Setting the Roller Harrow

Roller Height and Depth

The roller harrow and all its components are tightened to the machine, it is now time to set the

roller to the desired working depth for your machine application. Several steps are involved to properly

set your roller harrow. Improper settings can cause damage to harrow, which will not be covered under

warranty. Read carefully and follow each step to correctly set your Remlinger roller harrow.

1. Determine the operating depth your implement. This is key, mounted roller harrows work best

when the depth setting of the roller harrow is approximately 2 inches. Roller harrows that are set

less than 2” have a tendency of leaving an unsatisfactory nish. Roller harrows that are set more

than 2” deep can cause premature stress on the harrow components and cause failure that will

not be covered under warranty.

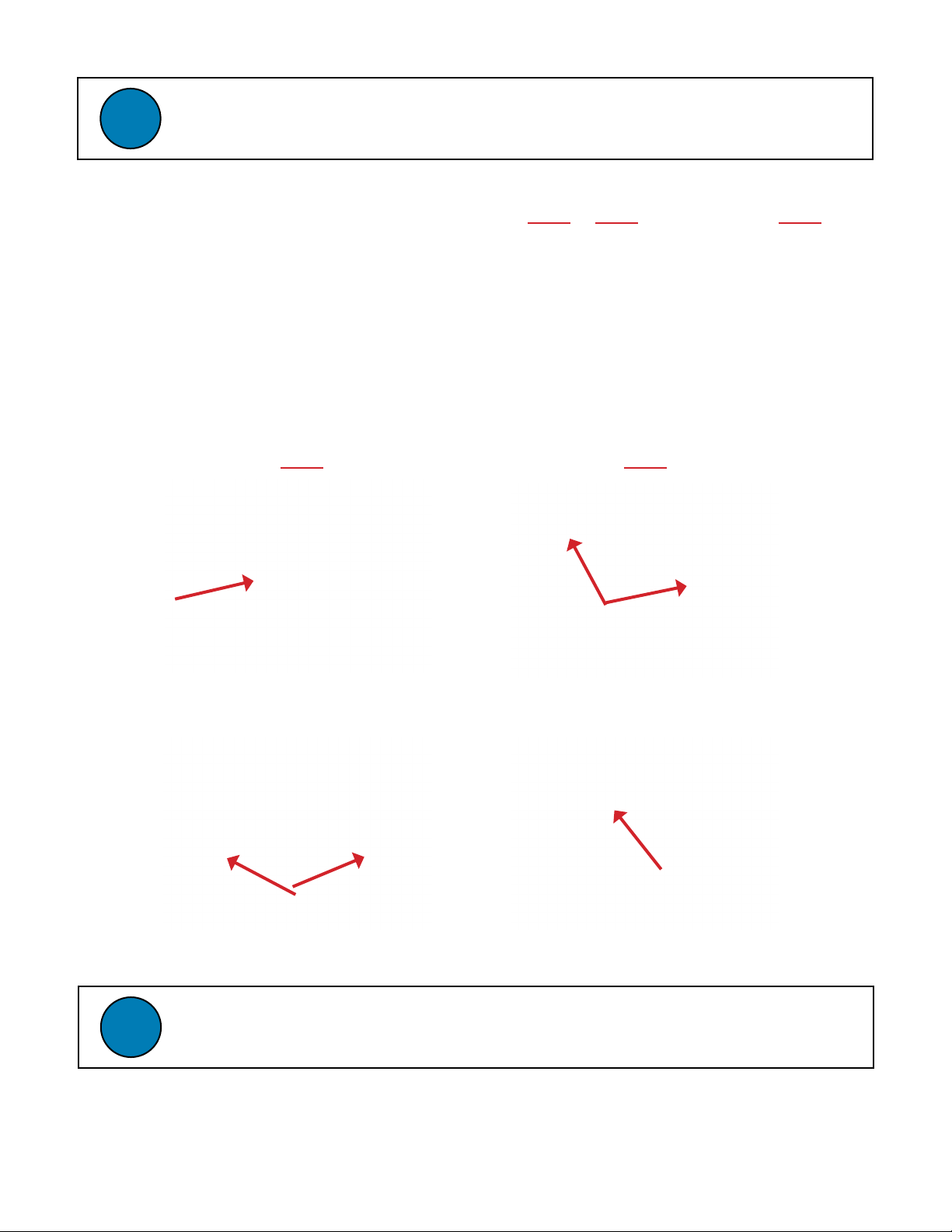

2. On a hard level surface, lower the implement down onto shovels, blades, shanks, etc. With

implement resting on the ground, a formula is used to decide how thick of spacer boards are

needed to set the roller height to obtain the recommended 2” roller working depth. For example,

implement is going to be working 4” deep in the ground, to obtain a 2” roller working depth, lay 2

spacer boards on the ground underneath each end of one roller section. This spacer board should

be approx. 2” in thickness. This will be repeated for each roller section mounted. Note: Spacer

boards from roller pallets are ideal to use.

