Installation Instructions

Dual Cam II Part Number(s):

66091, 66092, 66093

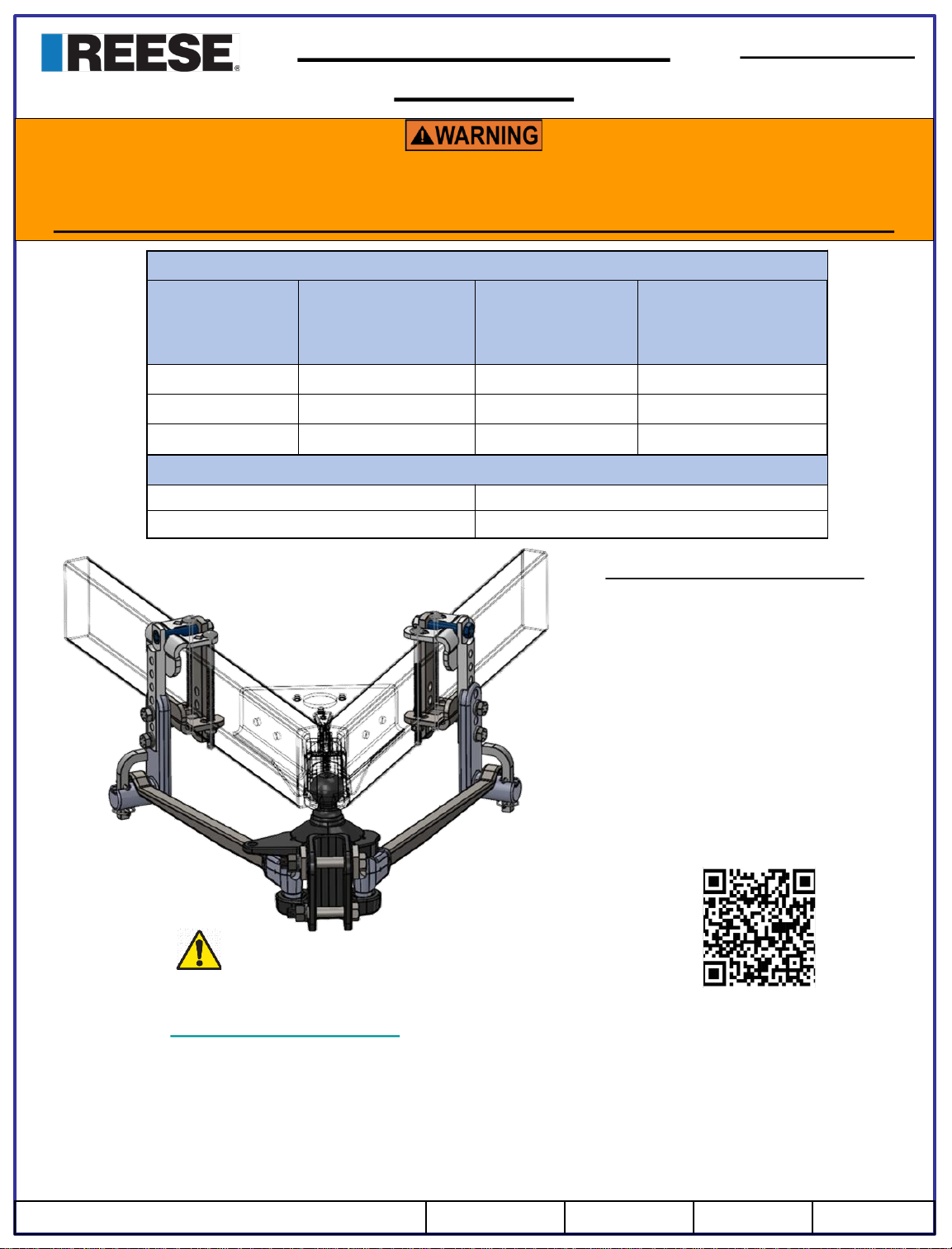

Experience the ultimate in sway control and weight distribution. The Dual Cam II, High Performance System

continually works to ensure the highest level of towing safety. The stronger the sway force, the more the

Dual Cam II System works to stop it. It’s the difference between active sway and passive sway control

where our unique design literally forces the trailer to stay in a straight line behind the tow vehicle. The newly

redesigned Dual Cam II system is now easier than ever to install and offers even broader application

coverage to work with the most popular trailer frames.

➢Fully automatic, active sway control system forces trailer to stay straight behind tow vehicle

➢No Drill installation

➢No need to relocate items on top of A-Frame to install Dual Cam II High-Performance Sway Control

➢Simple installation and adjustment

➢Hooking up spring bars automatically hooks up sway control

➢No U-bolts to interfere with bottle racks or another A-Frame mounted items

➢Limited lifetime warranty

➢Reduced noise when traveling

➢Rated for weight carry of 10,000 lbs

➢Includes pre-torqued 2-5/16” hitch ball

➢Works with both 1-1/2” and 2” frame widths

➢Works with frame heights of 4”-7”

Frequently asked questions:

➢What is a Weight Distribution Kit / Hitch?

Ans: Weight distribution kit or hitch is a system where it acts as a leverage between the tow vehicle & the

trailer causing the Tongue weight to be carried by all axles of the tow vehicle & trailer.

➢What is Gross trailer weight , Tongue weight & FALR?

Ans: Gross trailer Weight: Weight of a fully loaded trailer, inclusive of cargo.

Tongue Weight: The downward force that is exerted on the hitch ball by the trailer coupler.

FALR: Front Axle Load Restoration

➢Is a Sway Bar needed with this kit?

Ans: The kit is built in with a Sway prevention. Sway bars are not required.

➢Can the Kit be used on an Aluminum trailer?

Ans: Yes, the kit can be installed on an aluminum trailer. However, an Isolator shall be used to avoid

Galvanic corrosion. Polypropylene tape or a heavy-duty Packaging tape maybe used as an Isolator.

➢Can a lower rating Spring bars be used to tow higher load?

Ans: No, Higher loads cannot be towed with a lower rated Spring Bars.

©2022 Horizon Global America Inc. Page 2 of 16 66091N 02/03/2022 Rev. E