2. INSTALLATION

2.1. Unpacking

2.1.1. Chair

2.1.1.1. Cut the shipping bands, open the top of the

shipping carton, and remove all packing material and boxes

that can be easily reached. Remove (4) nuts and remove

both base clamping boards.

2.1.1.2. It is recommended that the skid be positioned as

close as possible to the desired chair location.

2.1.1.3. Remove at least two small shipping blocks stapled

to the top of the skid. The chair can now be slid and/or

tipped from the skid onto the floor.

2.1.1.4. Do not lift the chair by the upper structure.

However, the chair may be tipped or slid into position by

pushing or pulling on the upper structure.

2.1.1.5. With the chair in positon, remove all remaining

paper pads, plastic, tape, strings, etc.

2.2. Assembly

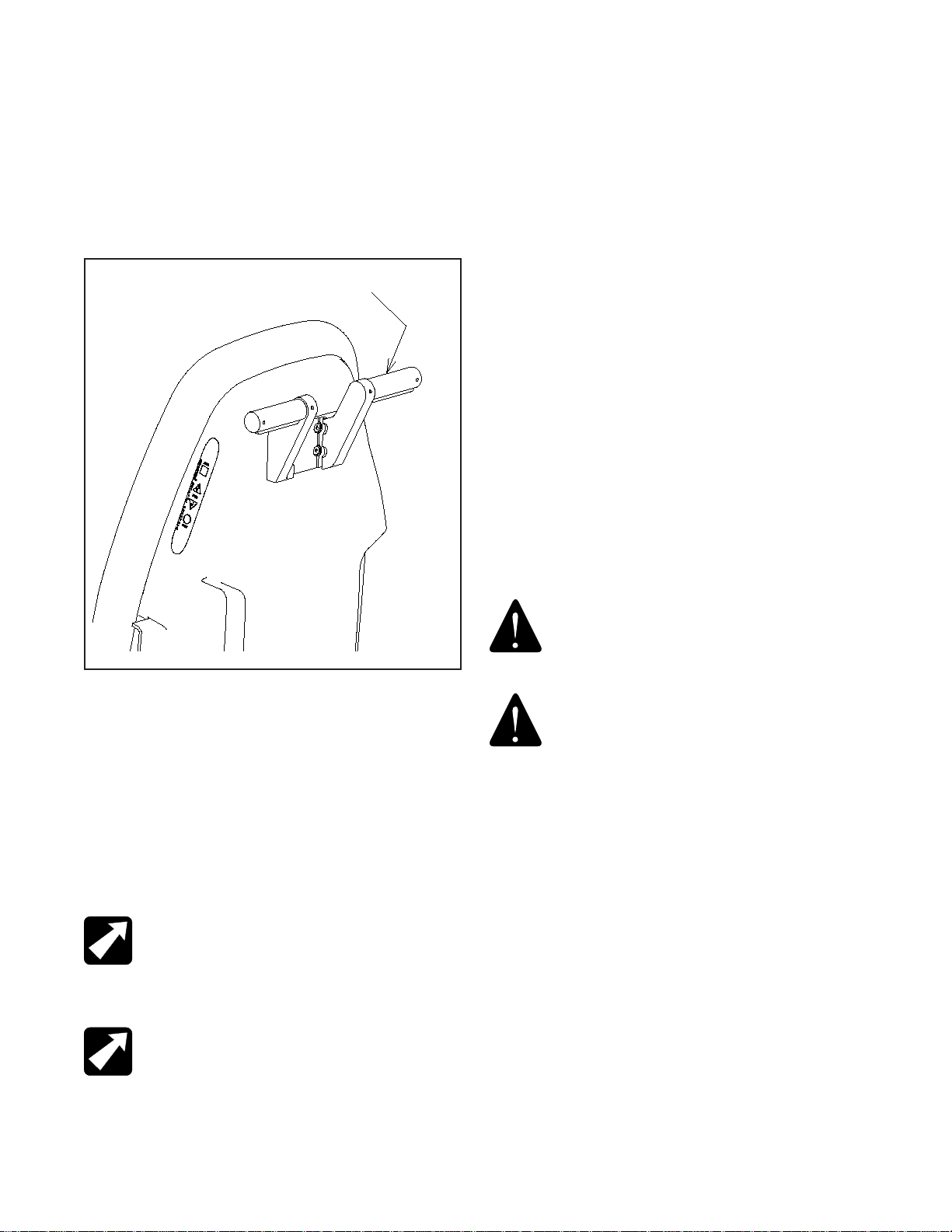

2.2.1. Headrest

2.2.1.1. Remove the headrest from its carton, and mount

it into position onto the chair back. Using the proper hex

key wrench, tighten the cap screw to clamp the headrest

securely into its mounting bracket.

