Troubleshooting

Fault Possible cause Solution

Lid failing

to close

Guideway

obstructed.

Spring failure.

Examing the guideway and remove any

obstruction.

Examine the springs and ensure that they

are connected to the respective holding

pins within the assembly.

If a spring has failed, or is missing, spring

replacement kits are available from your

local Renishaw company or supplier.

Alternatively, return the unit to your local

Renishaw service centre to have new

springs fitted.

Failure to

complete

a stylus

change

Incorrect

alignment.

Re-align the MRS rail (refer to the MRS

modular rack system installation and

user’s guide, Renishaw part number

H-1000-5088).

Redatum the SCP600 port.

Accessories / spare parts

SCP600 port (includes tooling) A-2098-0933

T nut P-NU18-0005

Stylus spanner M-5000-3707

Put down and pick up routines

NOTE: The following section assumes that the datum created in ‘Datuming

the SCP600’ earlier in this document is the axis system in which the machine

is working.

Put down routine

The following table lists the recommended procedure for putting down a

stylus module on the SCP600. All dimensions are absolute and given in mm.

Operation Axis position

X axis Y axis Z axis

Inhibit the probe

Move to stand-off position 0 50 0

Move into port 0 0 0

Detach stylus module 0 0 8

Move to stand-off position 0 50 8

Pick up routine

The following table lists the recommended procedure for picking up a stylus

module from the SCP600. All dimensions are absolute and given in mm.

