Pace C 07, C 09, C 11

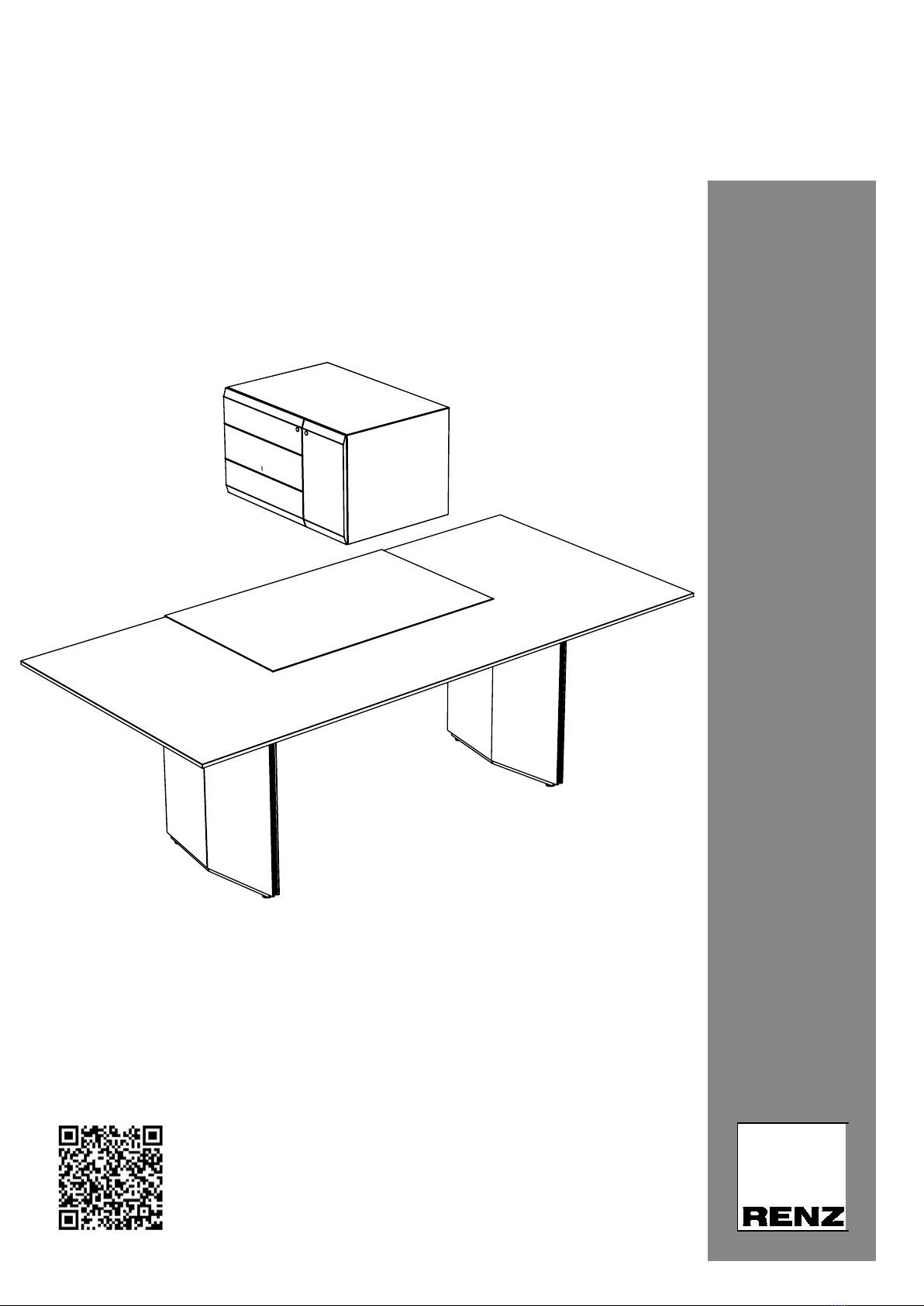

Tisch-Montage/Table assembly

Aufbau/Assembly

(Es werden 2 Personen benötigt/Two people are required.):

