6

HELPFUL HINTS & ADVICE

Please take your time and be sure to read all instructions carefully before assembling. The Polycarbhouse structure does often

require at minimum an “experienced DIY” type person or a semi-skilled builder to assemble.

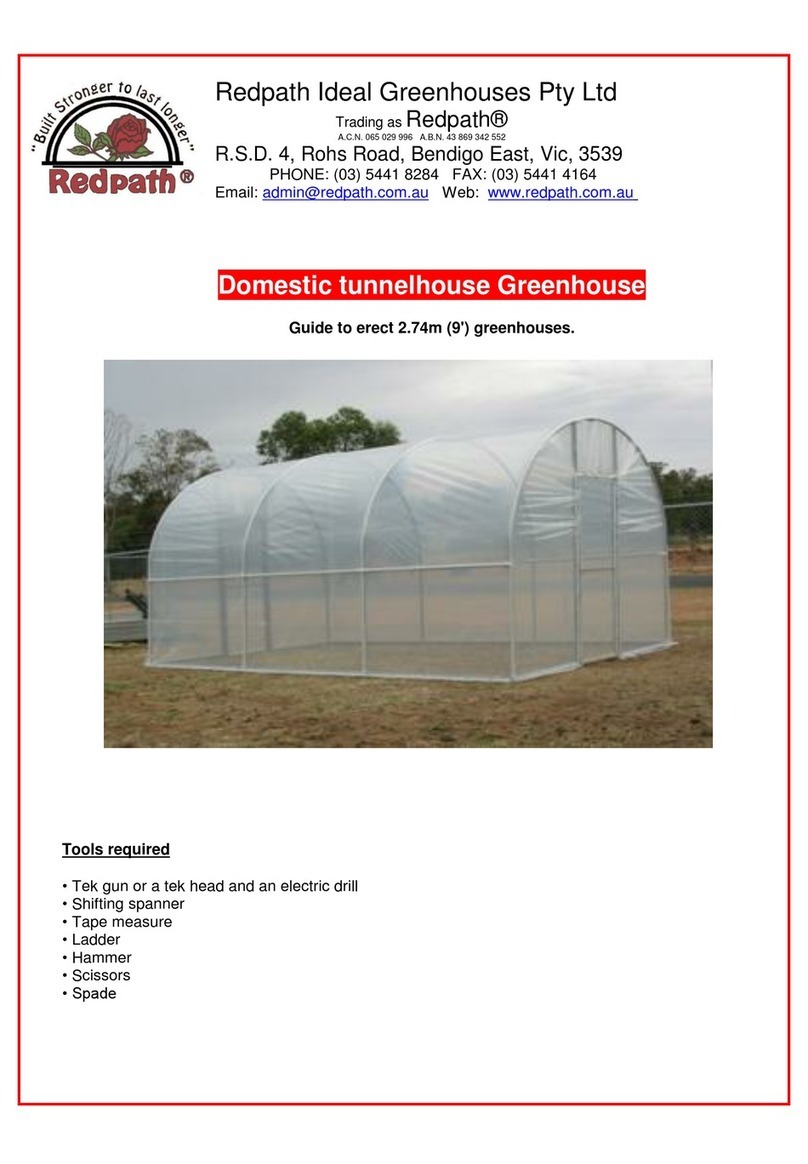

Locate the Polycarbhouse in a sheltered or semi-sheltered position. PolyCarb is a fragile product and strong winds, or flying

debris could potentially damage the PolyCarb sheeting. Secure the roof vents in a closed position, close doors & windows if very

windy. A shelter belt should be considered to protect the Polycarbhouse and plants within in windy locations.

Do not assemble the frame or attempt to glaze in windy, or damp conditions

The Polycarbhouse frame must be anchored to a permanent foundation / base. This will not only help secure it against strong

winds, but will help prevent breakage of the PolyCarb via ground movement. Materials for the base are optional & are not

supplied as part of this kitset.

