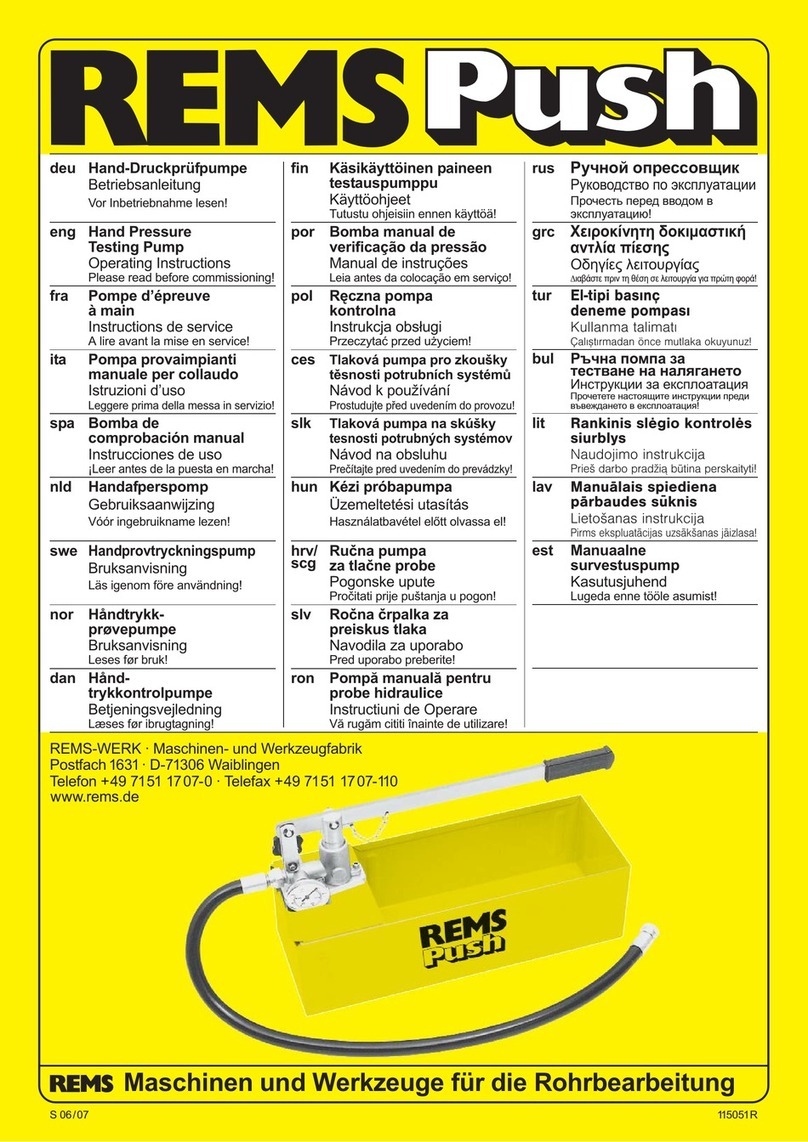

A Hand pressure testing pump

B Installed lines

C Connecting line

D Pressure gauge

E Shut-off valve

F Shut-off valve upstream of installed

system

Readallthesafetynotes,instructions,illustrationsandtechnicaldatawhich

comewiththisdevice. Failure to heed the following instructions can lead to severe

injuries.

Only use the tool for the intended purpose and under observance of the general

safety and accident prevention rules.

Untidiness in the work area can cause accidents.

Do not use weak machines for heavy work. Do not use the

tool for a purpose for which it is not intended.

Slightly damaged parts must be checked carefully

for perfect and proper functioning every time before using the tool. Check whether

the moving parts work perfectly and do not jam or are damaged. All parts must

be mounted correctly and meet all conditions to ensure perfect operation of the

tool. Damaged parts must be properly repaired or changed by a recognised

You can work better and safer in the specied work

Do not wear loose clothing or jewellery as these

can get caught in moving parts. Rubber gloves and non-slip shoes are recom-

mended for working outdoors. Wear a hair net over long hair.

Wear safety glasses. Wear protective gloves.

Make sure that you have a rm footing and

Keep the tools clean to work better and safer.

Follow the maintenance regulations and instructions. Keep handles dry and free

from grease and oil.

