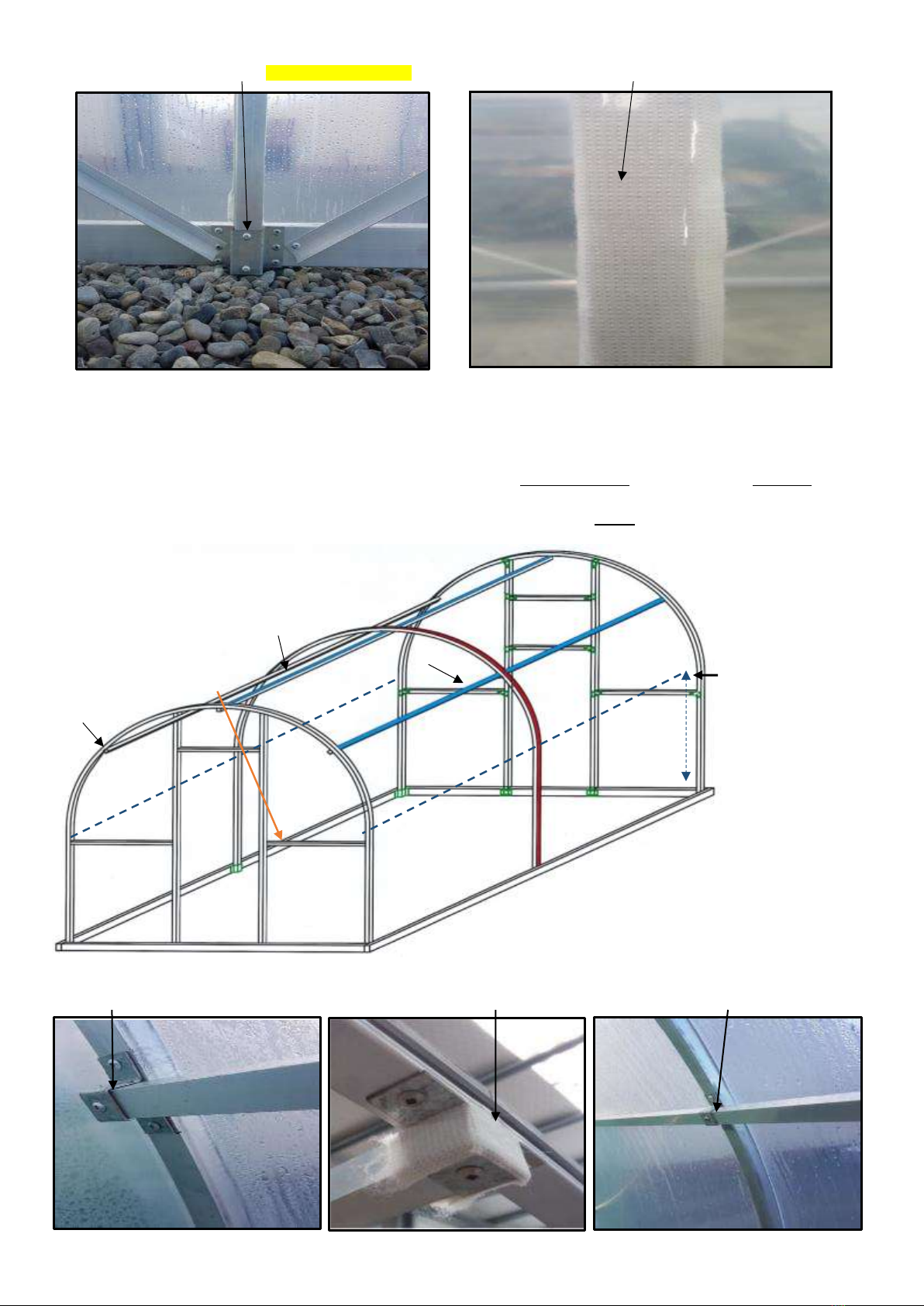

Locate the channel shaped insert strip fully as above then tap in the ‘bead’part with a rubber mallet

ROOF AND SIDEWALL COVER, use the Lockstrip holding system for the end hoop parts and Duralock 2 holding system

is used for the side base rails

The roof and sidewall cover is supplied in one piece. The width is 6m and the length will suit the size of the Tunnelhouse that you

have ordered.

If your Tunnelhouse includes a roof vent please install the roof vent kit before-hand (see instruction below), You will need to cut

and remove the ridge purlin when you choose to locate the roof vent.

Before fitting the roof cover remove the cap vent part plus the aluminium pivot arms and handle see (Pic V2) above

(leaving the two vent rails and upstand in place (See Pic V1 below)

TIP: You can place a temporary rope or strap along the full length of the Tunnelhouse 750mm each side of the ridge on top of the

hoops, to help support the roof cover whilst you distribute it across the Tunnelhouse. The rope helps to stop the covering from

draping down between the hoops, and assists with you placing tension on the cover.

NOTE: If your Tunnelhouse has a roof vent take care not to catch the cover on the vent rail upstands see (Pic V1) above when

laying it out into position.