When building your own timber/brick/concrete foundations/base ensure that they are level and square and built to the correct

outside measurements otherwise your frame will not be correct and the PolyCarb will not fit.

Be sure all four corners of the constructed Polycarbhouse are square before installing any PolyCarb, and do not install the

PolyCarb until the Polycarbhouse is secured onto a permanent foundation/base.

Do not place your Polycarbhouse in vulnerable locations such as under trees, near children’s playing areas, upon loose soils, in

an open exposed place with open field or distant views.

Be careful when using agricultural chemicals such as fertilizers, fungicides and insecticides etc. in the Polycarbhouse. Do not use

chemicals that are for outside use only. Always read the labels very carefully.

Do not push or lean on the PolyCarb panels. Do not lean weighty objects onto the PolyCarb. Use extra care when moving heavy

or awkward objects such as tables, poles, internal frames etc. within or near the Polycarbhouse.

Do not latch the door when anybody is inside the Polycarbhouse. Do not occupy the Polycarbhouse in times of high wind or

poor weather (hail etc)

Be aware of the increased temperature in the Polycarbhouse on a sunny day & allow for shading, or extra ventilation for these

higher temperatures.

Do not keep pets or other animals in the Polycarbhouse & try to prevent their entry.

When cleaning PolyCarb, do not exert too much pressure onto the PolyCarb.

Remember to fit the silver aluminium tape to the top edges of the polycarbonate sheeting before fitting them to the

greenhouse

Fit the 20mm square strongbacks (include a 75mm piece of the 20mm x 3mm white double sided tape at each end) after

installing the polycarbonate sheeting.