Do not expose your tools to rain. Provide

good lighting.

Do not let other persons touch your tools. Keep other

persons and especially children away from your work area.

l) Onlyusegenuineaccessoriesandgenuinesparepartsforyourownsafety

The use of other insertion tools and

accessories can cause you injury.

This tool satises the perti -

nent safety regulations. Repairs may only be done by a recognised specialist or

instructed person with the use of genuine spare parts, otherwise the user could

have an accident. All unauthorised modications to the tool are prohibited for

Safetyinstructionsforthehandpressuretestingpump

Readallthesafetynotes,instructions,illustrationsandtechnicaldatawhich

comewiththisdevice. Failure to heed the following instructions can lead to severe

injuries.

Thedevicedevelopsveryhighpressuresofupto6MPa(60bar,870psi).

So be very careful. Keep third parties away from the work area when working

with the device.

Examinethehigh-pressurehosesfordamageeverytimebeforeusing.

Damaged high-pressure hoses can burst and cause injury.

Onlyuseoriginalhigh-pressurehoses,ttingsandcouplingsforthedevice.

This ensures that the safety of the device is maintained.

If operated on

an inclined, uneven surface, liquid can escape from the tank (3) or the device

can tip over.

Donotsuckupinammableorexplosiveliquids,forexamplepetrol,oil,

The fumes or liquids can ignite or explode.

Overloading can damage the device. There is a

risk of injury.

Childrenandpersonswho,duetotheirphysical,sensoryormentalabilities

orlackofexperienceandknowledgeareunabletooperatethedevicesafely

maynotusethisdevicewithoutsupervisionorinstructionbyaresponsible

Apprentices may only operate

the device when they are older than 16, when this is necessary for their training

and under the supervision of a trained operative.

Explanationofsymbols

CAUTION Danger with a low degree of risk which could result in minor

injury (reversible) if not heeded.

NOTICE Material damage, no safety note! No danger of injury.

