Introduction

4

DocNo: UMAN\GWY-500-B\0106

REVISION4

1.3 GWY-500 Specifications

Power : 24 V DC, 2.5 W

LED’s : 3 LED’s for status indication

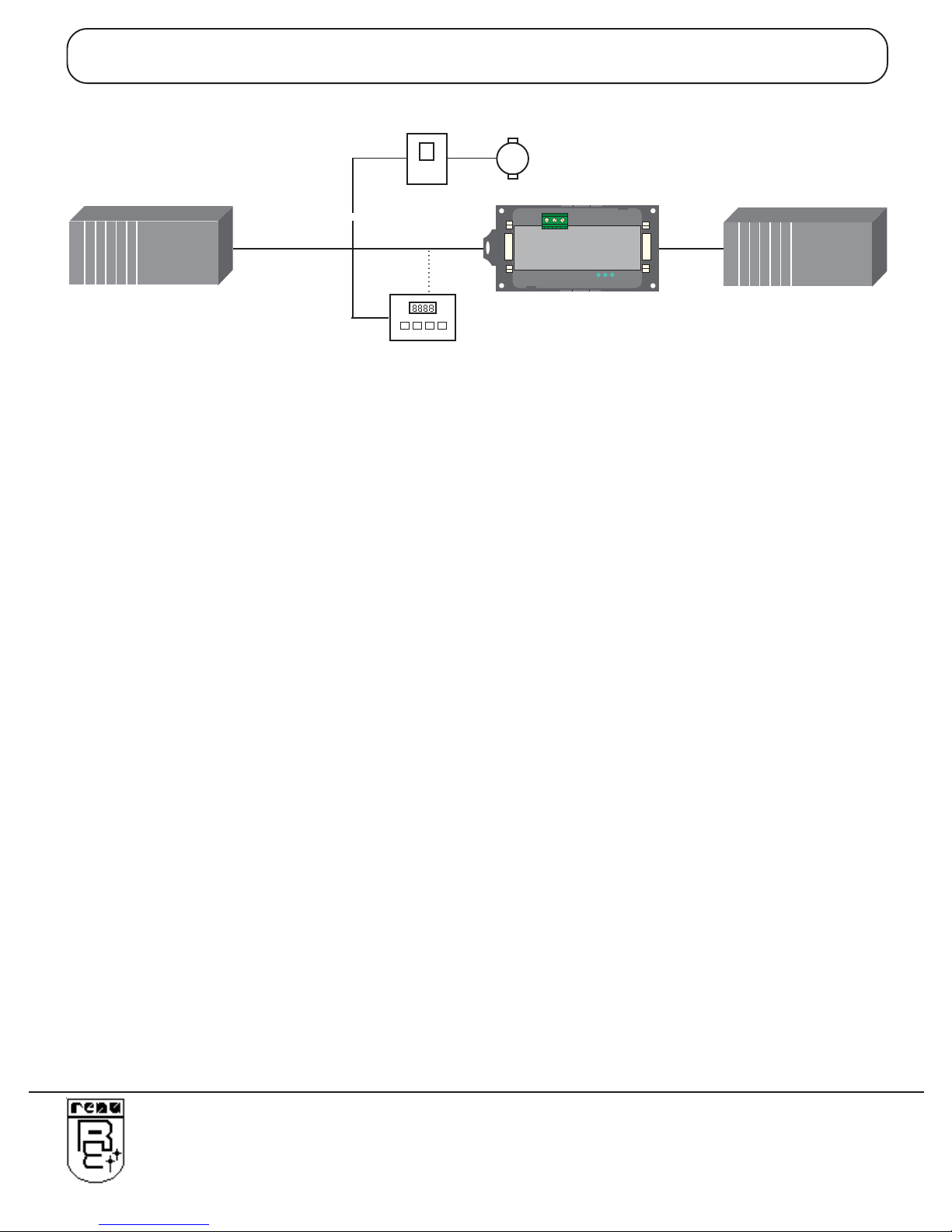

CommunicationPorts : 2Communication portswith

COM1 : RS232 / RS422 / RS485 / CMOS

COM2 : Profibus-DPV0Slave (2 WireRS485)

(Isolationbetween communicationports andPower supply, through DC-DC coupler is 1 KV)

COM1 /PLC1 : Connects to PC for setup download or connects to PLC1 at runtime.

COM2/ PLC2 : Profibus-DPV0Slave (2Wire RS485)

(Isolationbetween communication ports, through opto-isolationis 1KVrms for 1 min)

ProfibusBaudRate : 9.6k, 19.2k, 45.45k, 93.75k, 187.5k, 500k, 1.5M, 3M, 6M, 12M Bit/s

(Autodetect)

GSDFile : Suppliedin the InstallableSoftware CD.

GSDFile Name : RENU0A0E.GSD

I/Odata : 100Word Input, 100 WordOutput

*Profibus SlaveID : 0 - 125(ID shouldbe providedthrough GatewaySetup Software/PLC2

Settings/Advanced)

OperatingTemperature : 0oto 60oC

StorageTemperature : -20oto 80oC

Humidity : 10%to 90%(Non condensing)

Mounting : DINrail orback panelmounting

Dimensions(DINrail) : 105mm(L)X40mm(D) X51mm(W)

Weight : 125gm approx.

Certifications : CE with UL certification

Immunity to ESD : Level3asper IEC1000-4-2

Immunityto Transients : Level3asper IEC1000-4-4

Immunityto RadiatedRF : Level3asperIEC1000-4-3

Immunityto ConductedRF : Level 3asperIEC1000-4-6

Emissions : EN55011CISPRA

Note1 : If Toshiba VF-S11 Inverter is connected at COM1 of GWY-500, station number is detected automatically at

power ON and that station number is assigned as a Profibus Slave ID.

InverterID Canbe setfrom 0-99.

Note2 : Once You install Gateway Setup Software, you will find GSD file at:

“C:\Program Files\Gateway3.XX\GWY-5oo(Profibus Gateway)\GSD”. Thisis the defaultpath.Theactual pathis

wherethe user hasinstalled Gateway SetupSoftware.

Note3 : GSD file is also provided in the CD along with the Installable software.

Note4 : Previously the model name in GSD file was GWY-500 Now it is changed to GWY-XXXXX to support all the

productshaving Profibusport.

Note5 : Profibus detects baud rate automatically. So baud rate field in PLC2 Settings of Gateway software does not

havemeaning specificmeaning.

Source ID and Destination ID related to Profibus driver does not have specific meaning. Profibus ID is set by

Gatewayconfiguration software.(PLC2 settings/Advanced).