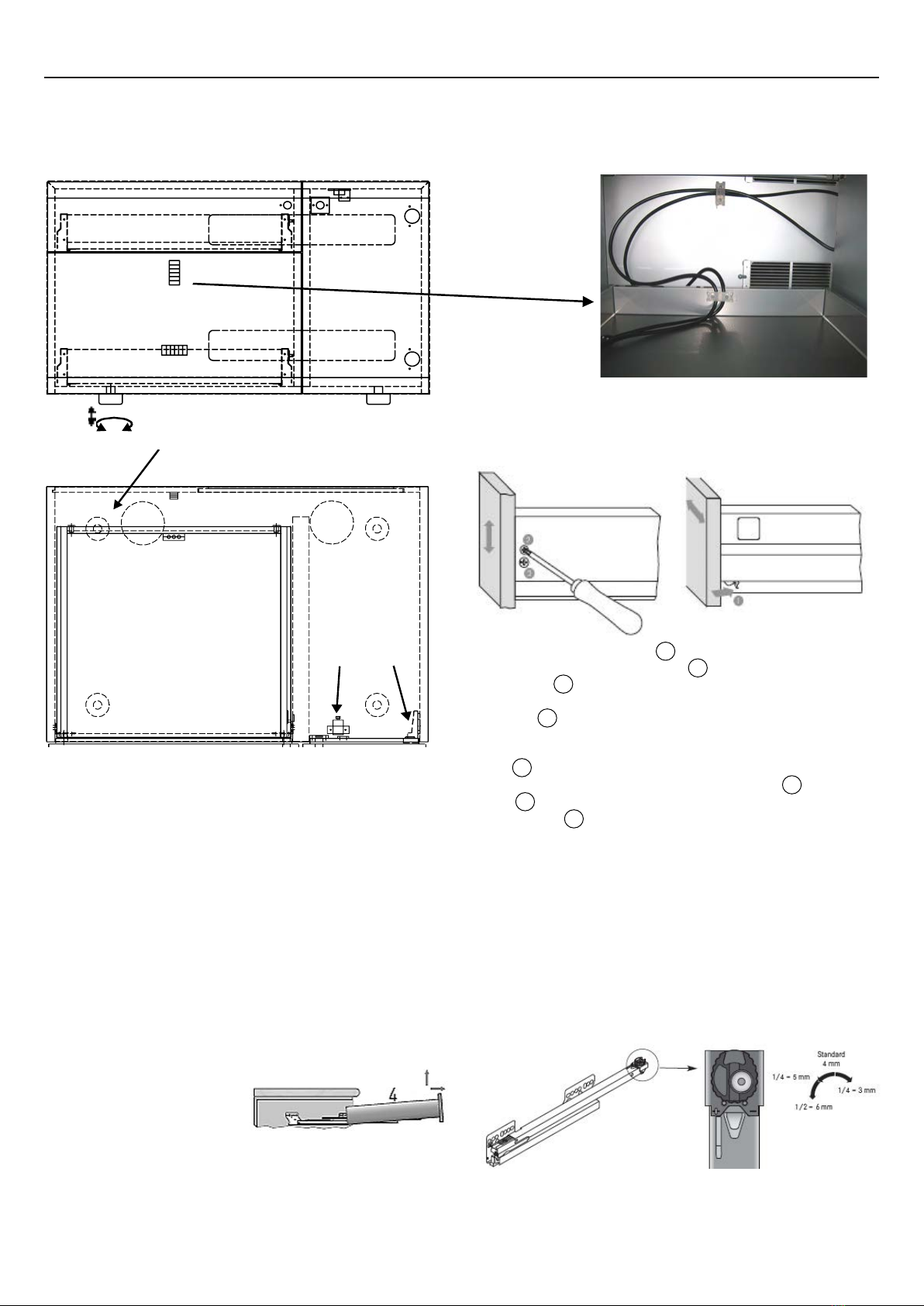

Kontrollieren Sie vor der Montage, dass Elektrokabel, Isolierungen und Bauteile nicht beschädigt sind. Bei Beschädi-

gungen darf das System nicht an das Stromnetz angeschlossen werden!

Check electric cables, isolations and components for intactness before assembly. In case of damage the system must not

be connected to the electric grid!

1.

Wangen und Gestell ausrichten: „Roter Punkt zu rotem Punkt“

= markiert hintere Tischkante.

- Zargenrahmen beidseitig mit je 5 Stück M10 x 20 Zylinder-

kopf fest verschrauben. (WICHTIG: Unterlegscheiben ver-

wenden).

- Kabelausgang oben: Kabelbaum nach unten durch den

Traversenrahmen führen.

1.

Align panels and rack: „Red point to red point“ = marks the rear

edge.

- Screw cross piece frameworks tightly on both sides with 5 pieces

M10 x 20 cylinder head screws. (IMPORTANT: Only screw with

washer).

- Cable exit on top: Place the cable tree downwards through the

cross-rail frame.