DETAILED ASSEMBLY INSTRUCTIONS

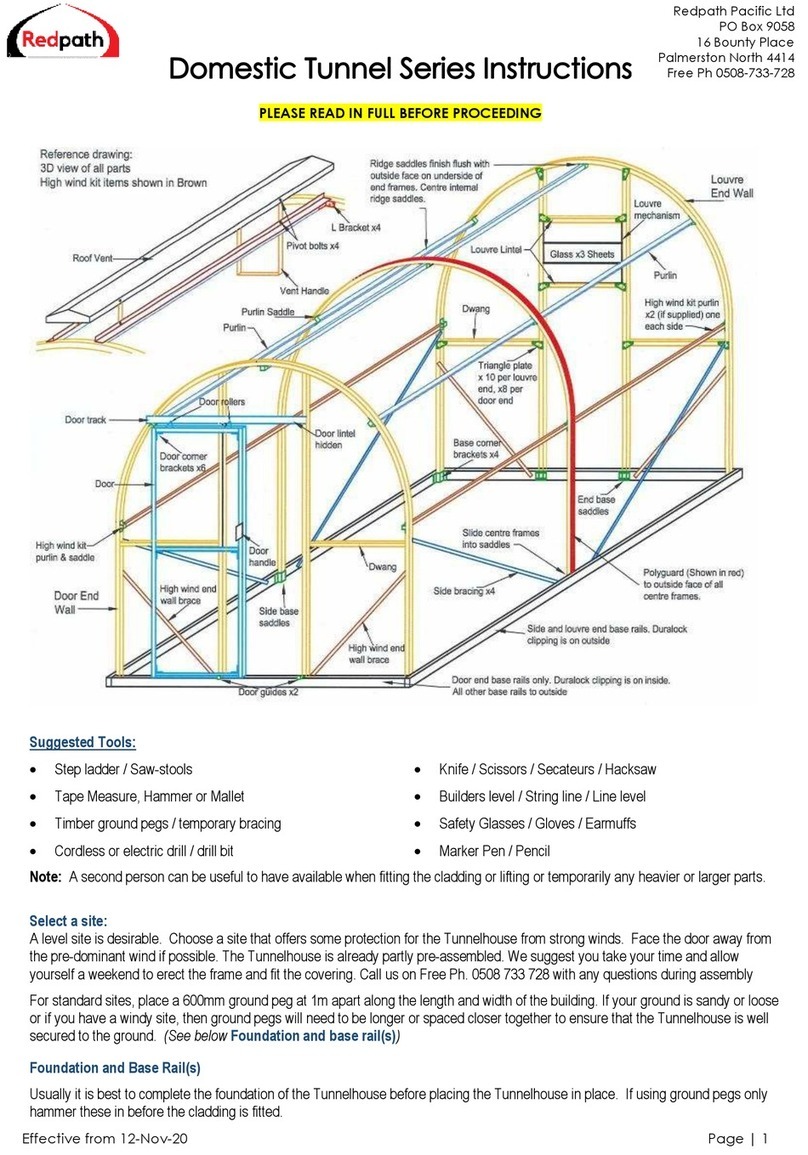

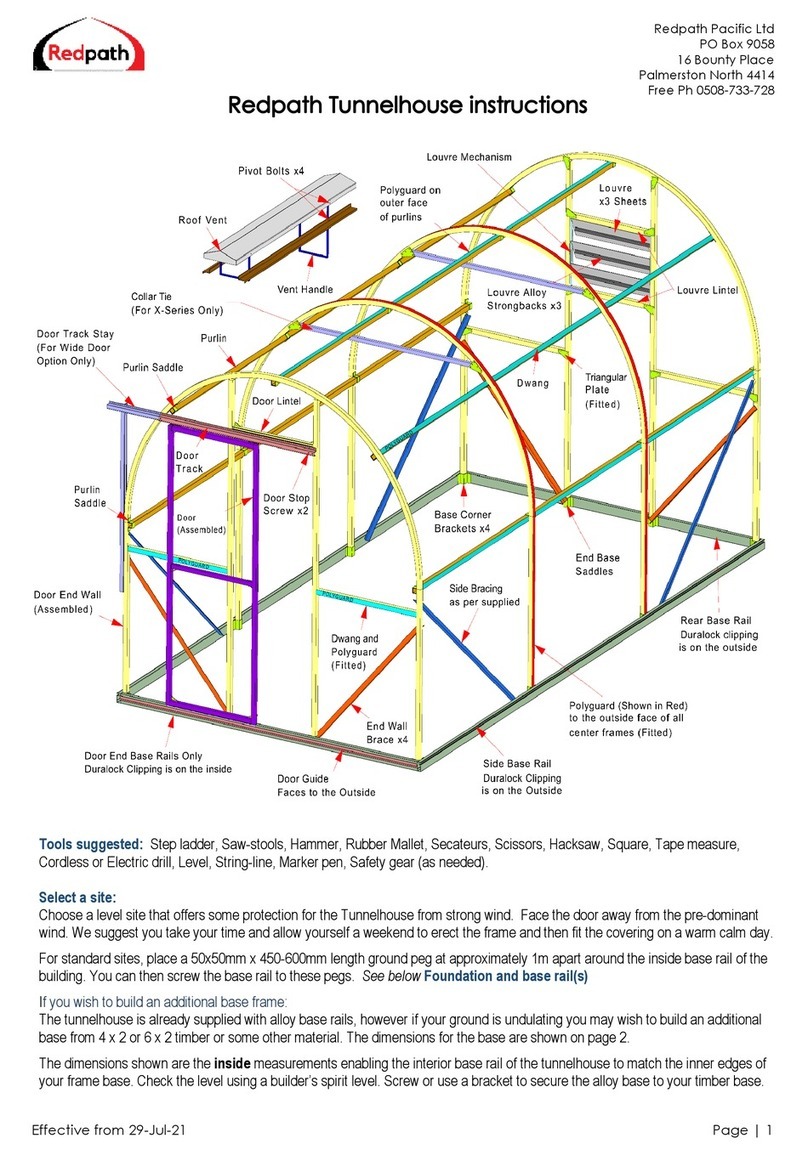

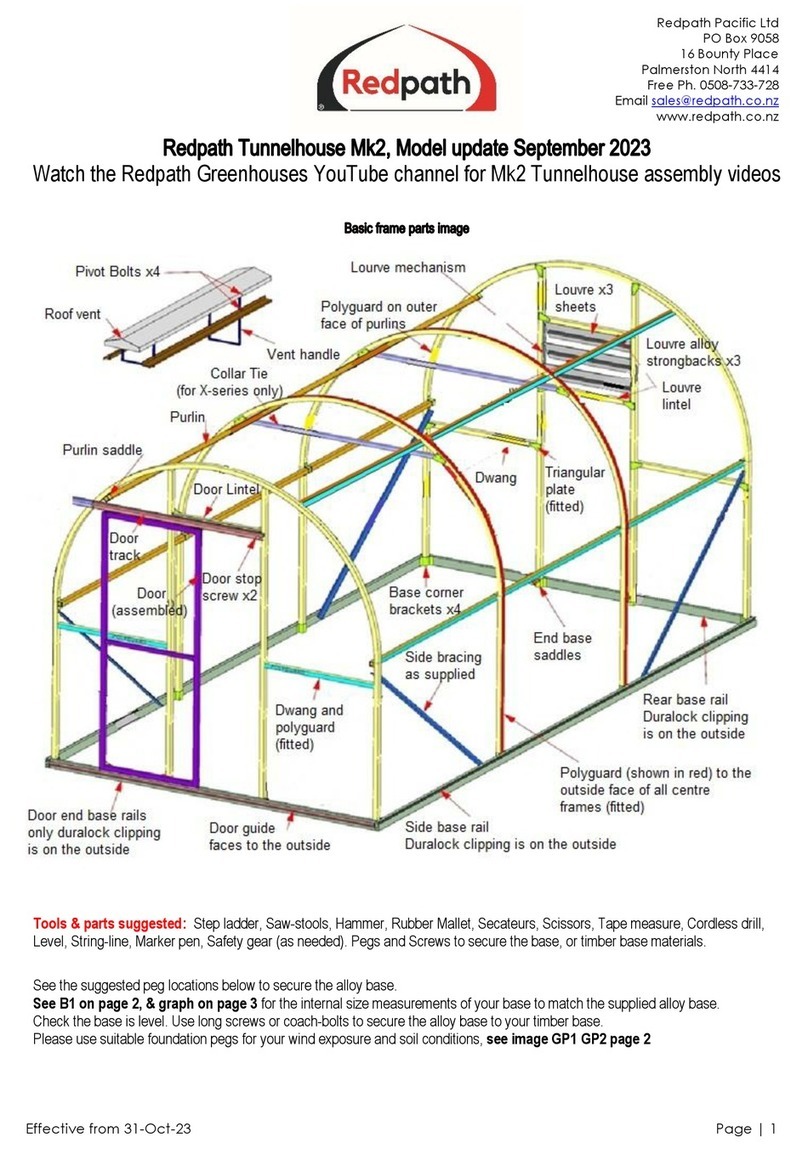

The contents of this carton are divided into the different frame assemblies that collectively make up the complete unit.

It is recommended that each frame assembly is fully completed before moving on to the next.

The frames to be constructed are as follows:

