Safety advice

Please pay attention to the following

safety advice in order to avoid danger

and damage to people and property.

This product is to be used in accor-

dance with its intended use only (see

page 3).

Instructions

Attention should be paid to

- the statutory provisions for preven-

tion of industrial accidents,

- the statutory provisions for environ-

mental protection,

- the Health and Safety at Work Act

1974

- Part P of the Building Regulations

2005

- BS7671 Requirements for electrical

installations and relevant safety re-

gulations of DIN, EN, DVGW,TRGI,

TRF and VDE.

These instructions are exclusively

addressed to authorised skilled per-

sonnel.

- Only qualified electricians should

carry out electrical works.

- Initial installation must be effected

by qualified personnel named by the

manufacturer

Declaration of conformity

We, RESOL Elektronische Regelungen GmbH, D-45527 Hattingen, declare un-

der our sole responsibility that our product WMZ complies with the following

standards:

EN 55 014-1

EN 60 730-1

According to the regulations of the above directives, the product is labelled with

:

89/336/EWG

73/ 23/EWG

Hattingen, 19.02.2007

RESOL Elektronische Regelungen GmbH,

ppa. Gerald Neuse

Table of contents

Safety advice.............................................................................................2

Technical data and functions...................................................................3

1. Installation........................................................................................... 5

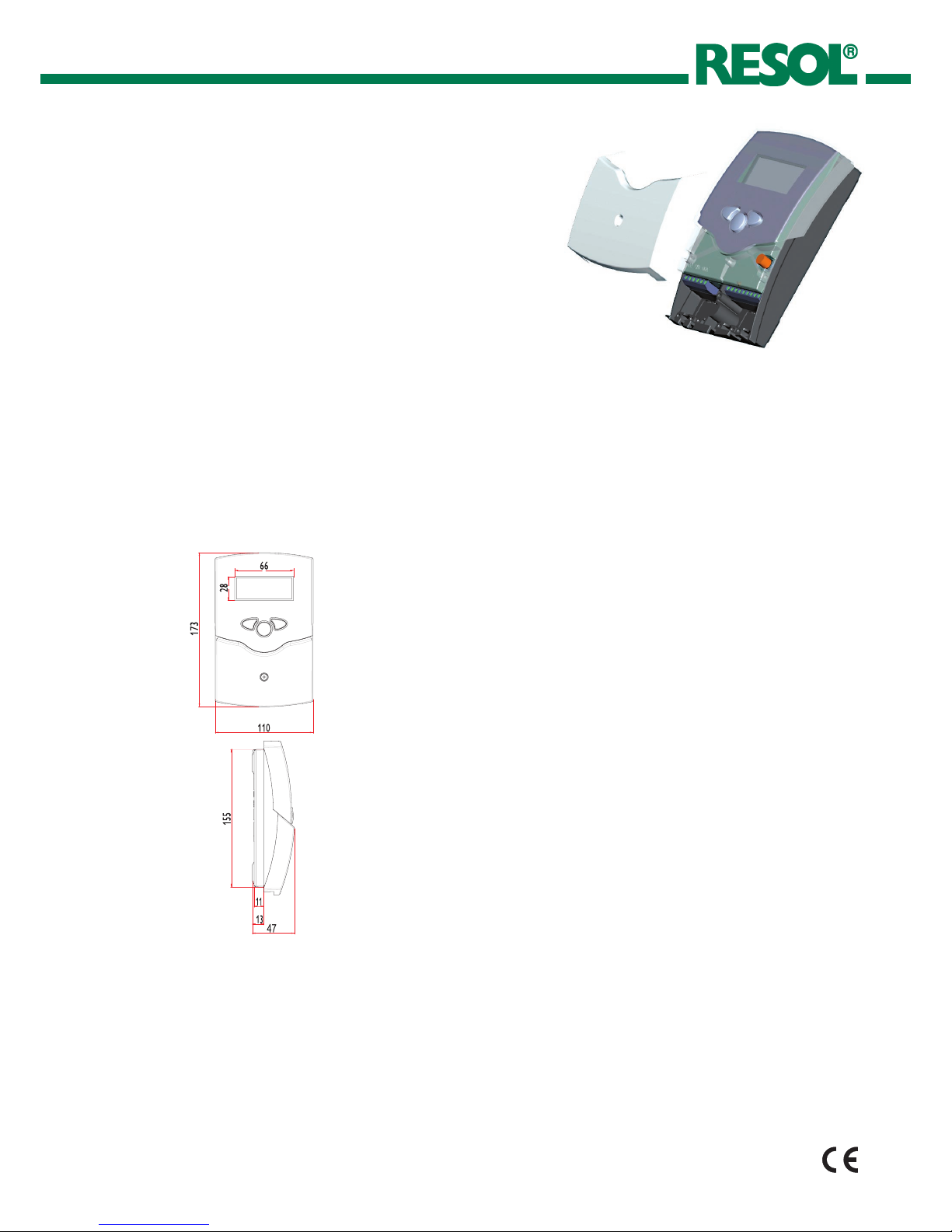

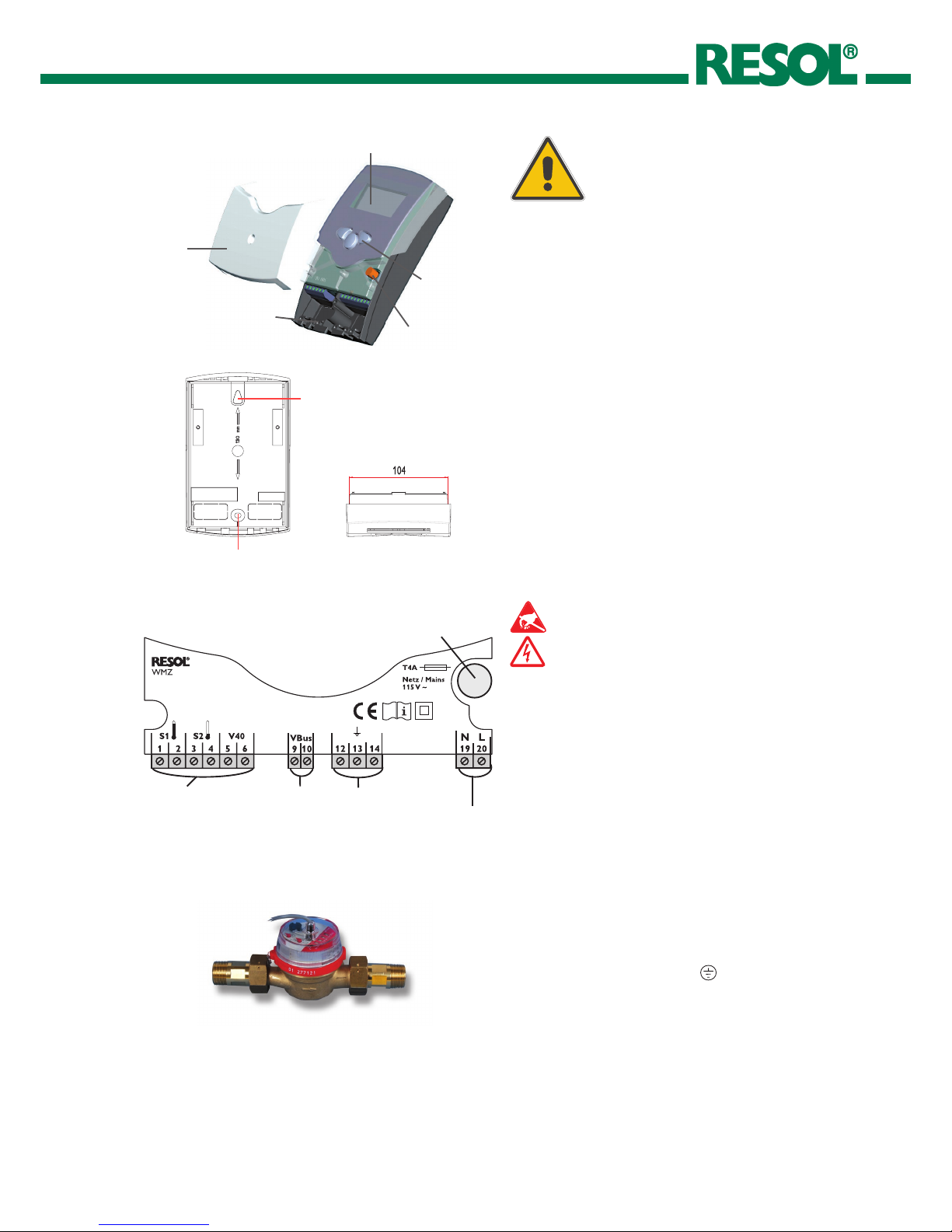

1.1 Mounting......................................................................................................5

1.2 Electrical connection.................................................................................5

1.3 Flowmeter ...................................................................................................5

2. Operation and function .....................................................................6

2.1 Buttons for adjustment.............................................................................6

2.2 Graphic display ...........................................................................................6

2.3 LED flashing codes.....................................................................................6

3. Determining the glycol-water ratio..................................................7

4. Function............................................................................................... 7

5. Indication and adjustment channels.................................................8

5.1 Heat quantity ..............................................................................................8

5.2 Flow and return temperatures ...............................................................8

5.3 Volumetric flow rate .................................................................................8

5.4 Power ...........................................................................................................8

5.5 Antifreeze type...........................................................................................9

5.6 Antifreeze ratio..........................................................................................9

5.7 Flowmeter ...................................................................................................9

5.8 Volume/Impulse ..........................................................................................9

5.9 Subaddress...................................................................................................9

5.10 Bus mode...................................................................................................10

5.11 Bus master.................................................................................................10

5.12 Sensor offset .............................................................................................10

5.13 Reset...........................................................................................................10

5.13 Language.....................................................................................................10

6. Examples of connection................................................................... 11

7. Tips for trouble shooting .................................................................12

Imprint ..............................................................................................16

Errors an technical changes excepted.