Formula:

Implement Work Depth – 2” Roller Work Depth = Spacer Thickness

Steps 3, 4 and 5 will be done simultaneously before moving onto the next roller section.

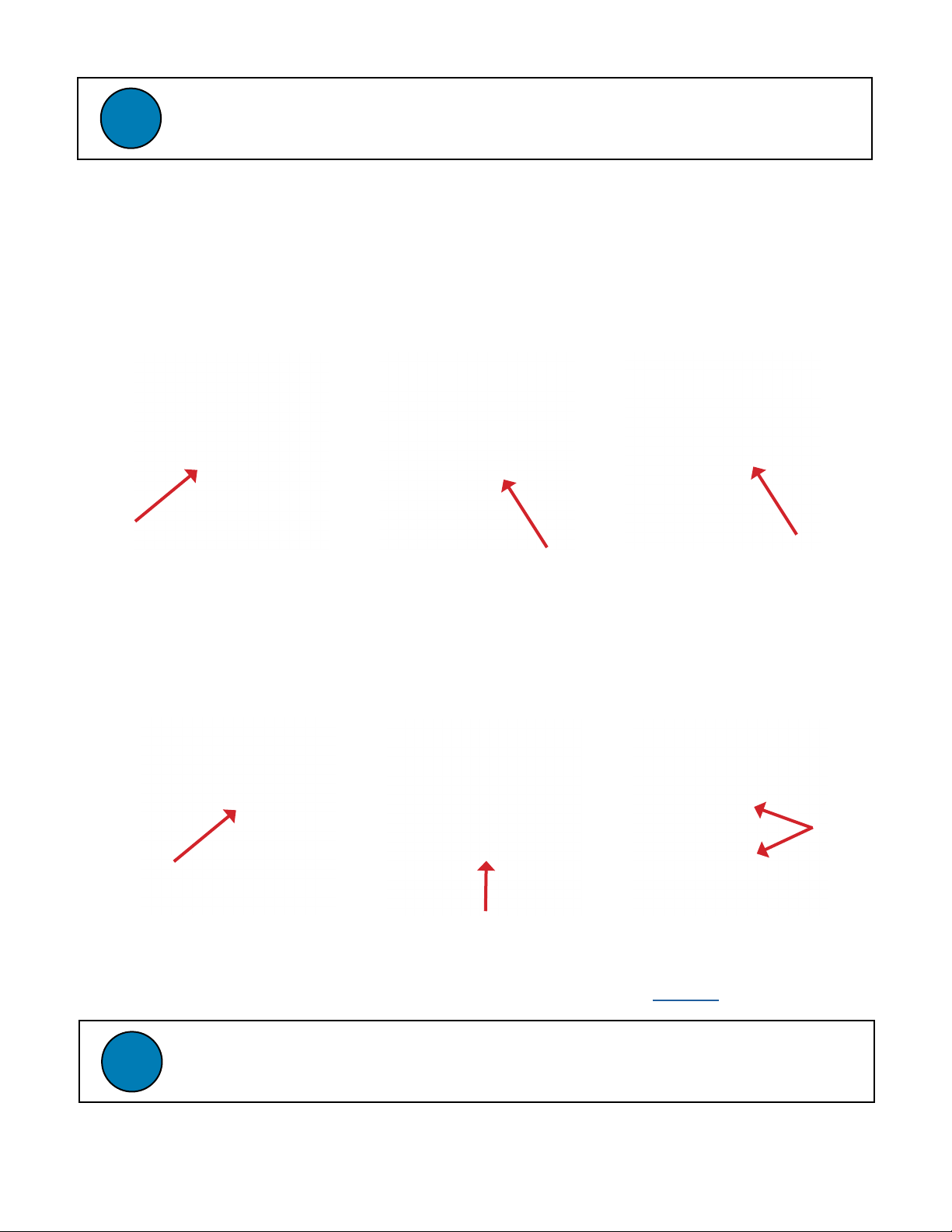

!

3. To set the height on your roller harrow, it is important to loosen all the fasteners and springs

that control the height of the arm. Loosen the 5/8” lock nut and ½” lock nut to allow arm to move

up and down freely. To decrease any spring tension from factory assembly, loosen the 5/8” jamb

nut on and turn threaded bolt counter clock-wise until spring is released of any tension.

Manual # - MAN-SRH-DFC-004

9

Remlinger Mfg reserves the right to change pricing or specications at anytime without notice or obligation

1-800-537-7370