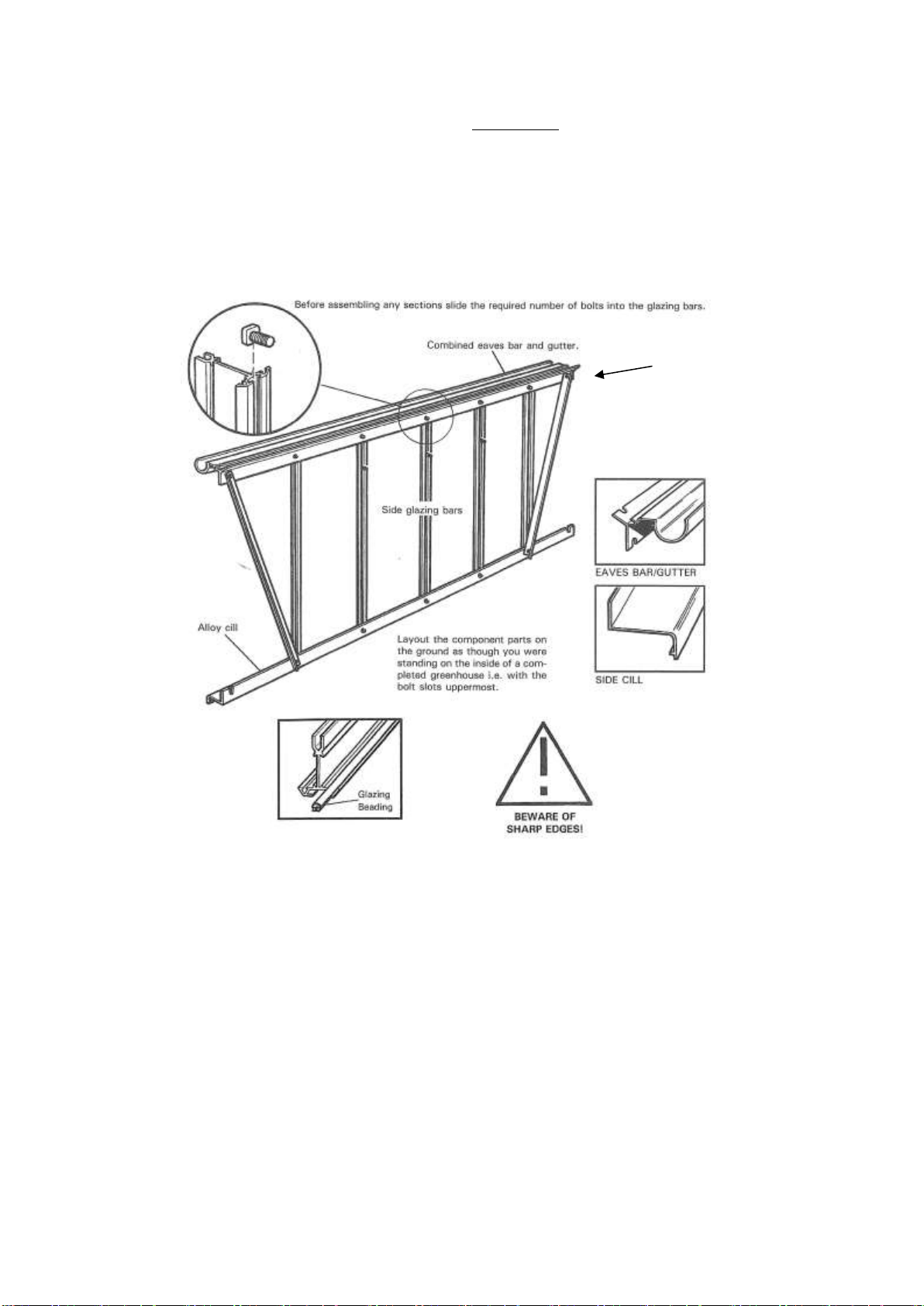

1. SIDE FRAME –Two off.

2. REAR GABLE –One off.

3. DOOR GABLE –One off.

4. ROOF VENT –Two for 2.57m x 3.80m and four for 2.57m x 5.04m.

5. DOOR –One off

6. CLADDING –All, including 20mm square aluminium ‘strongbacks’. Fit the