NOTE: The print name on the cover should face to the inside of the Tunnelhouse so that the text reads correctly (left to right)

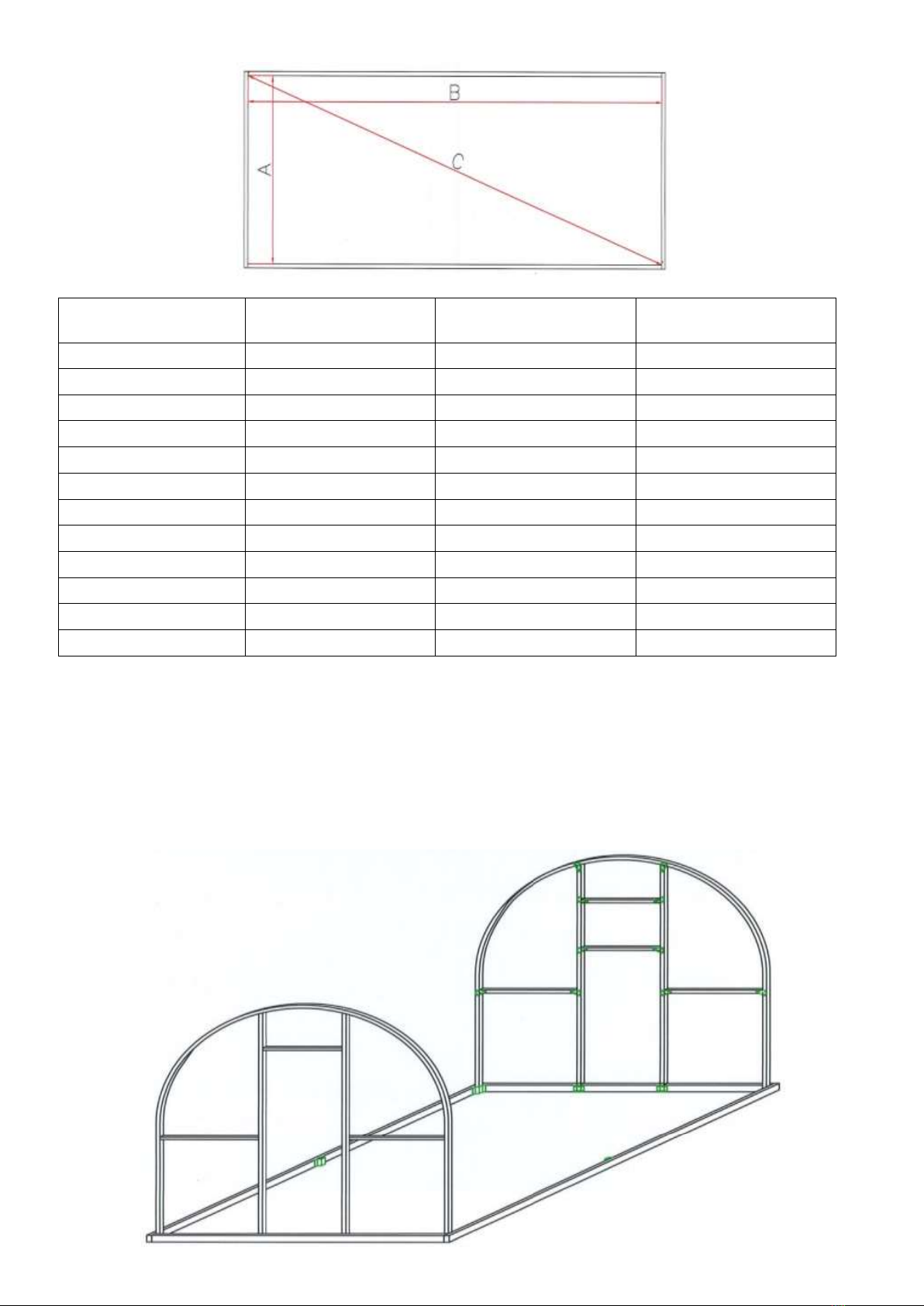

Reminder : As mentioned in stage 2 (page 5) do not fit the two screws in the base rail saddles that hold the internal hoops in

place, with these two screws not in place the hoops will sit down a little lower, and they can then be raised back up into place

after the covering has been fitted which will add tension to the covering

Unfold the cover and lay it out over the Tunnelhouse so that it rests in approximate position with an equal amount of excess film

draping over each end hoop and each side base rail.

Begin at one end of the Tunnelhouse and install the Lockstrip holding system starting at the apex and working to the left and right

down each side of the end hoop. See the lockstrip video on the website.

Go to the other end and pull the cover tight along the length of the ridge. Install the Lockstrip holding system starting at the apex

and whilst pulling the cover as tight as possible –work your way to the left and right installing the Lockstrip holding system down

each side of the end hoop.

Now move to the side base rails. These use Duralock 2 clipping system.

TIP: Read the Duralock 2 clipping system in these instructions and also see this link for an assembly video

http://www.redpath.co.nz/commercial-greenhouse-accessories/greenhouse-film-clipping-systems.html

Begin at the center & start inserting the U shaped Duralock channel insert + bead whilst tensioning the cover as much as

possible. Work your way to the left and right toward the ends of the building.

TIP: Sometimes it is simpler to lift the entire side of the Tunnelhouse up in the air and rest it on blocks or sawstools –as this can

make it more convenient to insert the Duralock clip.