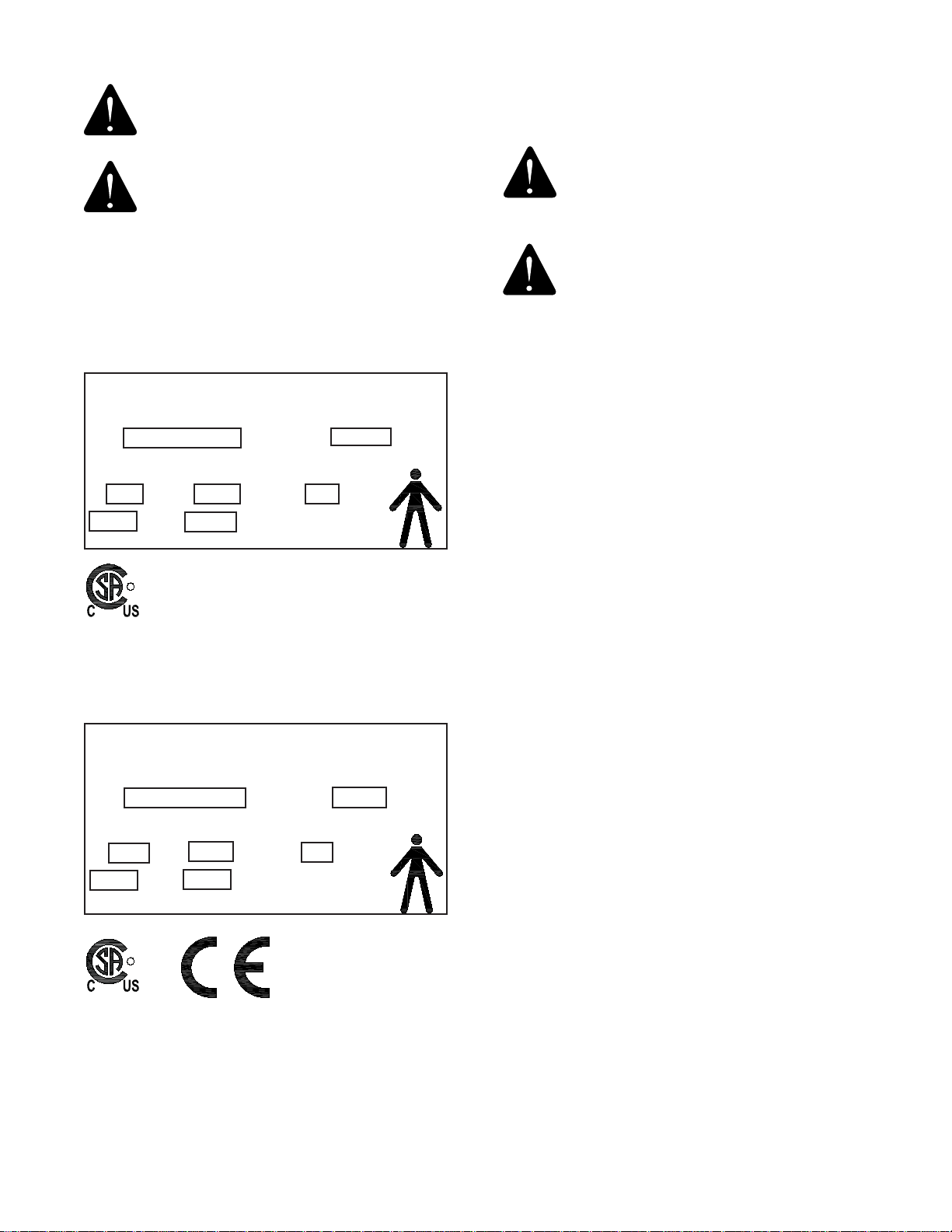

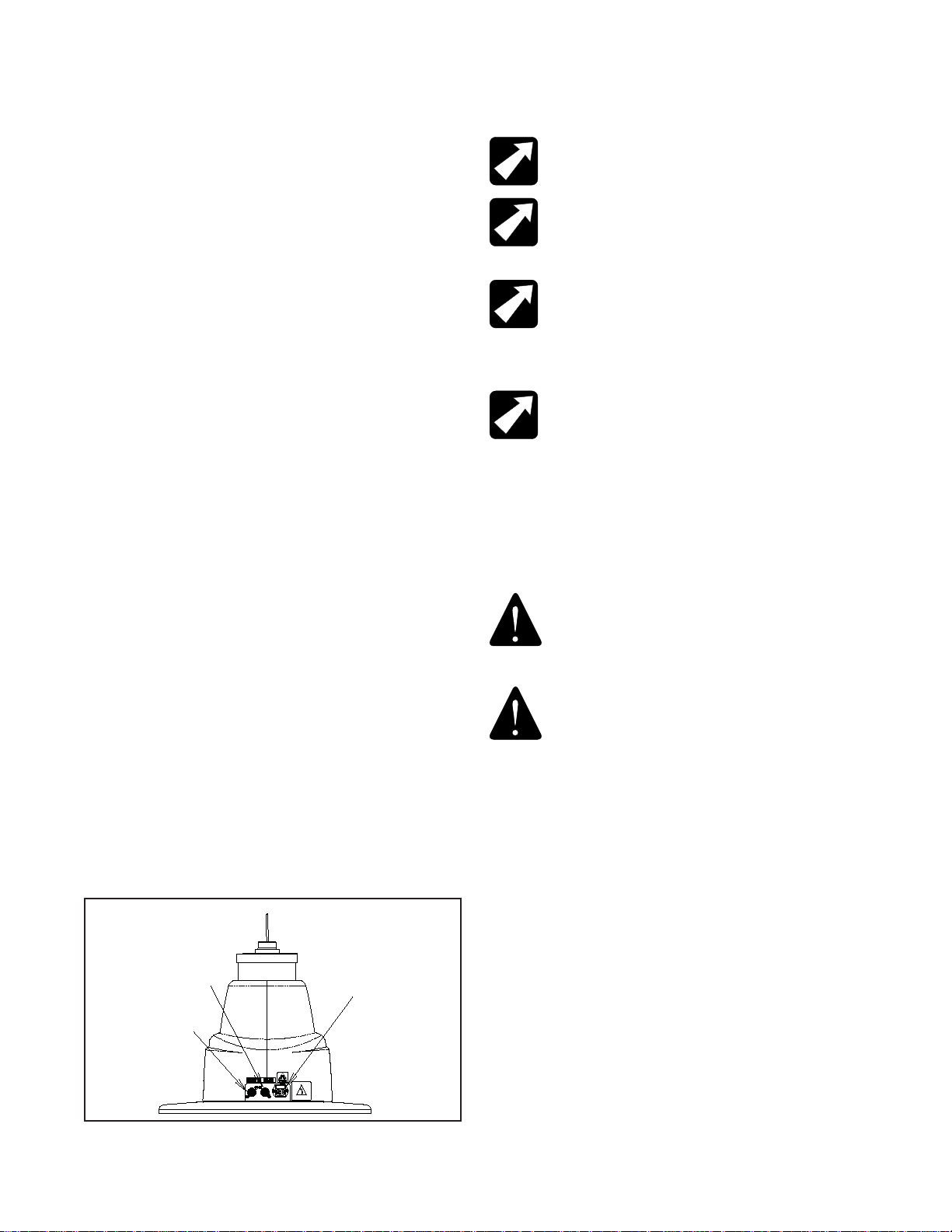

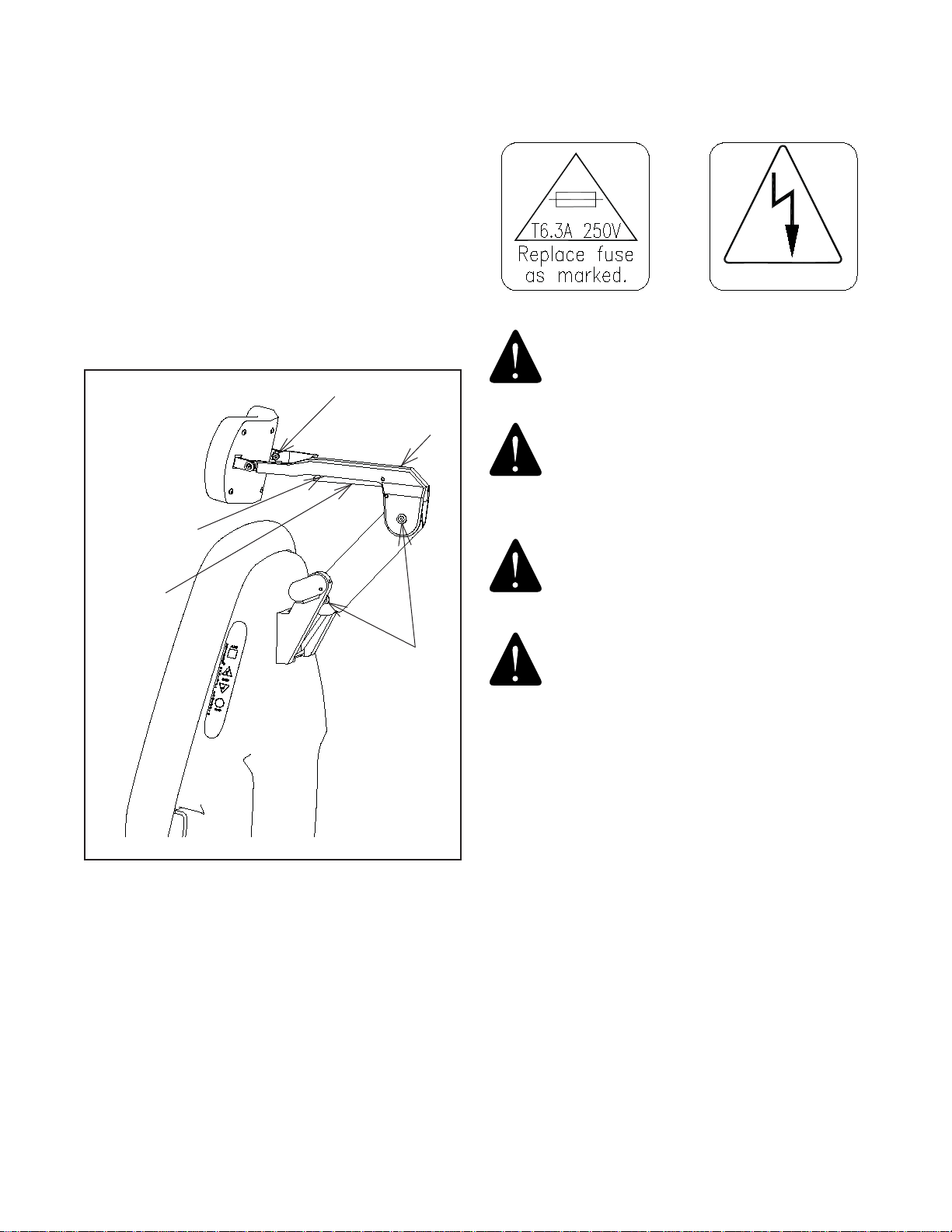

2.2.2. Power Receptacle

2.2.2.1. Locate the footswitch assembly, chair control

cable, and the power cord assembly. Refer to figure 1 for

receptacle location and attach all cables.

2.2.2.2. To disconnect power to Chair unplug power cord

from Instrument Stand or from wall receptacle.

NOTE: Outlet wires are hot.

NOTE : Les fils de sortie sont chaud

NOTE: If this chair is purchased in conjunction

with a Reliance® instrument stand, the chair control

cable supplied will provide proper operation. Refer

to the instrument stand manual for connection to

the stand.

NOTE: Si cette présidence est achetée

conjointement avec un gabarit d’instrument de

Reliance®, le câble de commande de présidence

fourni fournira le fonctionnement approprié. Référez

le manuel de gabarit d’instrument pour la connexion

au gabarit.

3. OPERATION

CAUTION- Caution should be taken to observe

that there are no obstructions (instruments,

trays, or tables) to impede the movement of

the chair.

ATTENTION- L’attention devrait être prise

pour constater qu’il n’y a aucune obstruction

(instruments, magasins, ou tables) pour

entraver le mouvement de la présidence.