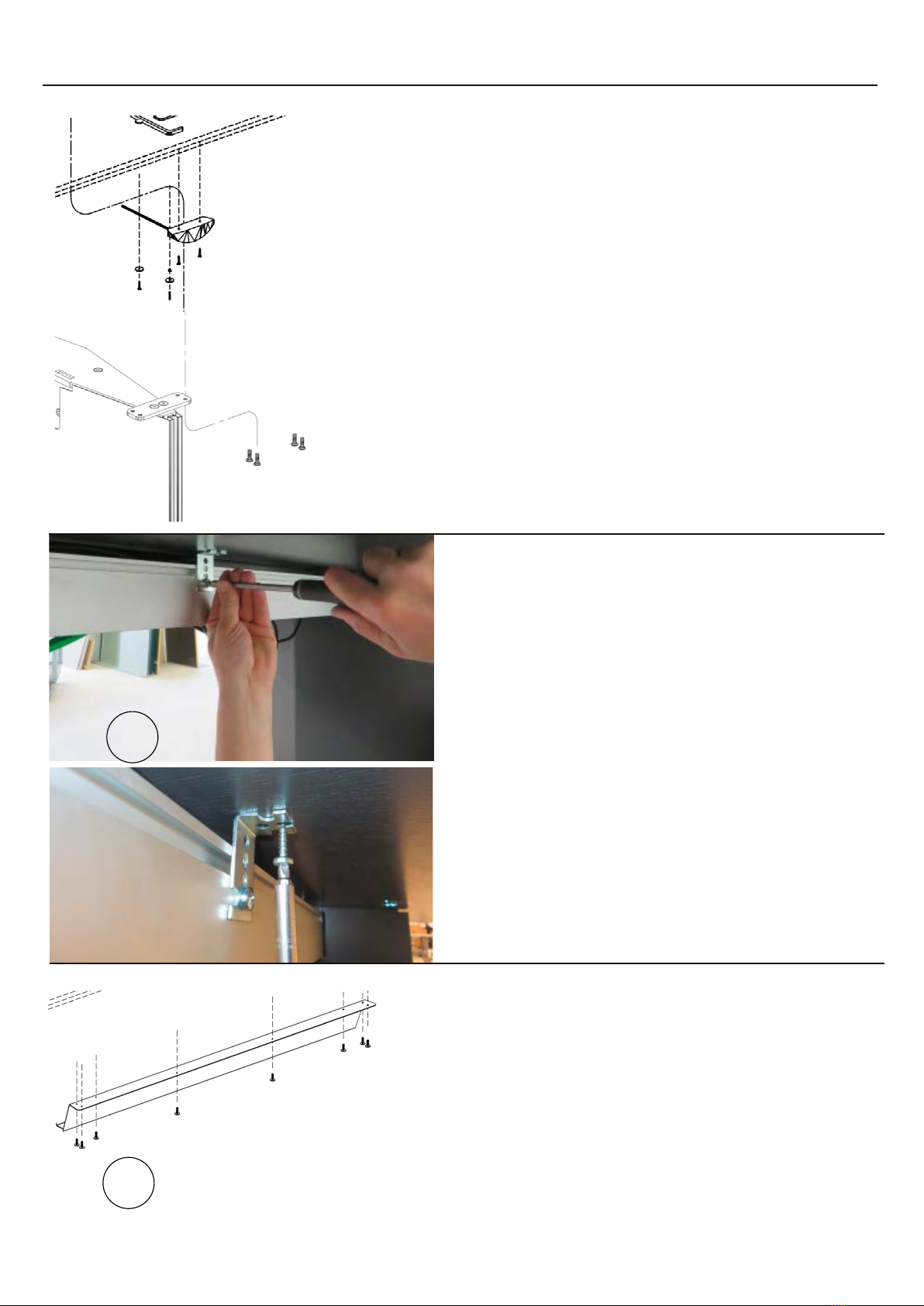

2.

Gestell nach bauseitiger Elektrozuführung („V1“ oder „V2“)

ausrichten.

- Für Anschluss der Datenkabel mit min. 2 Personen das

Tischgestell um ca. 30 Grad ankippen (nicht umlegen),

bauseitige Kabel von unten einstecken.

- Gestell vorsichtig zurückkippen, Anschlusskabel sauber

verlegen.

- Wenn Kabel auf dem Boden verlegt werden („V2“), müssen

diese in fest montierten Boden-Installationskanälen geführt

sein. Kabel nicht knicken und nur gemäß Herstellervorgaben

biegen.

2.

Align frame to the electrical on-site connection („V1“ or „V2“).

- For connecting data cables cant the table frame to about 30

degrees with min. 2 people (do not overturn), plug the on-site

cables from the bottom.

- Cant the frame gently back and lay the connection cable

neatly.