Read the operating manual before starting

Environmentally friendly disposal

CE conformity mark

1. Technical Data

Use for the intended purpose

CAUTION

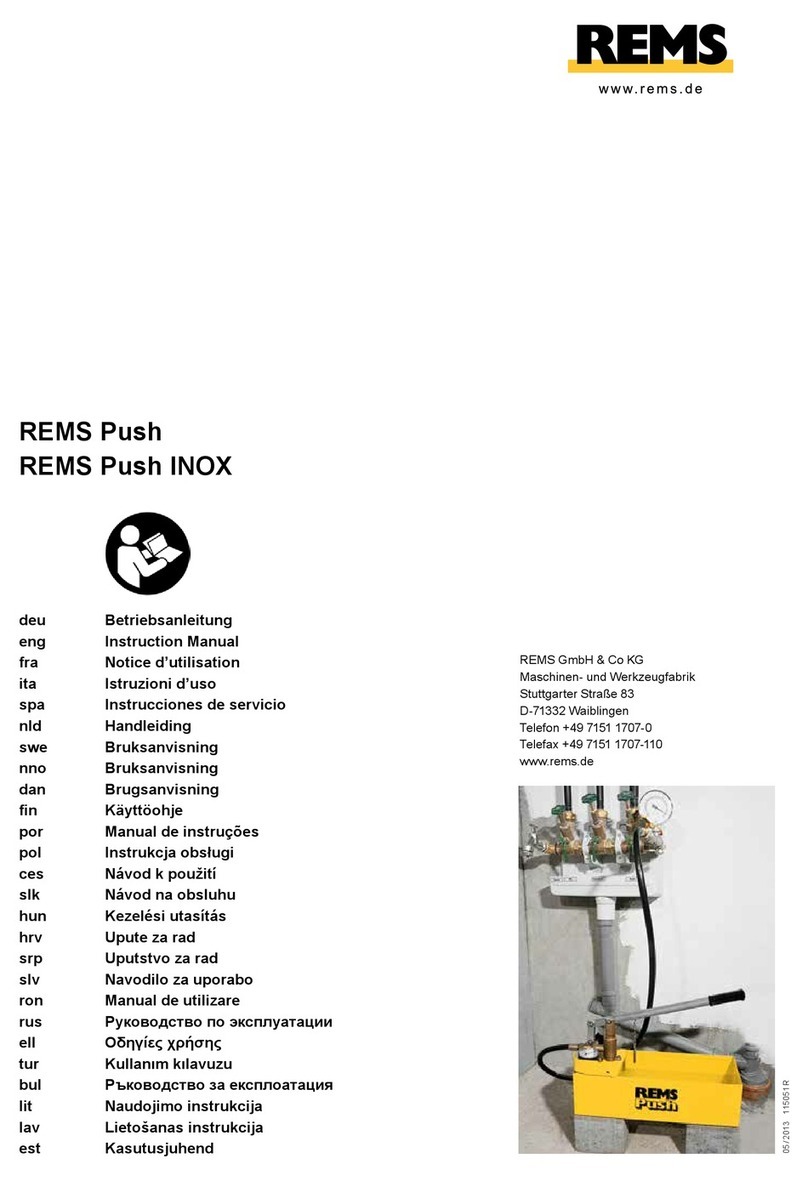

REMS Push and REMS Push INOX are designed for pressure and leak testing of

pipe systems and vessels. All other uses are not for the intended purpose and are

therefore prohibited.

NOTICE

Therespectivenationalsafetyprovisions,rulesandregulationsvalidforthe

applicationsitemustbeconsideredandobservedforproperuse.

1.1. ScopeofSupply

Hand pressure testing pump, high-pressure hose, instruction manual

1.2. Articlenumbers

REMS Push 115000

REMS Push INOX 115001

Connection piece with pressure gauge and shut-off valve 115110

Fine scaled pressure gauge 115045

REMS CleanM 140119

1.3. Workarea/dimensions/weight

Capacity of the tank 12 l

Testandpressurerange p≤6MPa/60bar/870psi

pH value of the liquids 7 – 12

Temperatureoftheliquids ≤60°C

Viscosityoftheliquids ≤1.5mPas

Dimensions REMS Push, REMS Push INOX 500 × 190 × 280 mm

Weight REMS Push, REMS Push INOX 6.9 kg

Hose connection ½"

2. Commissioning/Operation

CAUTION

Mediumunderpressurecanescapeincaseofleaks. Protect the area from

unauthorised access during pressure testing.

The hand pressure testing pump (A) is used for pressure and leak testing of

pipe systems (B), observe EN 806-4 standard and national regulations. To do

so,attachtheconnectingline(C)withpressuregauge(D)withspeciedscale

and also the shut-off valve (E) to the installed system. Close the shut-off valve

(E)andllthesystem.Connectthehigh-pressurehose(1)ofthehandpressure

testing pump to the system being tested (hose connection ½"). Open the return

valve(2),opentheshut-offvalve(E)andllthetank(3).Closethereturnvalve.

Bleed the installed system. Close the shut-off valve upstream of the installed

system(F).Setthespecied/requiredtestpressurebypumpingseveraltimes

with the pump lever (4). In the case of major differences between the ambient

temperature and the water temperature a waiting period until these temperatures

are balanced is necessary. Close the shut-off valve (E) on the installed system.

Complywiththetestingtimeasspecied.Aftercompletionofthepressuretest,

open the return valve (2). Remove the high-pressure hose from the installed

system.

Attention:Beforeconnectingthehigh-pressurehose(1),makesurethat

thepressurehasbeenrelievedcompletely.Notethepressureonthe

pressuregauge(5).

NOTICE

Donotusethehandpressuretestingpumpwithoutthesuctionlter(6).

3. Maintenance

3.1. Maintenance

Grease the pump piston from time to time. Check high-pressure hose (1) and

seals for damage before every use. Do not use a damaged high-pressure hose

anddamagedseals.Cleanthesuctionlter(6)regularly.Channgeadamaged

suctionlter.Cleanplasticparts(e.g.housing,high-pressurehose)onlywith

REMS CleanM machine cleaner (Art. No. 140119) or a mild soap and a damp

cloth. Do not use household cleaners. These often contain chemicals which

can damage the plastic parts. Never use petrol, turpentine, thinner or similar

products for cleaning.

3.2. Inspection/Repair

Thisworkmayonlybeperformedbyqualiedpersonnel.

5. Disposal

The hand pressure testing pump may not be thrown into the domestic waste

at the end of use. It must be disposed of properly by law.

