AVERTISSEMENT : POUR ÉVITER

UNE BLESSURE OU UN DOMMAGE À

L’ÉQUIPEMENT, SEULS LES DISTRIBUTEURS

RELIANCE® AUTORISÉS DEVRAIENT

INSTALLER OU DÉPLACER L’ÉQUIPEMENT.

WARNING: TO PREVENT FIRE OR

ELECTRICAL SHOCK HAZARD, DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR

MOISTURE.

AVERTISSEMENT : POUR ÉVITER UN

INCENDIE OU UN RISQUE DE CHOC

ÉLECTRIQUE, N’EXPOSEZ PAS CET

ÉQUIPEMENT À LA PLUIE OU À L’HUMIDITÉ.

WARNING- TO AVOID PERSONAL INJURY

OR DAMAGE TO THE EQUIPMENT, ONLY

TRAINED/QUALIFIED PERSONNEL WHO

HAVEREAD THISMANUAL SHOULDOPERATE

THIS EQUIPMENT. OPERATION BY UNAU-

THORIZED USERS SHOULD BE PREVENTED.

AVERTISSEMENT : POUR ÉVITER

UNE BLESSURE OU UN DOMMAGE À

L’ÉQUIPEMENT, SEUL DU PERSONNEL

ENTRAÎNÉ/QUALIFIÉ QUI A LU CE MANUEL

DEVRAIT FAIRE FONCTIONNER CET

ÉQUIPEMENT. LE FONCTIONNEMENT

PAR DES UTILISATEURS NON AUTORISÉS

DEVRAIT ÊTRE ÉVITÉ.

WARNING- TO AVOID PERSONAL INJURY OR

DAMAGE TO THE EQUIPMENT, CALL YOUR

AUTHORIZED RELIANCE® DISTRIBUTOR OR

THE TECHNICAL SERVICE DEPARTMENT IF

ANYPART OFTHE EQUIPMENTFAILS. ONGO-

ING USE OF MALFUNCTIONING EQUIPMENT

IS NOT RECOMMENDED.

AVERTISSEMENT : POUR ÉVITER

UNE BLESSURE OU UN DOMMAGE À

L’ÉQUIPEMENT, APPELEZ VOTRE

DISTRIBUTEUR RELIANCE® AUTORISÉ OU

LES SERVICES TECHNIQUES SI UNE PARTIE

QUELCONQUE DE L’ÉQUIPEMENT TOMBE

EN PANNE. L’UTILISATION CONTINUE D’UN

ÉQUIPEMENT DÉFAILLANT N’EST PAS

RECOMMANDÉE.