Operation Axis position

X axis Y axis Z axis

Move to stand-off position 0 50 8

Move into port 0 0 8

Attach stylus module 0 0 0

Move to stand-off position 0 50 0

Activate probe

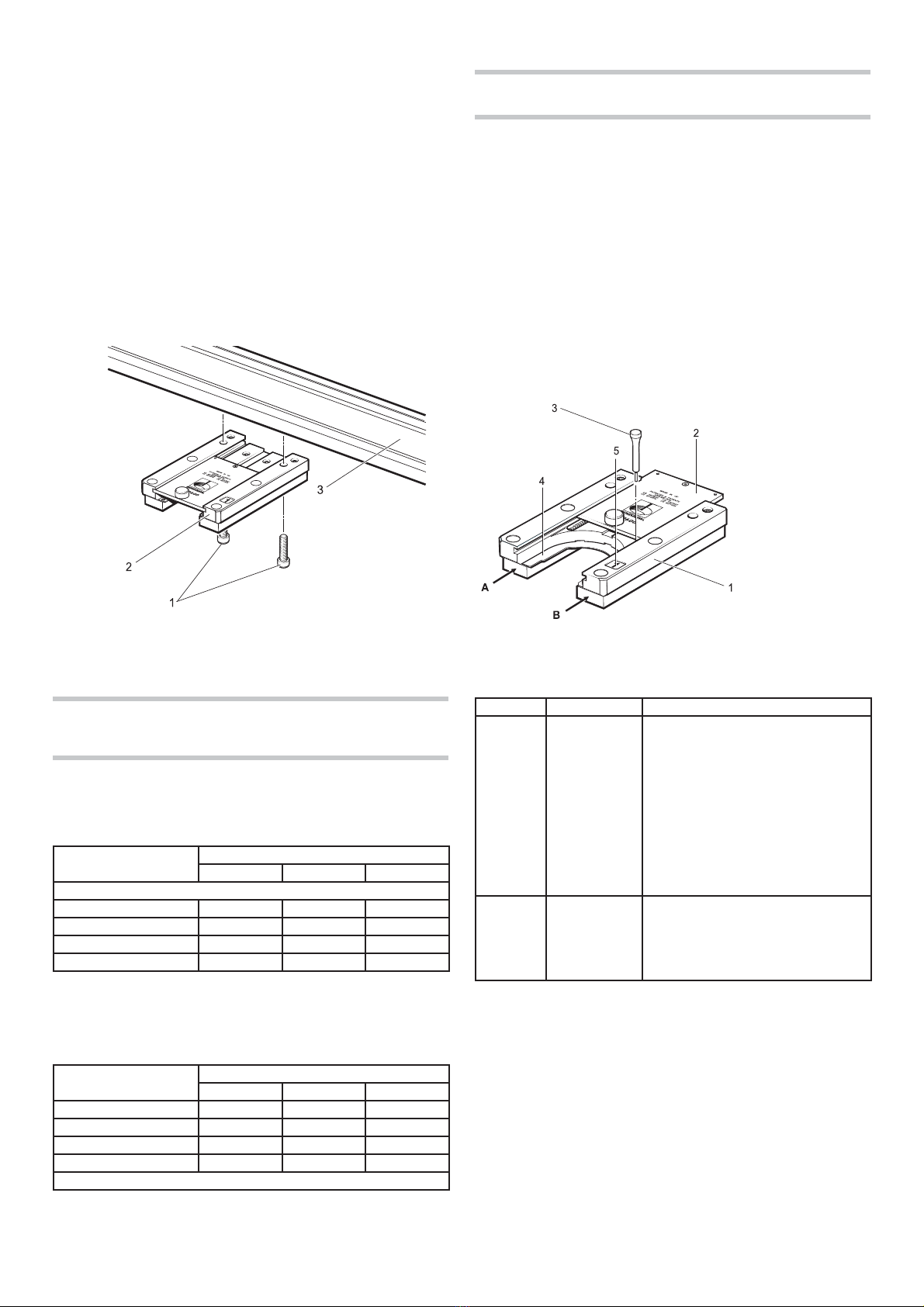

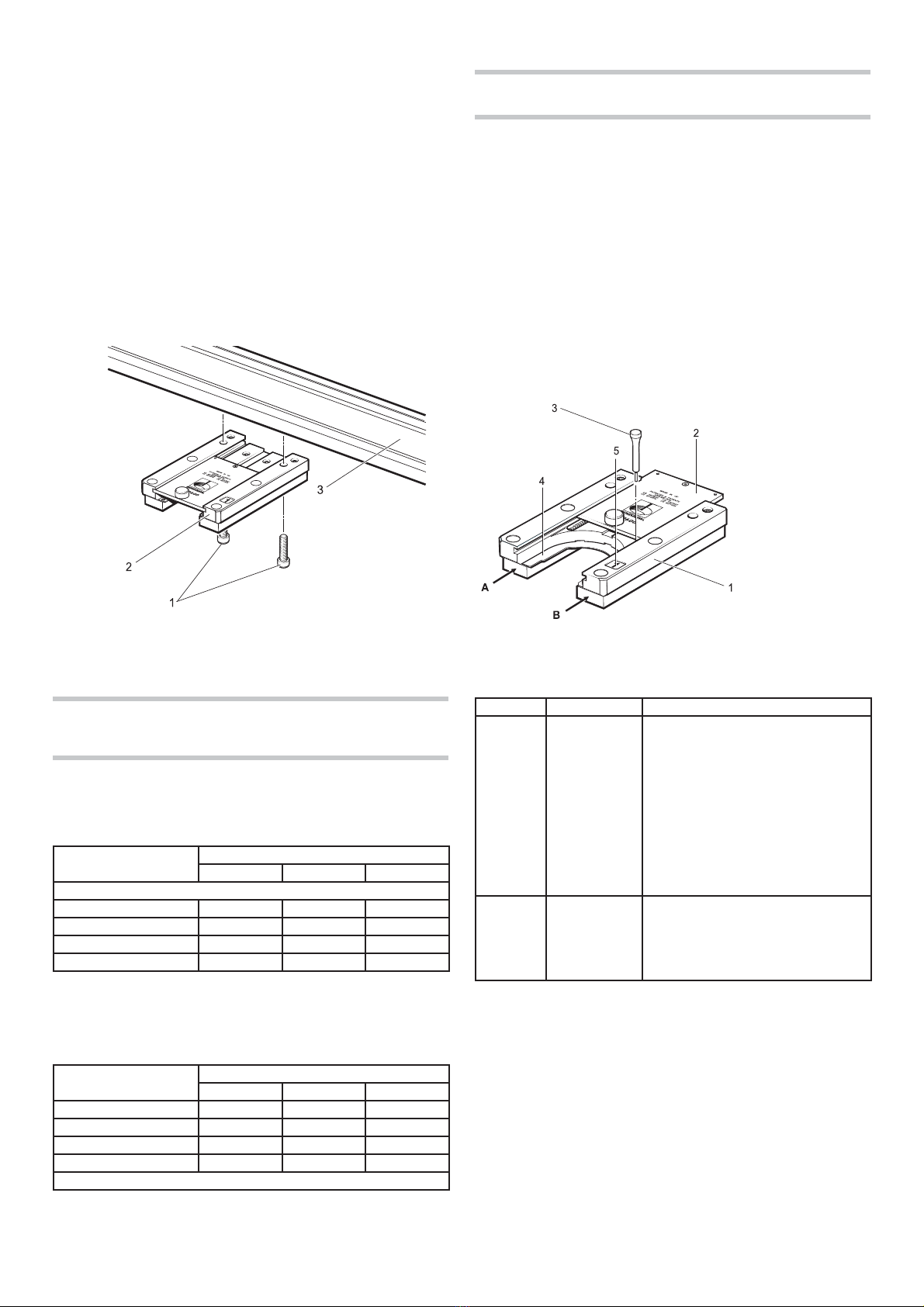

1. Fixing screw

2. SCP600 port

3. MRS rail

Figure 2 - Fitting a SCP600 port to the MRS rail

Datuming the SCP600

NOTE: As the SCP600 port is of modular design, it is suggested that the

following routine is completed under manual control for each port installed.

The following section describes the recommended procedure for datuming

the SCP600 once it is fitted to the MRS rail and on the CMM table. In

addition, the following method assumes that the SCP600 port is aligned to

the CMMs axis with a maximum run out of 2.5 mm across points A and B

(see figure 3). If required, please refer to ‘Fitting the SCP600 to the MRS rail’

earlier in this document. The recommended procedure to locate the port is

as given below (please refer to figure 3):

1. Push the lid [2] of the SCP600 port [1] to the extreme of travel (this

assumes that the SCP600 is connected to the MRS system at the time).

2. Place the stylus tool [3] into the retaining hole at the rear of the

