English

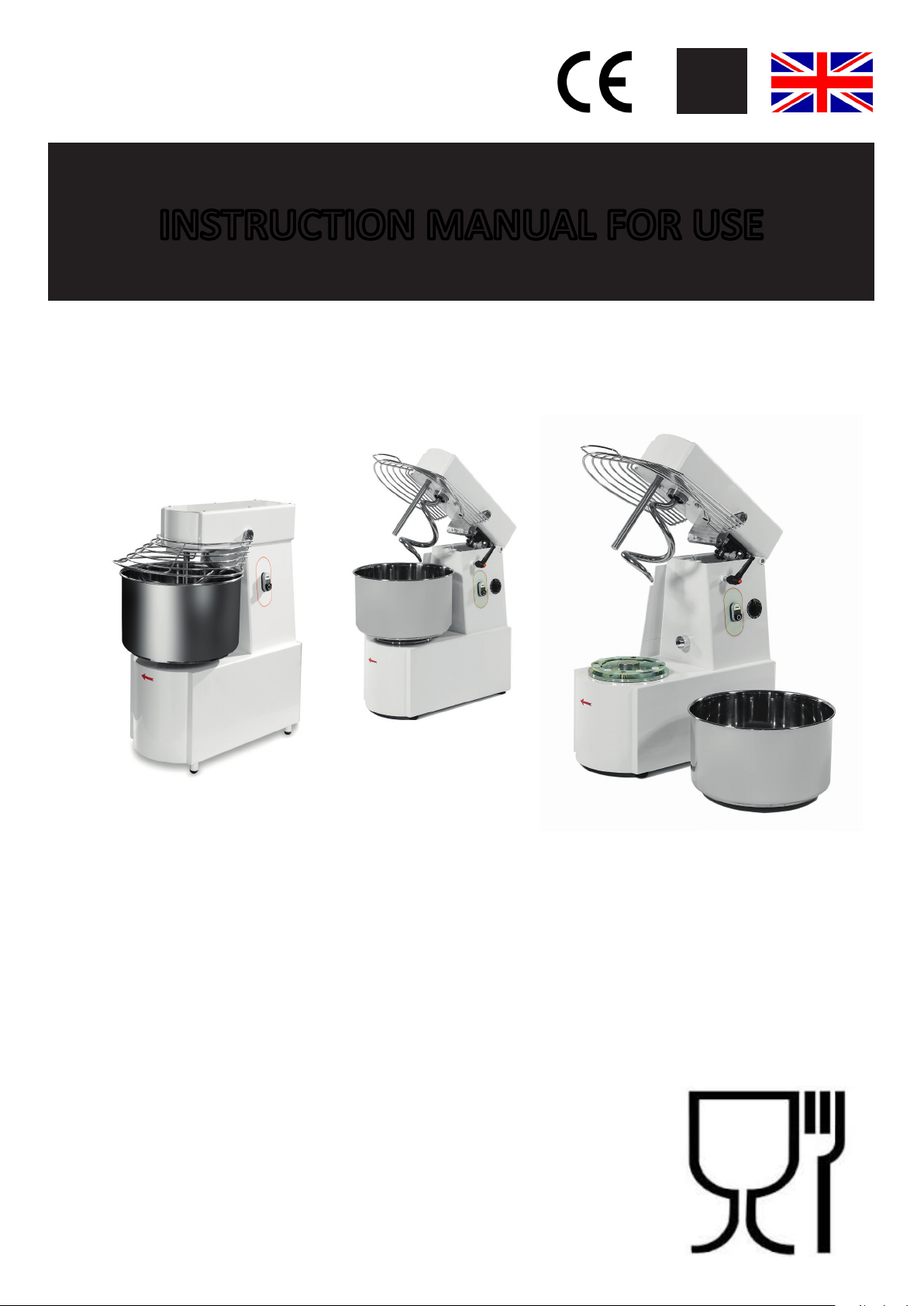

SPIRAL MIXER SK - RTF - RTS 0.0 3

INDEX

1.1. Purpose of the manual ............................................... 4

1.2. How to read the user manual ..................................... 4

1.3. Storing the manual ..................................................... 5

1.4. Updang the manual.................................................. 5

1.5. Recipients ................................................................... 5

1.6. Glossary and symbols ................................................. 5

2.1. Idencaon data of manufacturer ........................... 7

2.2. Idencaon data and machine data plate................ 7

2.3. Tests conducted before delivery................................. 7

2.4. Intended use and constricon parts........................... 7

2.5. Use condions ............................................................ 8

2.6. Set-Up responsabilies of the customer..................... 8

2.7. Technical data ............................................................. 8

2.8. Dimensioni macchina Serie SK.................................... 10

2.9. Dimensioni macchina Serie RTF.................................. 10

2.10. Dimensioni macchina Serie RTS.................................. 10

3.1. Transport and handling............................................... 11

3.2. Storage........................................................................ 11

3.3. Checks upon receipt ................................................... 11

3.4. Unpacking................................................................... 12

3.5. Liing the machine ..................................................... 12

3.6. Idenaon of the components................................. 13

3.7. Idencaon of the machine ..................................... 13

3.8. Assembling the wheels ............................................... 13

3.9. Mchine stability .......................................................... 14

3.10. Posioning the machine............................................. 14

3.11. Power supply .............................................................. 14

3.12. Checking the electrical connecon............................. 15

3.13. First start-up .............................................................. 15

4.1. Safety instrucon ....................................................... 16

4.2. Safety divices ............................................................. 16

4.3. Operator zones ........................................................... 16

4.4. Normal use, improper use, prohibited use................. 17

4.5. Warnings on residual risks ......................................... 17

4.6. Residual risks .............................................................. 17

5.1. Control panel .............................................................. 19

5.2. Commessioning .......................................................... 19

5.3. Stop............................................................................. 20

5.4. Switching o ............................................................... 20

5.5. Operaon safety ......................................................... 20

5.6. No voltage................................................................... 20

5.7. Opening the mobile guard.......................................... 20

5.8. Removing the tank ..................................................... 20

6.1. Requisites of the maintenance technican................... 21

6.2. Maintenance prescripon .......................................... 21

6.3. Roune maintenance intervaon ............................. 22

6.4. Scheduled maintenance intervenon ........................ 23

6.5. Ceck list -Roune Maintenance .................................. 24

6.6. Ceck list - Scheduled Maintenance ............................. 24

6.7. Troubleshoong.......................................................... 25

6.8. Cleaning ...................................................................... 26

7.1. Scarpping .................................................................... 27

7.2. Demolion .................................................................. 27

7.3. Disposal ...................................................................... 27

8.1. SK & RTF......................................................................... 28

8.2. RTS 1 Speed ................................................................... 29

8.3. RTS 2 Speeds.................................................................. 30

All component parts, equipment, excluding electrical parts, have a warranty of 12 months, provided that the defects

are due to the construcon. The shipment of the pieces in queson will be COD. Parts replaced under warranty will

be invoiced; upon receipt of the pieces (returned free port), which was requested replacement, we will provide with a

credit note. The warranty does not cover the replacement of the machine. The warranty does not cover labor charges

for replacement of parts and any other addional expenses.

The goods travel at the risk of the customer. Any complaints on the bad condion of the material should be shown to

the carrier at the me of Uploading. Please give due consideraon to what the subject of the liability of the carrier and

the mandatory nature of the highlight of any damage at the me of Uploading. We underline that our company is not

liable for damage not idened to the carrier at the me of collecon of the goods, even if the same was forwarded

free port debit invoice.

Any dispute is referred to the court with territorial jurisdicon of the oce of the manufacturer.