INSTALLATION INSTRUCTIONS

Inspection

Unpack and inspect the reel for damage.

Turn the reel by hand to check for smooth

operation. Check for completeness.

WARNING-PREVENT STATIC

SPARKING: When working around flam-

mable liquids such as solvents, paints,

chemicals or petroleum products, ensure

that the hose reel, hose and the equipment

being serviced are properly grounded.

Use grounded hose(s) (static wire). Use

an ohmmeter to check continuity of the

ground circuit. Fire and/or explosion can

result if proper grounding is not achieved.

If reel is power or air driven, be careful of

chain/sprocket drive system. Keep hands

clear. Do not wear loose fitting cloth-

ing. Pull hose from the reel by grasping

the hose itself, not the control handle or

swivel.

Maximum Operating Temperature

Low pressure (300 PSI) = 150 °F (66 °C)

Medium pressure (3000 PSI) = 210 °F (99 °C)

High pressure (4800 PSI) = 210 °F (99 °C)

Mounting of All Hose Reels

NOTE: Ensure that mounting surface is

flat to prevent binding on reel after it is

mounted.

1. Two 1/2” diameter mounting holes are

located at the base of each side

support panel (2 each). Mount reel

using four (customer supplied) bolts;

tightening them securely to ensure a

solid, rigid attachment.

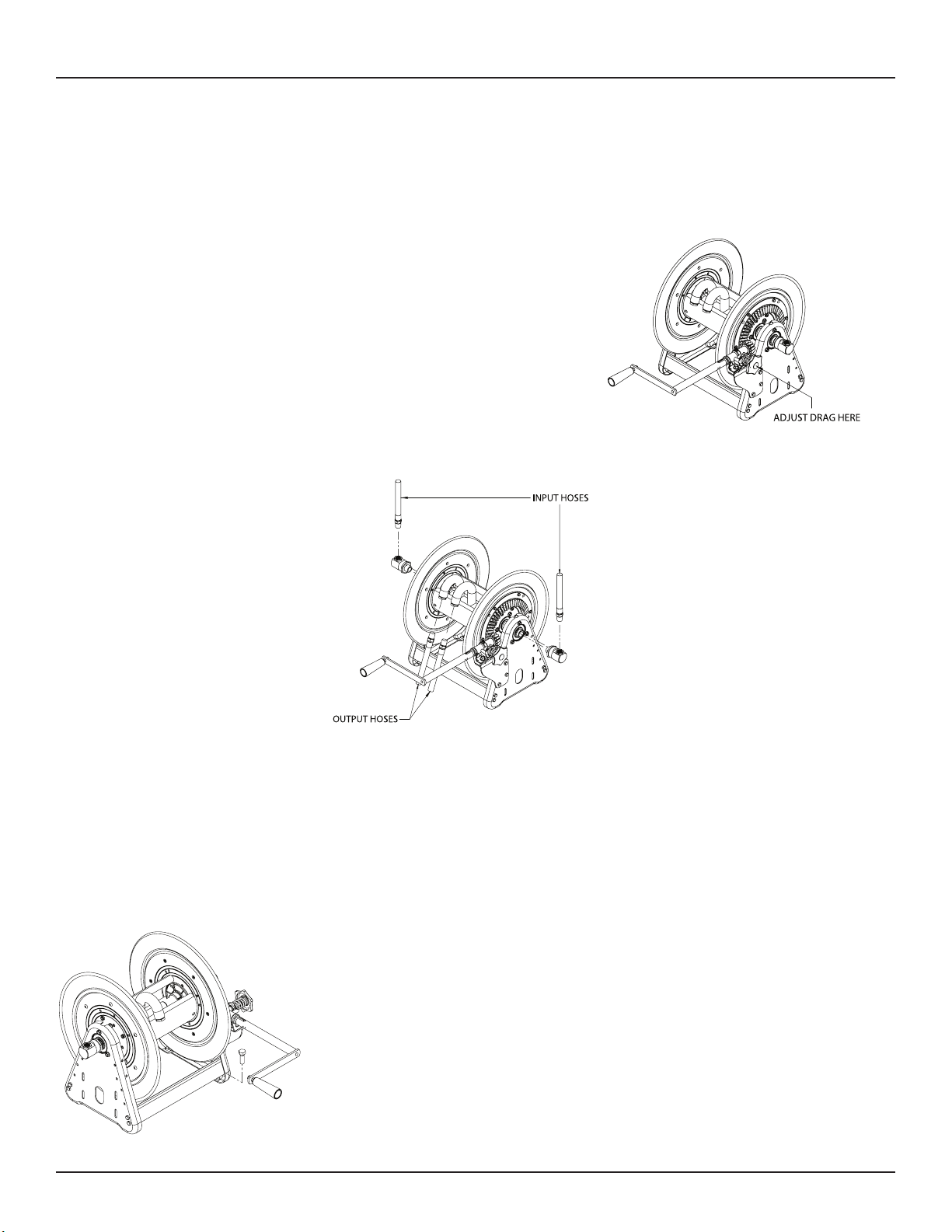

Installing the Input Hose(s)

WARNING: Ensure that supply line pres-

sure does not exceed maximum working

pressure rating of reel. Apply pipe thread

sealant where applicable to all threads on

standard reels. Do not over-tighten con-

nection.