IN-7900 5

1. INTRODUCTION

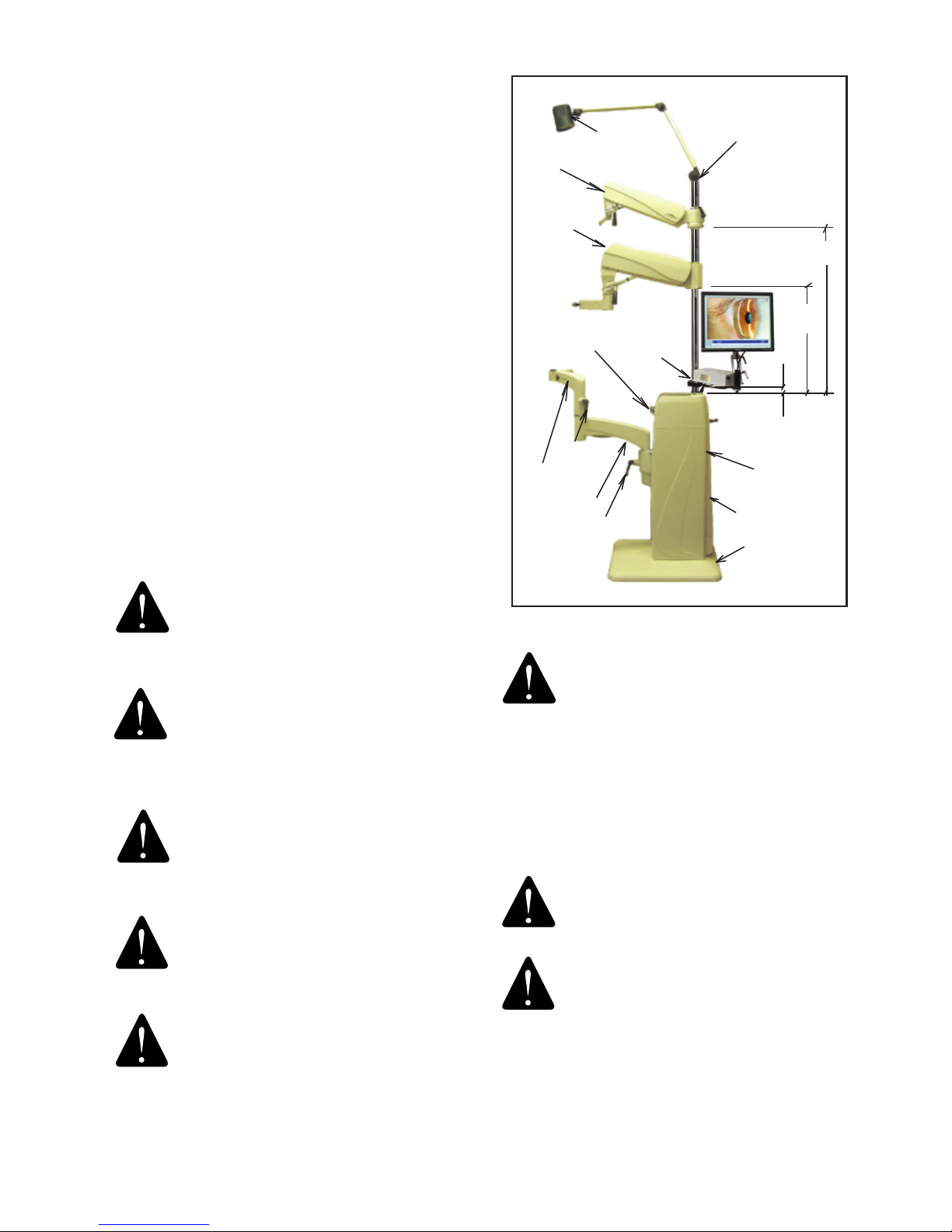

1.1. This Installation and Operating Instruction contains

information applicable only to the Reliance® Model 7900

Ophthalmic Instrument Stand also known as Floor Unit.

1.2. Should your product not perform properly, or if you

have any questions concerning the use and care of any

Reliance® product, contact the

Authorized

Reliance®

Distributor where you purchased this product or contact the

Technical Service Department, Reliance® Medical Products,

Inc., 3535 Kings Mills Road, Mason, Ohio 45040-2303, or

call (800) 735-0358.

