XI. The warranty protection does not cover the parts of the device subject

to the normal usage and the following cases:

a) mechanical damage of the product

b) defects and damages through:

- improper storage or transport

- improper or non-compliant use and maintenance (i. e. inconsistent

with the manual)

- using the device in the improper conditions (too high humidity, too high

or too low temperature, impact of the surrounding, sun etc.)

- unauthorized (i. e. by the user or other unauthorized persons) repairs,

modifications or construction changes

- connecting equipment inconsistent with the technical documentation

- connecting additional equipment, which is not recommended by the

supplier

- improper power supply

c) elements which wear and tear such as discolour of the housing

If there is any of the above, the claimant will be charged for transport and

/or repairs.

XII. During collection of the device, the item must be checked exactly

by the receiver to exclude transport damages. If any of them is observed,

the damage report in presence of the supplier have to be filled - such

report is the basement for transport complaint. The damage report must

be provide by the carrier.

XIII. The supplier does not take the responsibility for potential losses and

damages related to the downtime of the device during its failure and the

complaint considering.

XIV. Any changes in the Warranty Terms, improper use of the product

as well as traces of self repairing (beyond the Reventon's service)

or alterations cause, the warranty become invalid.

XV. These supplier’s Warranty Terms do not exclude or limit any rights

arising from the pledge.

XVI. Not following to any of the warranty regulations makes the

protection invalid.

XVII. All correspondence should be send to the following address:

Reventon Group Sp. z o.o. [Ltd.], 556 Wyzwolenia Street, 43 340 Kozy,

Poland or email address: serwis@reventongroup.eu.

7. WARRANTY TERMS

I. The supplier Reventon Group Sp. z o. o. [Ltd.] provides to the owner 24-

month warranty protection period for the following devices:

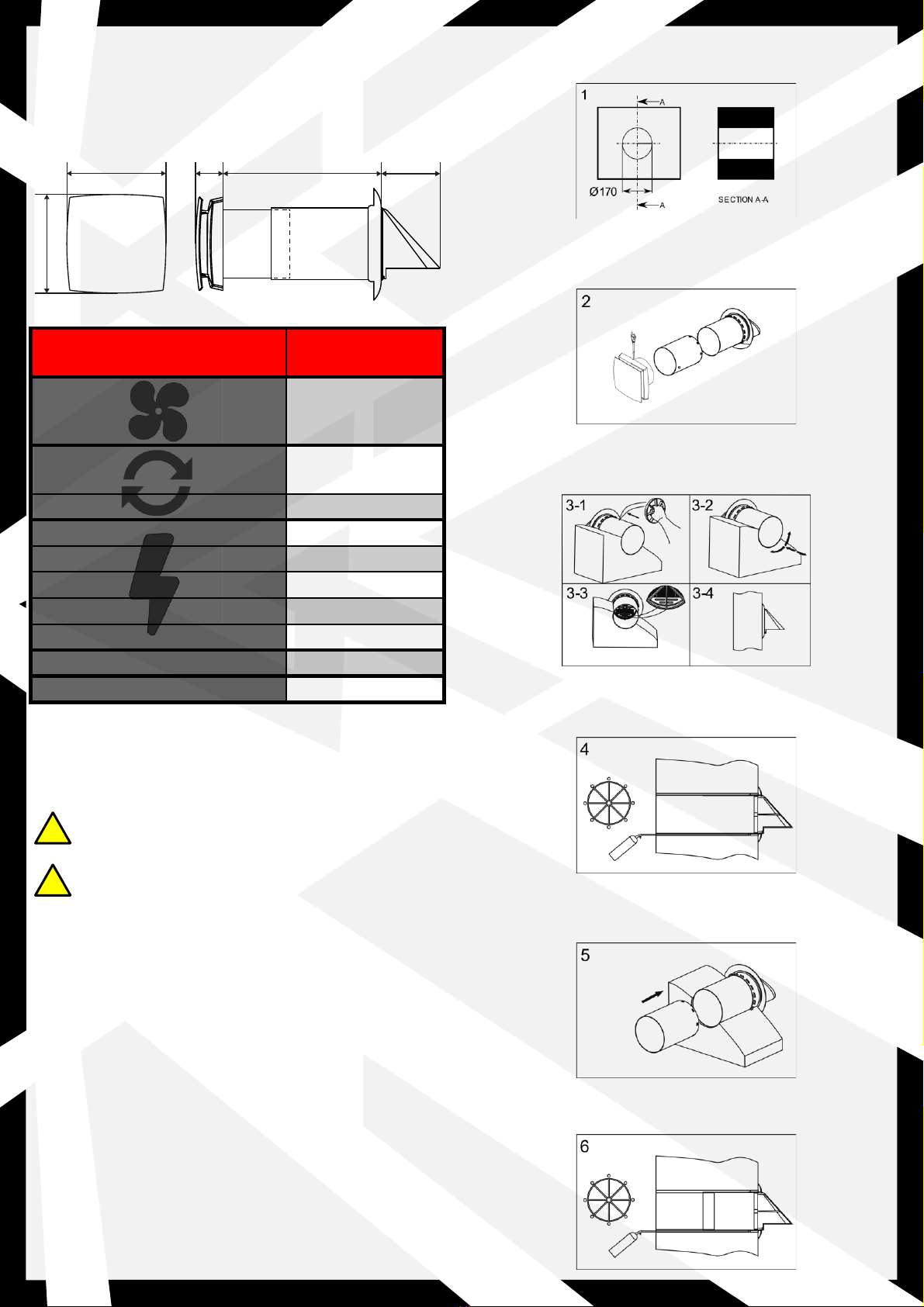

- wall energy recovery unit WALLER 64

II. The warranty protection is valid from the purchasing date (i.e. the issue

date of invoice) but not longer than 30 months from leaving the supplier's

warehouse.

III. The complaint should be sent by the complaint form on the website

(https://reventongroup.eu/en/complaints). The scan or the photo of the

fulfilled warranty card (the card is not required in case of accessories) and

the purchase invoice must be attached to the form. The Warranty Card

is not required in case of accessories.

IV. The supplier is committed to consider the claim within 14 working days

since the date of reporting (i. e. the day of receipt of the correctly fulfilled

warranty form).

V. In exceptional cases, the supplier reserves the right to extend the time

for consideration of the request, especially if the defect is not permanent

one and its determination requires a deeper analysis. The extension must

be notified by the supplier before the end of the 14th working day.

VI. Under the guarantee protection, the supplier provides a repairment,

replacement (the device or its component) or refund for the defective

item within a specified time.

VII.In the case of replacement of a device component, the warranty

protection of the whole unit is not prolonged.

VIII. The supplier does not cover the costs of disassembly and eventual

reassembly of the complaint device.

IX. The supplier may decide to bring the defective device or its component to the

Reventon's service. In such case the transport of the item is organised and paid

by the producer. The responsibility of the device's owner is to prepare the item

for the shipment - the device must be packed in a way which protects it against

transport damages and the dimensions and weight of the package must not

exceed 660 x 650 x400 mm and 30 kg respectively. In the case of elements

which cannot be packedin this way, the method of shipment must be agreed and

approved by Reventon Group Sp. z o. o. [Ltd.]. In the case of sending a non-

standard package without agreement of the supplier, the supplier reserves the

right to charge the owner of device with all additional transport costs.

X. In the case of arrival of the authorized service of the supplier or an installer

to fix the complaint item, the customer must ensure them seamless access to the

device and allrequired media like electricity, water, lighting etc. free of charge.

Warranty Card

1 - Model and serial number* or product code 2 –Address and place of assembly

3 –Date of connection to: 4 –Stamp and signature of installer:

Heating/cooling installation (if applicable)

Ventilation installation (if applicable)

Electrical installation (if applicable)

* serial number is required only for water heaters HC-3S, HC-EC and FARMER HCF series and recovery units INSPIRO, INSPIRO BASIC and VERTIC series