SCP600 port [1].

3. Release the SCP600 lid [2] so that the stylus tool [3] holds the lid.

4. Take 4 points on the top face of the docking plate [4] (plane 1).

5. Take 4 points in the circle at the rear of the SCP600 port docking

plate [4] (circle 1).

Figure 3 - Datuming the SCP600 port

1. SCP600

2. Lid

3. Stylus tool

4. Docking plate

5. Port

identification

label

Fitting the SCP600 to the MRS rail

It is recommended that the SCP600 ports are attached to the MRS rail using

the following procedure where it is assumed that the MRS system is correctly

installed. For full details, please refer to the MRS modular rack system

installation and user’s guide (H-1000-5088):

1. Insert one of the fixing screws [1] through the SCP600 port [2] as

shown in figure 2.

2. Offer up the SCP600 port [2] to the MRS rail [3], positioning the fixing

screw [1] to the respective ‘T’ bolt within the rail. Finger-tighten the

screw.

3. Insert the other fixing screw [1] through the SCP600 port [2] as shown

in figure 2.

4. Position the SCP600 port so that the second screw locates into the

respective ‘T’ bolt in the rail. Finger-tighten the screw.

5. Using the hexagonal key supplied, hand-tighten the two fixing screws

[1] into the ‘T’ bolts.