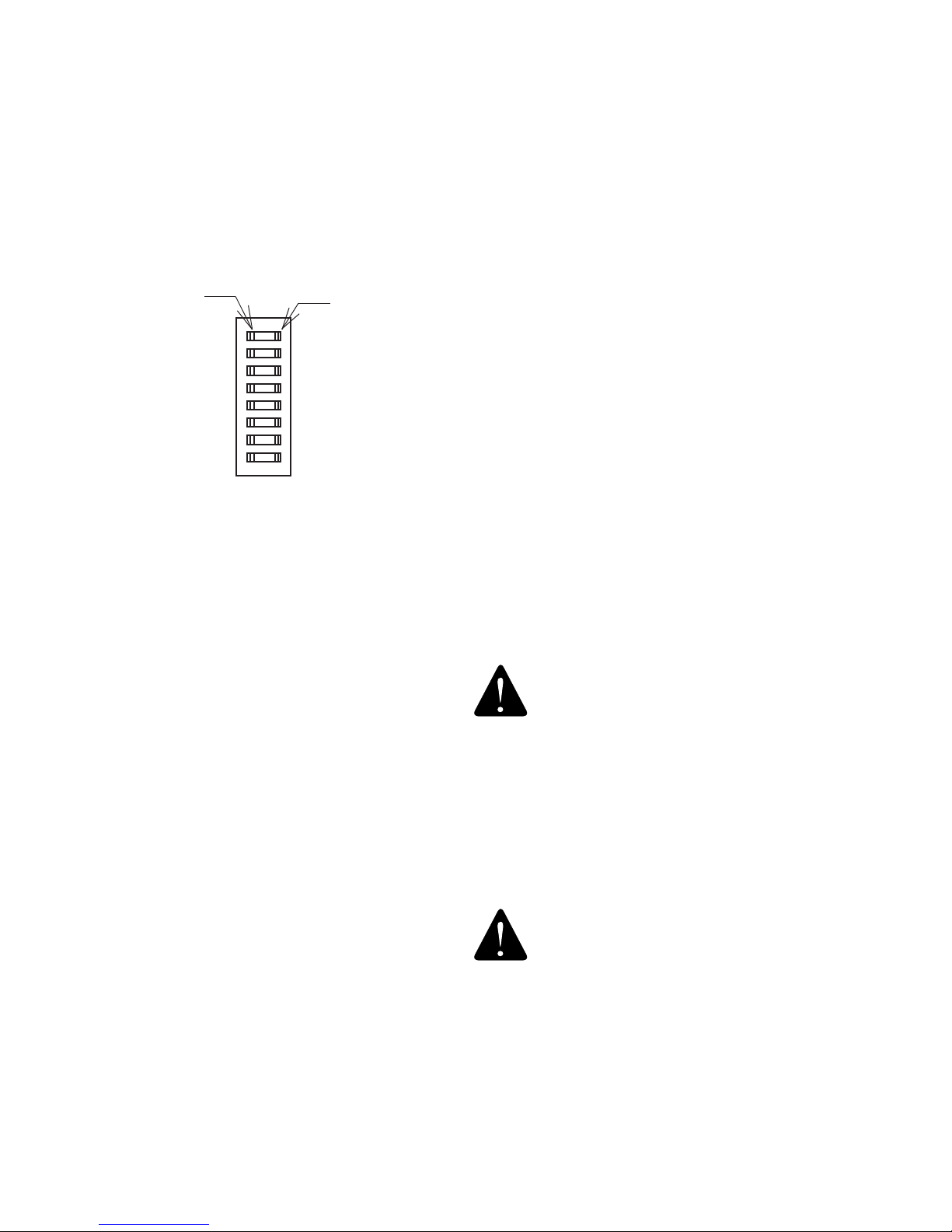

NOTE: Always have the model number and serial

number available before contacting Reliance® or

your Authorized Reliance® Distributor.

REMARQUE : Ayez toujours le numéro de

modèle et le numéro de série à portée de la

main avant de contacter Reliance® ou votre

distributeur Reliance® autorisé.

“CLASSIFIED BY CANADIAN STANDARDS

ASSOCIATION® CSA WITH RESPECT TO

ELECTRIC SHOCK, FIRE AND MECHANICAL

HAZARDS ONLY IN ACCORDANCE WITH IEC

60601-1.”

According to Clause 5 in IEC 60601-1, sec 6.8.1, this Unit

is classied by the following:

• The type of protection against electric shock:

EQUIPMENT energized from an external electrical power

source: CLASS I EQUIPMENT

• The degree of protection against electric shock: TYPE

B EQUIPMENT

• The degree of protection against harmful ingress of

water: ORDINARY DEGREE

• The degree of safety of application in the presence of a

FLAMMABLE ANESTHETIC MIXTURE WITH AIR or WITH

OXYGEN OR NITROUS OXIDE: EQUIPMENT not suitable

for use in the presence of a FLAMMABLE ANESTHETIC

MIXTURE WITH AIR or WITH OXYGEN OR NITROUS OXIDE

• The mode of operation: CONTINUOUS OPERATION

WARNING: TO AVOID PERSONAL INJURY

OR DAMAGE TO THE EQUIPMENT, ONLY

AUTHORIZED RELIANCE® DISTRIBUTORS

SHOULD INSTALL OR MOVE THE EQUIPMENT.