aluminium foil tape to the top edges of each

sheet of polycarbonate before installing

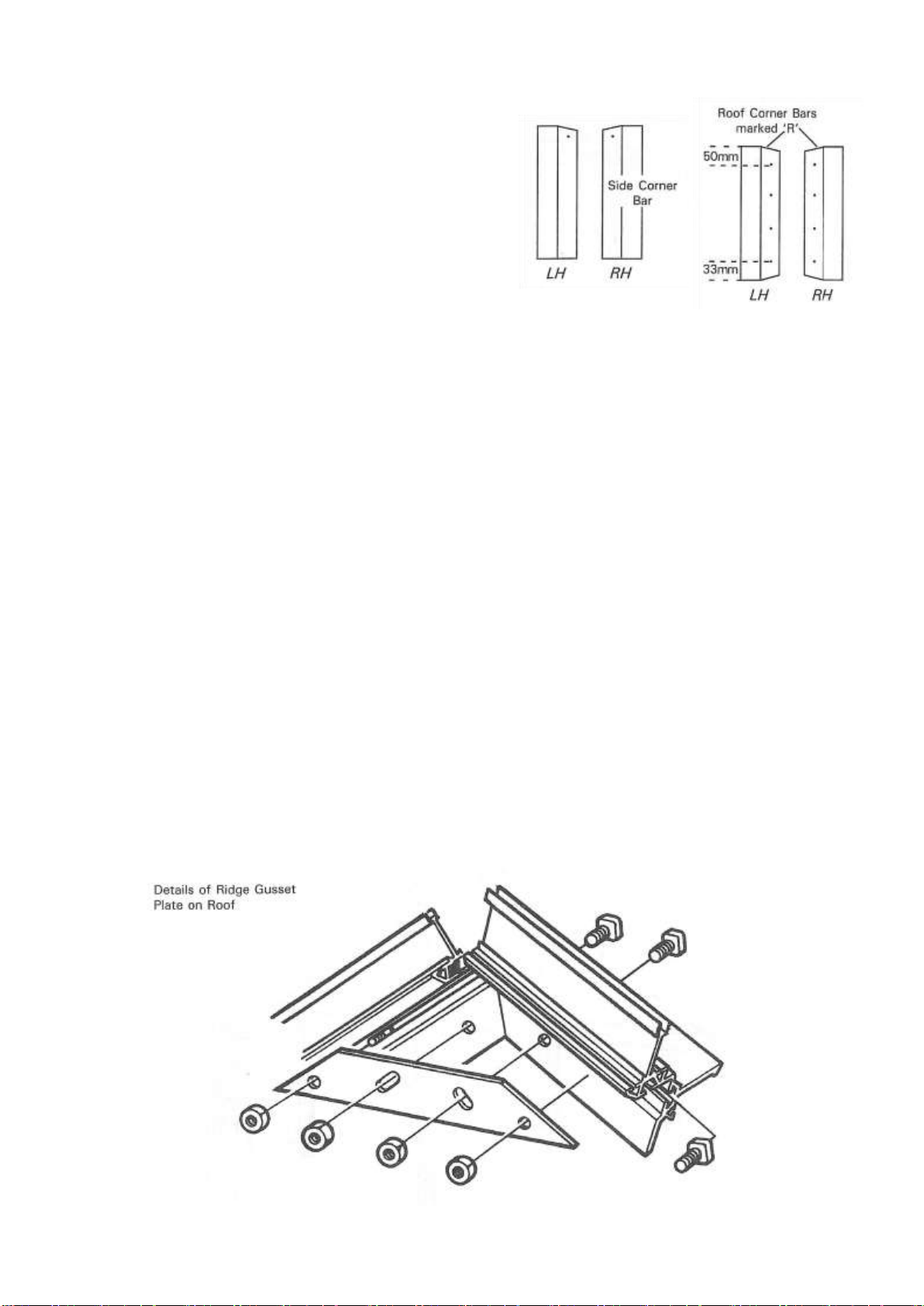

7. Additional parts such as the ridge, roof bars, eaves ties etc. are put on “loose” and are not pre-constructed into an

independent frame.