Retsch GmbH 2

Information on these operating instructions .................................. 4

Warnings..................................................................................... 4

Repairs........................................................................................ 4

Safety .................................................................................................. 5

Safety instructions ....................................................................... 5

Safety directives summarised, part 2 .......................................... 7

Confirmation ...................................................................................... 8

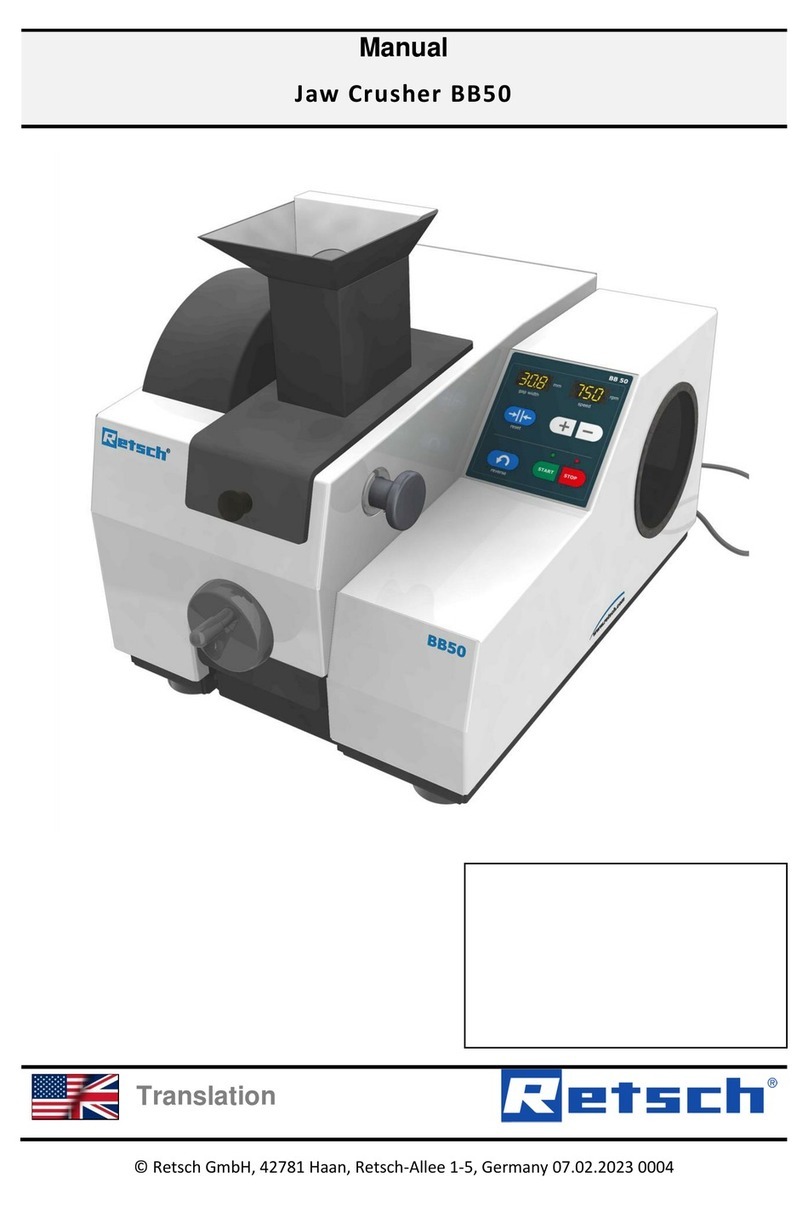

Technical specifications ................................................................... 9

Intended use ............................................................................... 9

Maximum feed volume ................................................................ 9

Maximum feed grain size ............................................................ 9

Drive output ................................................................................. 9

Emissions.................................................................................... 9

Materials and analyses of the grinding tools ............................... 9

Protection systems ...................................................................... 9

Protective equipment .................................................................. 10

Operating mode .......................................................................... 10

Device dimensions ...................................................................... 10

Base area required...................................................................... 10

Transport and assembly ................................................................... 11

Packaging ................................................................................... 11

Transport ..................................................................................... 11

Temperature fluctuations ............................................................ 11

Intermediate storage ................................................................... 11

Assembly..................................................................................... 11

Requirements for the assembly site ............................................ 12

Electrical connection ................................................................... 12

Serial interfaces .......................................................................... 13

Operation............................................................................................ 14

Connect the power ...................................................................... 14

Opening / closing / emergency unlocking of

the grinding chamber .................................................................. 14