Each time main power is applied to the chair, the circuit

board inside the chair will respond with a one second

beep. The beep indicates the electronics are functioning

properly.

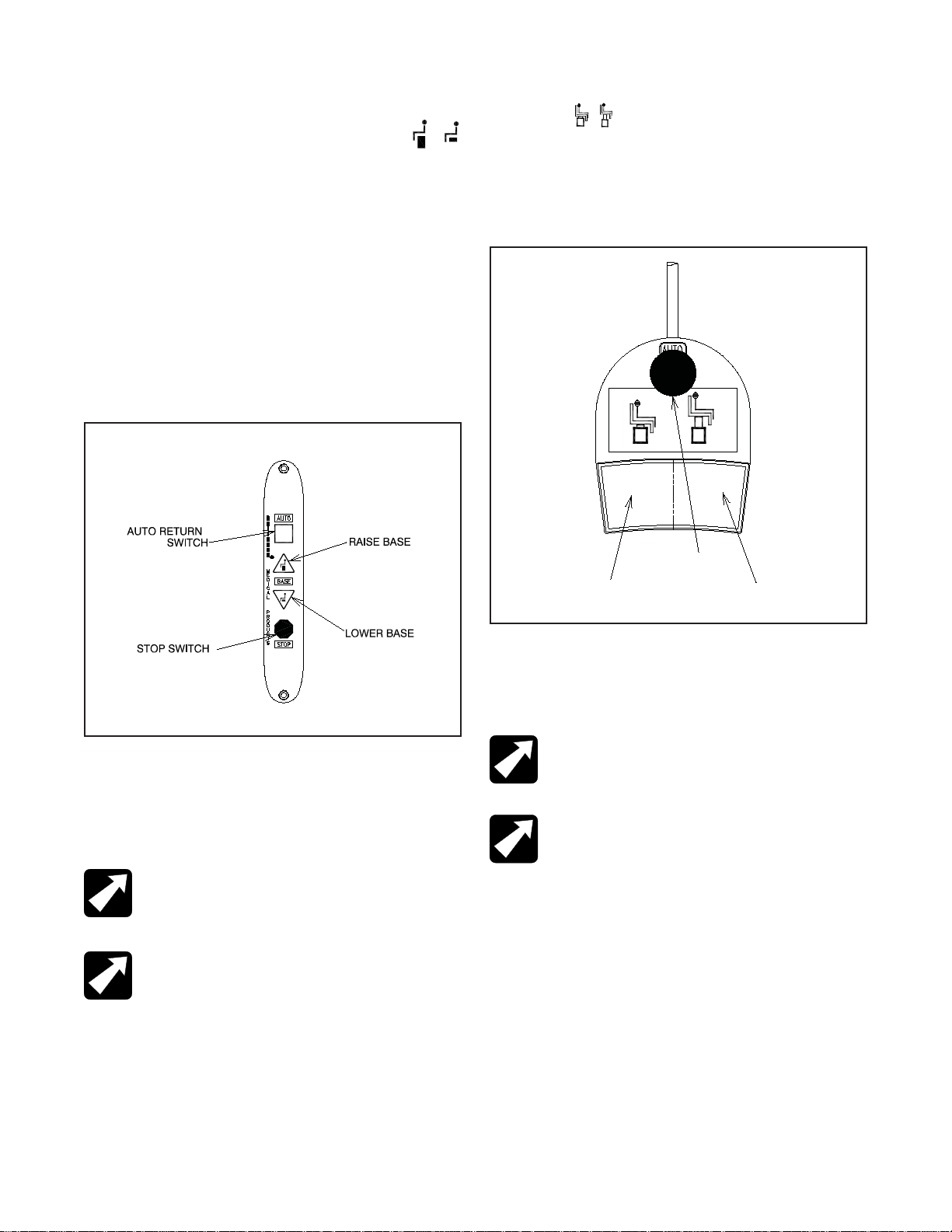

3.1. Stop Switch

3.1.1. Depressing the STOP switch on either side of the

chair back will STOP ALL movement of the chair. The STOP

switch is shaped like a stop sign, and may be either RED or

ORANGE in color. It is located above the text “STOP”. (Refer

to Figure 2).

FIGURE 1

BASE

Power Cord &

Fusedrawer

Footswitch

Cable

Chair Control

Cable

IN-FXM920 7