CAUTION: A flexible hose connection

must be used to compensate for any off-

set between the supply line and the reel

swivel. Do not use rigid plumbing.

1. Apply thread sealant as directed and

connect swivels to main shaft inputs

on opposite sides of the reel.

2. Connect customer supplied supply

line hose to swivel input as indicated

in illustration.

Installing the Output Hose(s)

WARNING: Ensure that supply line pres-

sure does not exceed maximum working

pressure rating of reel.

CAUTION: Apply pipe thread sealant

where applicable to all threads on standard

reels. Do not over-tighten connection.

1. Connect output hoses to goosenecks

paying special attention to which

gooseneck should be used depending

on application. The left inlet is con-

nected to the left gooseneck and the

right inlet to the right gooseneck.

2. Charge hoses. Momentarily open

control valve to purge hose of gases.

When fluid appears at control valve,

close valve. With hose fully charged,

wind output hoses onto reel.

ADJUSTMENT PROCEDURES

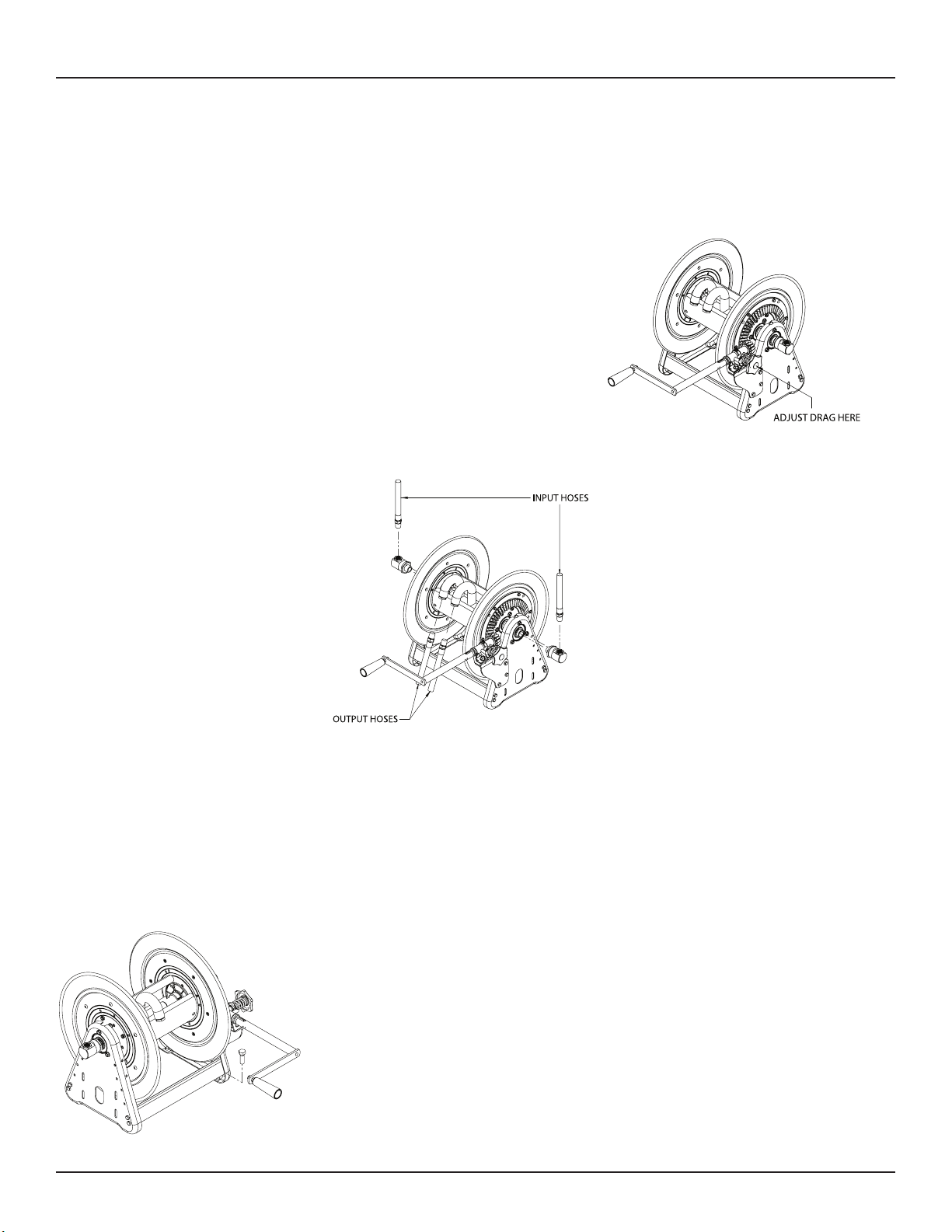

Adjusting the reel

1. Adjust reel drag by loosening or

tightening the knob on the side of the

hand rewind assembly.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to

replacing input/output hoses only. Refer

all other repairs to an authorized service

person or directly to Reelcraft. Failure to

do so can result in personal injury and/

or equipment damage and may void the

warranty.

WARNING: Bleed pressure from system

before servicing reel.

1. Replace hoses in accordance with

procedures given in “Installation In-

structions” section of this manual.

2. All mating moving parts have been

factory lubricated as required.

Series BA34000 M Hand Crank Reels

Page 2 www.reelcraft.com