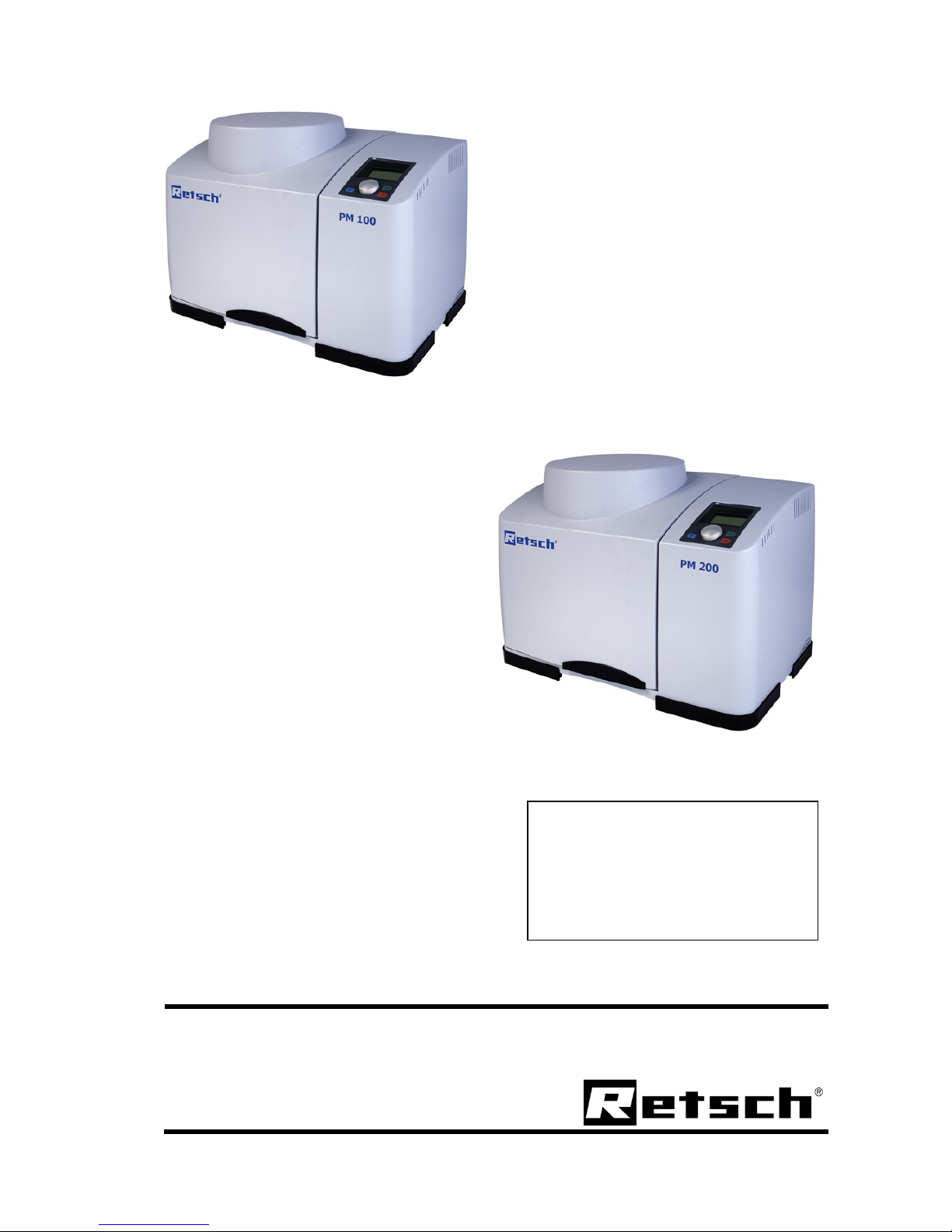

Inserting and clamping grinding bowls in the PM100 .................. 16

Removing the grinding bowl fastening device in the PM100 ....... 17

Tightening and unscrewing the grinding bowl fastening

device using a counter spanner .................................................. 17

Safety Instructions for starting the PM 100 ................................. 18

Balancing –only required for the PM100 .................................... 20

Balancing –only for PM 100 with additional balance weight....... 20

Inserting and clamping grinding bowls in the PM200 .................. 21

Tightening and loosening the grinding bowl clamping

fixture using the counter spanner ................................................ 21

Safety instructions for starting the PM 200.................................. 22

Suitable grinding bowls for the PM100 ........................................ 23

Grinding bowl filling level............................................................. 23

Guide values for material volumes and balls .............................. 23

Stacking of 50 ml milling cups of type “C” ................................... 23

Stacking of milling cups less than 50 ml ..................................... 23

Suitable grinding bowls for the PM200 ........................................ 24

Grinding bowl filling level............................................................. 24

Guide values for material volumes and balls .............................. 24

Stacking 50ml grinding bowls of type "C".................................... 24

Handling grinding bowls of type "C" ............................................ 24

Carrying and holding ................................................................... 24

Torsion lock ................................................................................. 24

Heating the grinding bowls .......................................................... 24

Grinding bowl identification ......................................................... 25

Customer marking of grinding bowls ........................................... 25

Cleaning the grinding bowls ........................................................ 25

Drying the grinding bowls ............................................................ 25

Tips for ultra-fine milling .............................................................. 25

Use of the closing device for milling cups ................................... 26

Operation via the PM100/200 display unit................................... 27

Symbols in the display unit.......................................................... 27

Menu structure of the display unit ............................................... 28

Adjustment options via the display menu .................................... 29

Languages .................................................................................. 29

Incorrect language selection ....................................................... 29

Manual mode............................................................................... 29

Grinding program 01 .................................................................. 29

Grinding time ............................................................................... 29