6. Manufacturer’sWarranty

The warranty period shall be 12 months from delivery of the new product to the

rstuser.Thedateofdeliveryshallbedocumentedbythesubmissionofthe

original purchase documents, which must include the date of purchase and the

designation of the product. All functional defects occurring within the warranty

period, which are clearly the consequence of defects in production or materials,

will be remedied free of charge. The remedy of defects shall not extend or

renew the warranty period for the product. Damage attributable to natural wear

and tear, incorrect treatment or misuse, failure to observe the operational

instructions, unsuitable operating materials, excessive demand, use for unau-

thorized purposes, interventions by the customer or a third party or other

reasons, for which REMS is not responsible, shall be excluded from the warranty

Services under the warranty may only be provided by customer service stations

authorized for this purpose by REMS. Complaints will only be accepted if the

product is returned to a customer service station authorized by REMS without

prior interference in an unassembled condition. Replaced products and parts

shall become the property of REMS.

The user shall be responsible for the cost of shipping and returning the product.

The legal rights of the user, in particular the right to make claims against the

seller under the warranty terms, shall not be affected. This manufacturer’s

warranty only applies for new products which are purchased in the European

Union, in Norway or in Switzerland.

This warranty is subject to German law with the exclusion of the United Nations

Convention on Contracts for the International Sales of Goods (CISG).

7. Sparepartslists

For spare parts lists, see www.rems.de→Downloads→Partslists.

eng eng

4. Faults

4.1. Fault: The desired test pressure is not reached.

Cause:

●

Suctionlter(6)isblocked.

●

Cleansuctionlter,changeifnecessary.

●

Return valve (14) does not close

●

Clean return valve and seal seat, change return valve if necessary.

●

O-ring on pump piston damaged.

●

Hand pressure testing pump sucks in air.

●

Checkwater/liquidlevelinthetank(3),llupifnecessary.

●

Installed system leaking.

●

Shut-off valve (F) not closed.

●

Hand pressure testing pump defective.

●

Have the hand pressure testing pump checked/repaired by an authorised

REMS customer service workshop.

4.2. Fault: Test pressure is not held.

Cause:

●

Shut-off valve (E) and/or (F) not closed.

●

Installed system leaking.

●

Hand pressure testing pump defective.

●

Close shut-off valve (E). Have the hand pressure testing pump checked/

repaired by an authorised REMS customer service workshop.

4.3. Fault: Pump lever (4) rises.

Cause:

●

Ball of the pump on pressure side does not close.

●

Clean ball and ball seat, change ball if necessary.

●

Hand pressure testing pump defective.

●

Have the hand pressure testing pump checked/repaired by an authorised

REMS customer service workshop.

6

The hand pressure testing pump may not be thrown into the domestic waste

at the end of use. It must be disposed of properly by law.

6. Manufacturer’sWarranty

The warranty period shall be 12 months from delivery of the new product to the

rstuser.Thedateofdeliveryshallbedocumentedbythesubmissionofthe

original purchase documents, which must include the date of purchase and the

designation of the product. All functional defects occurring within the warranty

period, which are clearly the consequence of defects in production or materials,

will be remedied free of charge. The remedy of defects shall not extend or

renew the warranty period for the product. Damage attributable to natural wear

and tear, incorrect treatment or misuse, failure to observe the operational

instructions, unsuitable operating materials, excessive demand, use for unau-

thorized purposes, interventions by the customer or a third party or other

reasons, for which REMS is not responsible, shall be excluded from the warranty

Services under the warranty may only be provided by customer service stations

authorized for this purpose by REMS. Complaints will only be accepted if the

product is returned to a customer service station authorized by REMS without

prior interference in an unassembled condition. Replaced products and parts

shall become the property of REMS.

The user shall be responsible for the cost of shipping and returning the product.

The legal rights of the user, in particular the right to make claims against the

seller under the warranty terms, shall not be affected. This manufacturer’s

warranty only applies for new products which are purchased in the European

Union, in Norway or in Switzerland.

This warranty is subject to German law with the exclusion of the United Nations

Convention on Contracts for the International Sales of Goods (CISG).

7. Sparepartslists

For spare parts lists, see www.rems.de→Downloads→Partslists.

eng eng

4. Faults

4.1. Fault: The desired test pressure is not reached.

Cause: Remedy:

●

Suctionlter(6)isblocked.

