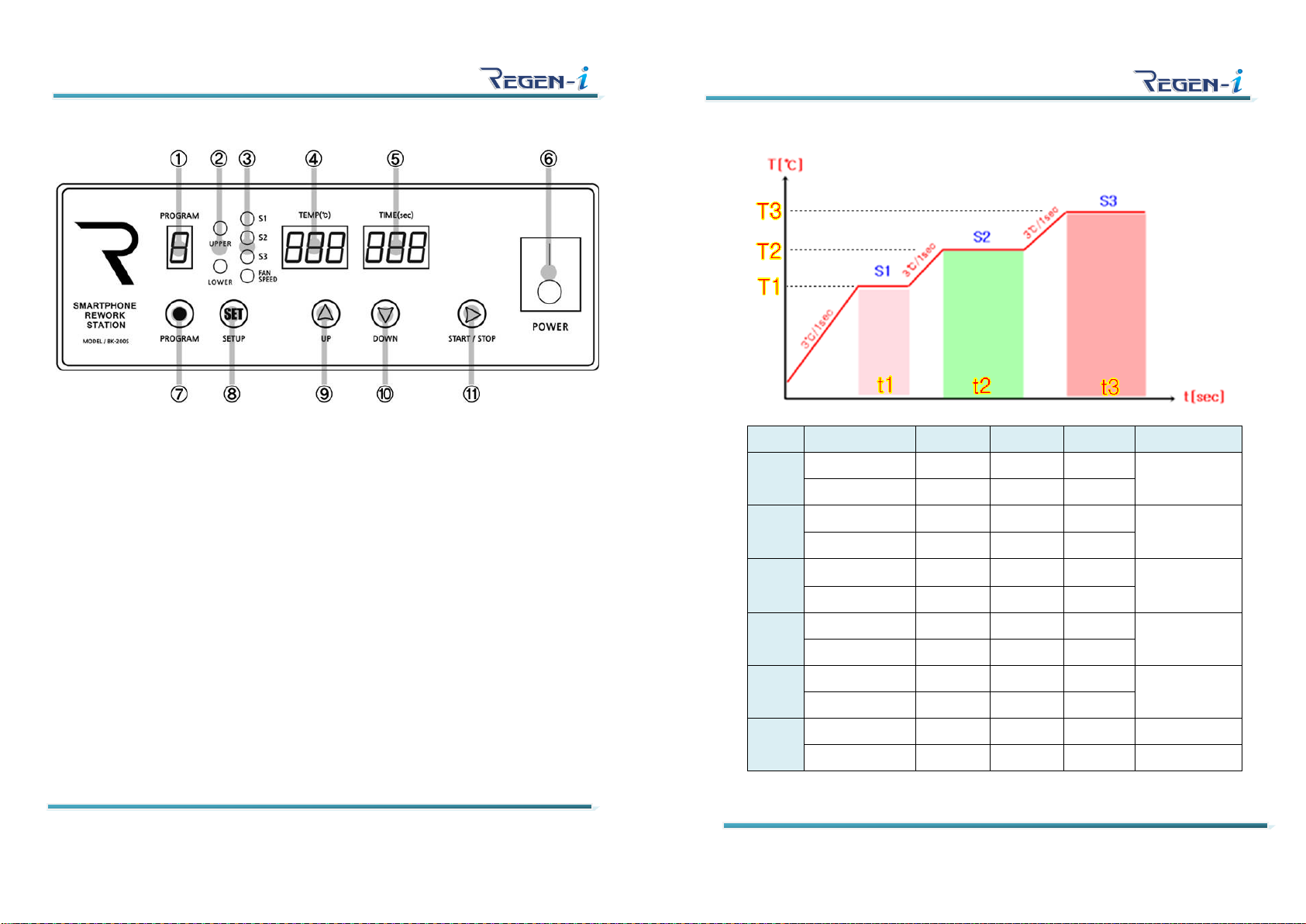

6) Start and Stop for Heating

①Heating Start: Heating is started based on the selected program.

From the current temperature to the set temperature of STEP1,

temperature is increased at 3 degree per second. When set

temperature is reached, the temperature is maintained for a period

of time of setting values. After that, heating is carried out according

to the set values of STEP2 and STEP3.

②Extension time: Each time the "UP" button is pressed once in

STEP3, the heating holding time can be further extended by 30

seconds.

③Stop: When you press the Stop button to terminate the heating

operation, upper and lower heater will cool down to 40 degree. After

that, cooling function will stop and the system will switch to standby

mode.

④Restart: When you resume the heating operation after pressing

program stop button, the heating does not proceed at temperature

higher than 80 degree even if start button is pressed. As the

temperature drops to 80 degrees or less, the heating operation can

proceed.

⑤Heating Pause of Upper heater: In order to stop the heating of the

upper heater during operation, if the upper heater is pushed back

about 4 cm, a physical weak jam is confirmed and its power is cut

off. The fans will continue to operate and "UP" and "OFF" will

illuminate on the temperature display. At this time, the program in

progress is continued, and when the upper heater is pulled forward

again, the pause function is canceled and the Upper heater begins

to rise to the temperature of the current ongoing stage.

5. Maintenance of the products

1) Unplug the power cable when the product is cleaned.

2) Use dry cloths when the product is cleaned.

3) Do not store flammable materials near equipment as this is a heating

device.

4) Tearing down of the products is strictly prohibited. We will not be

held responsible for malfunctions caused by disassembly.

5) When the product is not in use for prolonged period of time, remove

the power plug from electrical outlet and store in a dry place.

6. Troubleshooting

1) When the product does not turn on

①When smoke is emitted from the upper heater or the lower heater

during operation. Power off immediately and ask for A/S

consultation.

②Check the power supply.

③Make sure if the upper heater is pushed backward.

(At the start of heating, the upper heater must be fully pulled to

the front.)

④Check if it is not a power failure.

2) When temperature does not rise.

①Check if the temperature rises during heating.

②Make sure if the upper heater is pushed backward.

(At the start of heating, the upper heater must be fully pulled to

the front.)

③Check the operation statues of heater.

3) Error message

During malfunction, three times of buzzer sound, “beep” and error

message will be displayed as below.

①"UP" "th": Defective thermal sensor of Upper heater

②"LO" "th": Defective thermal sensor of Lower heater

③"U-H" "OFF": Improper temperature rise of Upper heater

④"L-H" "OFF": Improper temperature rise of Lower heater