8

Optimum cooling mode

In “Cooling” mode, the air in the room is suctioned in by

the air-conditioning unit, filtered and then returned in a

cooled state back to the room. The warmth removed

from the room is guided to the outdoor part and expelled

to the surrounding air.

To keep the periods of operation of the outdoor part as

short as possible, the temperature setting of the room to

be cooled should only be kept as low as necessary.

Very low room temperatures mean longer periods of op-

eration and increase the amount of electricity used.

Temperature differences of 6 degrees or more below

the surrounding temperature of the room can give peo-

ple colds.

Optimum dehumidification mode

In “Dehumidification” mode, the air in the room is suc-

tioned in by the air-conditioning unit at periodic intervals,

filtered and returned to the room in a slightly cooled

state.

In this operating mode, the air is more dehumidified

than in normal cooling mode. The warmth removed

from the room is guided to the outdoor part and ex-

pelled to the surrounding air.

The ventilation capacity cannot be changed in this oper-

ating mode (constant preset fan speed).

Additional instructions for all operating modes

àThe indoor unit works most effectively with a clean

filter. The filter should be checked and, if necessary,

cleaned, 2 times a month.

àThe outdoor part must be checked for dirt and, if ap-

plicable, plants. Here as well, a decrease in the

quantity of air causes the cooling capacity to be low-

ered and hence to an increase in electricity con-

sumption.

Operating mode button (6)

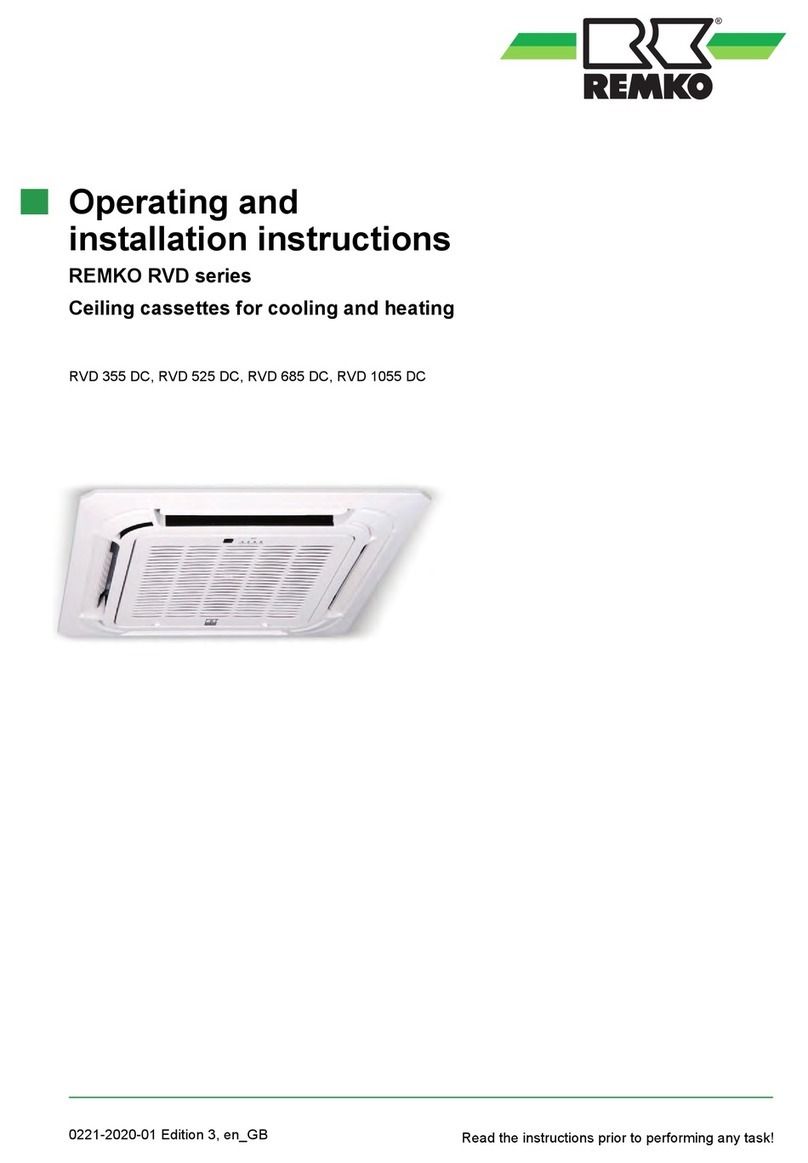

There are 3 operating modes available for using the

ceiling cassettes. The operating mode button can be

used to program the following functions:

– Ventilation (+ filtering)

– Heating (no function)

– Automatic (no function)

– Cooling (+ dehumidification)

– Dehumidification

The (6) button is pressed as many times as necessary

until the desired symbol appears on the display.

M

“Cooling” mode

In this operating mode, the room in the air is cooled and

slightly dehumidified. The following section

“Temperature selection buttons” describes how to set

the desired room temperature.

“Ventilation” mode

In this operating mode, the air in the room is not cooled.

The purpose of this function is to filter the air and/or cre-

ate a comfortable circulation of air. In the winter, warmth

that accumulates below the ceiling can be circulated.

“Dehumidification” mode

In this operating mode, the air in the room is dehumidi-

fied and slightly cooled. It is not possible to set the room

temperature in this mode.

Temperature selection buttons (8) (9)

The desired room temperature is set using the (8)

and (9) buttons.

The indoor unit confirms that the signal has been re-

ceived by beeping. The new temperature is displayed

on the remote control.

A temperature between 17 °C and 32 °C can be set in

1 °C increments.

If the room temperature is lower than the set tempera-

ture, the unit does not start.

If the room temperature is higher than the set tempera-

ture, a safety period of approximately 3 min. elapses be-

fore the unit starts. Only then does it begin.

If the unit has cooled the air in the room to the set value,

cooling mode switches off. The condensation pump

switches off after running for approx. 7 minutes.

Fan speed selection button (10)

By pressing the button (10), the fan speed and the air

quantity of the fan dependent on it can be selected. The

currently selected speed is shown on the display.

Optimum ventilation mode

The pure ventilation mode circulates the “standing” air in

the room.

It is often not necessary to lower the temperature. If this

is the case, the effect is similar to a ceiling fan. On cool

days, warmth that accumulates on the ceiling can be

transported downwards in this operating mode.

In ventilation mode, the air in the room is also filtered,

as already mentioned.

The following fan speeds are available:

Low (especially quiet)

Medium

High (greatest cooling effect)

Automatic mode (the fan speed

is adjusted to the respective

need for cold air)