●

Cleansuctionlter,changeifnecessary.

●

Return valve (14) does not close

●

Clean return valve and seal seat, change return valve if necessary.

●

O-ring on pump piston damaged.

●

Change O-ring.

●

Hand pressure testing pump sucks in air.

●

Checkwater/liquidlevelinthetank(3),llupifnecessary.

●

Installed system leaking.

●

Seal installed system.

●

Shut-off valve (F) not closed.

●

Close shut-off valve.

●

Hand pressure testing pump defective.

●

Have the hand pressure testing pump checked/repaired by an authorised

REMS customer service workshop.

4.2. Fault: Test pressure is not held.

Cause: Remedy:

●

Shut-off valve (E) and/or (F) not closed.

●

Close shut-off valve.

●

Installed system leaking.

●

Seal installed system.

●

Hand pressure testing pump defective.

●

Close shut-off valve (E). Have the hand pressure testing pump checked/

repaired by an authorised REMS customer service workshop.

4.3. Fault: Pump lever (4) rises.

Cause: Remedy:

●

Ball of the pump on pressure side does not close.

●

Clean ball and ball seat, change ball if necessary.

●

Hand pressure testing pump defective.

●

Have the hand pressure testing pump checked/repaired by an authorised

REMS customer service workshop.

5. Disposal

The hand pressure testing pump may not be thrown into the domestic waste

at the end of use. It must be disposed of properly by law.

6. Manufacturer’sWarranty

The warranty period shall be 12 months from delivery of the new product to the

rstuser.Thedateofdeliveryshallbedocumentedbythesubmissionofthe

original purchase documents, which must include the date of purchase and the

designation of the product. All functional defects occurring within the warranty

period, which are clearly the consequence of defects in production or materials,

will be remedied free of charge. The remedy of defects shall not extend or

renew the warranty period for the product. Damage attributable to natural wear

and tear, incorrect treatment or misuse, failure to observe the operational

instructions, unsuitable operating materials, excessive demand, use for unau-

thorized purposes, interventions by the customer or a third party or other

reasons, for which REMS is not responsible, shall be excluded from the warranty

Services under the warranty may only be provided by customer service stations

authorized for this purpose by REMS. Complaints will only be accepted if the

product is returned to a customer service station authorized by REMS without

prior interference in an unassembled condition. Replaced products and parts

shall become the property of REMS.

The user shall be responsible for the cost of shipping and returning the product.

The legal rights of the user, in particular the right to make claims against the

seller under the warranty terms, shall not be affected. This manufacturer’s

warranty only applies for new products which are purchased in the European

Union, in Norway or in Switzerland.

This warranty is subject to German law with the exclusion of the United Nations

Convention on Contracts for the International Sales of Goods (CISG).

7. Sparepartslists

For spare parts lists, see www.rems.de→Downloads→Partslists.

eng eng

4. Faults

4.1. Fault: The desired test pressure is not reached.

Cause:

Remedy:

●

Suctionlter(6)isblocked.

●

Cleansuctionlter,changeifnecessary.

●

Return valve (14) does not close

●

Clean return valve and seal seat, change return valve if necessary.

●

O-ring on pump piston damaged.

●

Change O-ring.

●

Hand pressure testing pump sucks in air.

●

Checkwater/liquidlevelinthetank(3),llupifnecessary.

●

Installed system leaking.

●

Seal installed system.

●

Shut-off valve (F) not closed.

●

Close shut-off valve.

●

Hand pressure testing pump defective.

●

Have the hand pressure testing pump checked/repaired by an authorised

REMS customer service workshop.

4.2. Fault: Test pressure is not held.

Cause:

Remedy:

●

Shut-off valve (E) and/or (F) not closed.

●

Close shut-off valve.

●

Installed system leaking.

●

Seal installed system.

●

Hand pressure testing pump defective.

●

Close shut-off valve (E). Have the hand pressure testing pump checked/

repaired by an authorised REMS customer service workshop.

4.3. Fault: Pump lever (4) rises.

Cause:

Remedy:

●

Ball of the pump on pressure side does not close.

●

Clean ball and ball seat, change ball if necessary.

●

Hand pressure testing pump defective.

●

Have the hand pressure testing pump checked/repaired by an authorised

REMS customer service workshop.