9

en

4 Non-return valve

The non-return valve is located above the pump in the return line.

5 Maintenance

In order to remove limescale, we recommend cleaning the heating element and the

throttle orice annually.

ATTENTION! Damage caused by improper cleaning uids!

Using cleaning uids not suited for high-grade steel, copper or

nickel can damage the heating element!

ÎUse cleaning uids according to the manufacturer’s

instructions only.

For the cleaning uid, use chloride-free or low-chloride water

with low hardness.

Cleaning the heating element

In order to clean the heating element, carry out the following steps:

ÎRemove the heating element.

ÎFlush the heating element with appropriate cleaning uid against the normal

ow direction.

ÎFlush the cleaned heating element and the system with clear water.

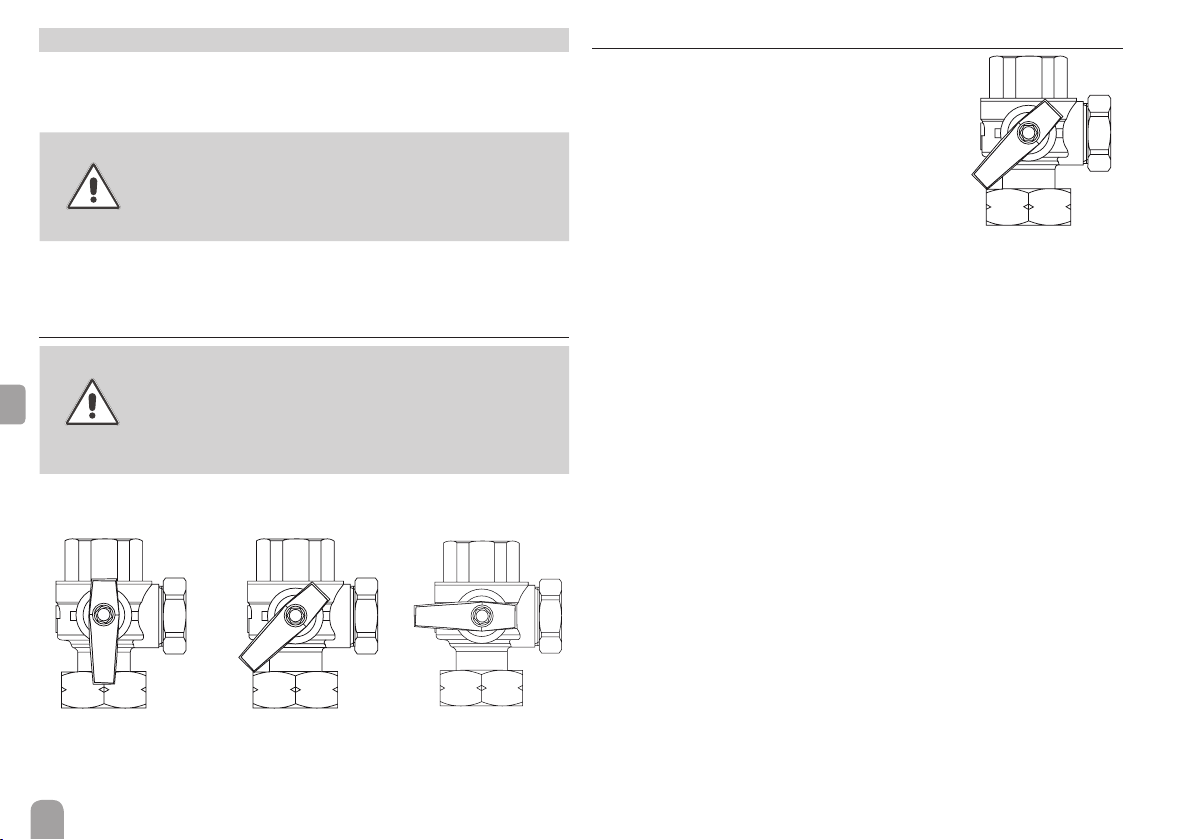

Cleaning the throttle orice

ÎIn order to clean the throttle orice, close both ball valves.

A B

ÎRemove the lateral cover (A) at the ball valve in the ow and clean the throttle

orice (B).

6 Troubleshooting

If an error has occurred, it will be indicated on the controller screen.

Please pay attention to the controller manual!

Fault condition Possible cause Elimination

Pump noise Air inside the system Vent the system

Flow rate too low

(ΔT too high)

Water pressure too low Check and increase pressure

if necessary

Heat exchanger calcied Decalcication / replacement

Throttle orice polluted Clean throttle orice, see

maintenance

Non-return valve blocked

(error message = red LED at

pump head)

Control pump at 10% speed

in manual operation

Target tempera-

ture not reached

Incorrect controller adjust-

ment

Check adjustments

Heating element

does not heat

Controller not in operation Check controller

Temperature sensor not cor-

rectly connected or defective

Check or replace, if necessary

Pump defective Check or replace, if necessary

Thermal cut-out triggered Reset (below black cover in

DeltaTherm®E Power)