- Cables laid above floor cover(„V2“), have to be run in perma-

nently installed floor canals. Do not fold the cable and bend it

only in accordance with manufacturer‘s specifications.

1.

L/R Je 5 Stück

M10x20 mm

Zylinderkopf mit

Unterlegscheibe.

L/R Each 5 pieces

M10x20 mm

cylinder head with

washer.

„V2“ Bauseitige Kabel

über Belag nur in

festem Kanal verlegt.

„V2“ On-site cabling

above floor cover th-

rough/in canal.

„V1“Bauseitige Kabel

von unten aus dem

Bodentank kommend.

„V1“ On-site cabling

from below out of floor

tank.

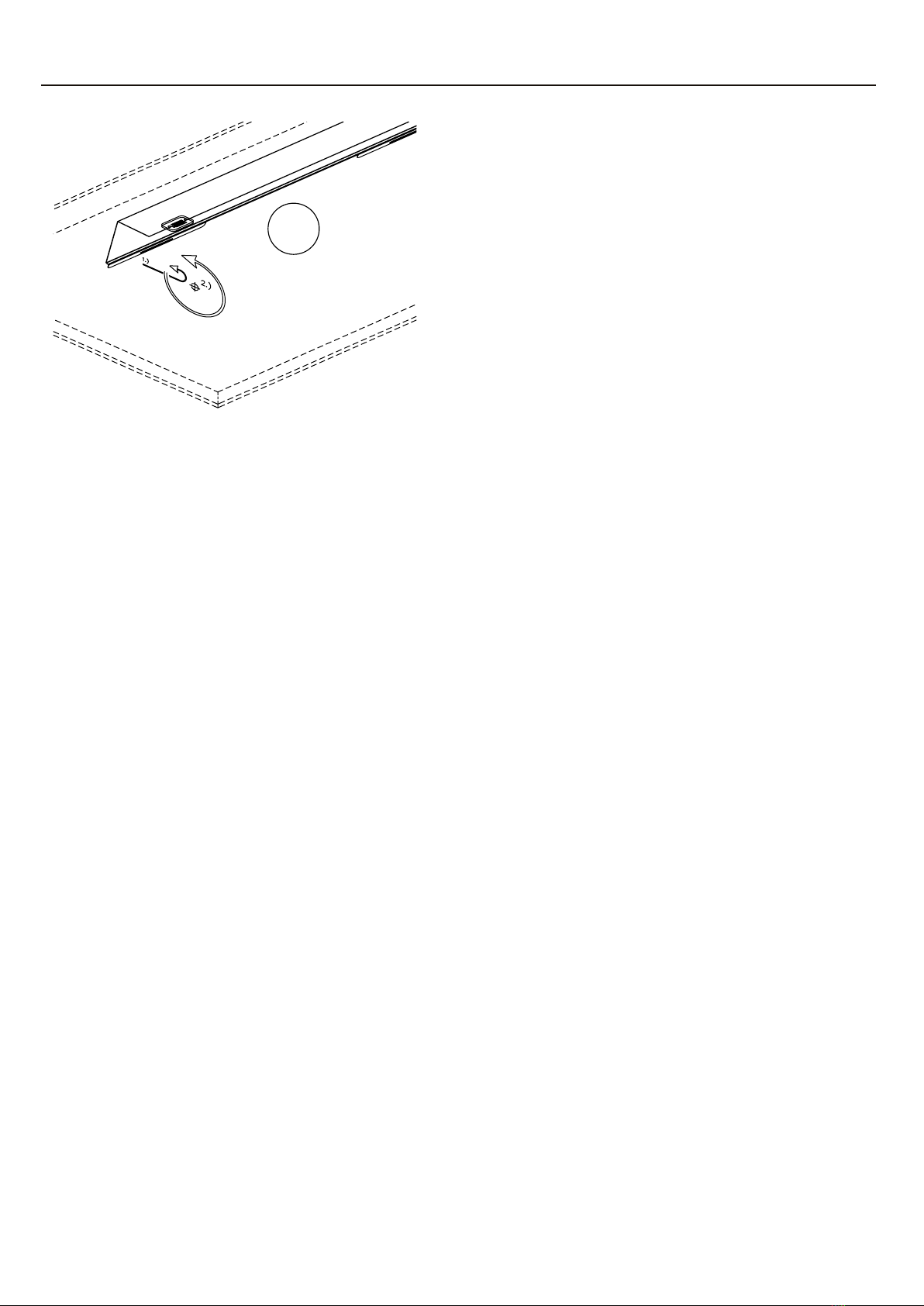

2.