LETTER OF TRANSMITTAL

RECORD THE INCORPORATION OF THIS REVISION ON THE REVISION RECORD.

RETAIN THIS LETTER OF TRANSMITTAL, FILE IT BEHIND THE REVISION RECORD.

Revere Supply Co., Inc., Jacksonville, FL 32254

T. 904.786.0033 F. 904.786.0890

LT - 2

Pages Affected Pages: Added (A)

Replaced (RP)

Removed (RM) Revision Highlights

CHAPTER 7 7-1, 7-10

CHAPTER 8 8-1

8-5

8-6

8-7, 8-8

8-10

8-20

8-23, 8-24

8-26

8-33 THROUGH 8-40

8-41 THROUGH 8-48

8-49

8-50 THROUGH 8-52

CHAPTER 11 11-1

11-9, 11-10

11-12

11-13, 11-14, 11-15

11-16, 11-17

11-18, 11-19

11-20, 11-21

11-22

11-23

11-24

11-25

11-26

APPENDIX A

RP

RP

RP

RP

RP

RP

RP

RP

RP

RP

A

A

A

RP

RP

RP

RP

RP

RP

RP

RP

RP

RP

RP

RP

A

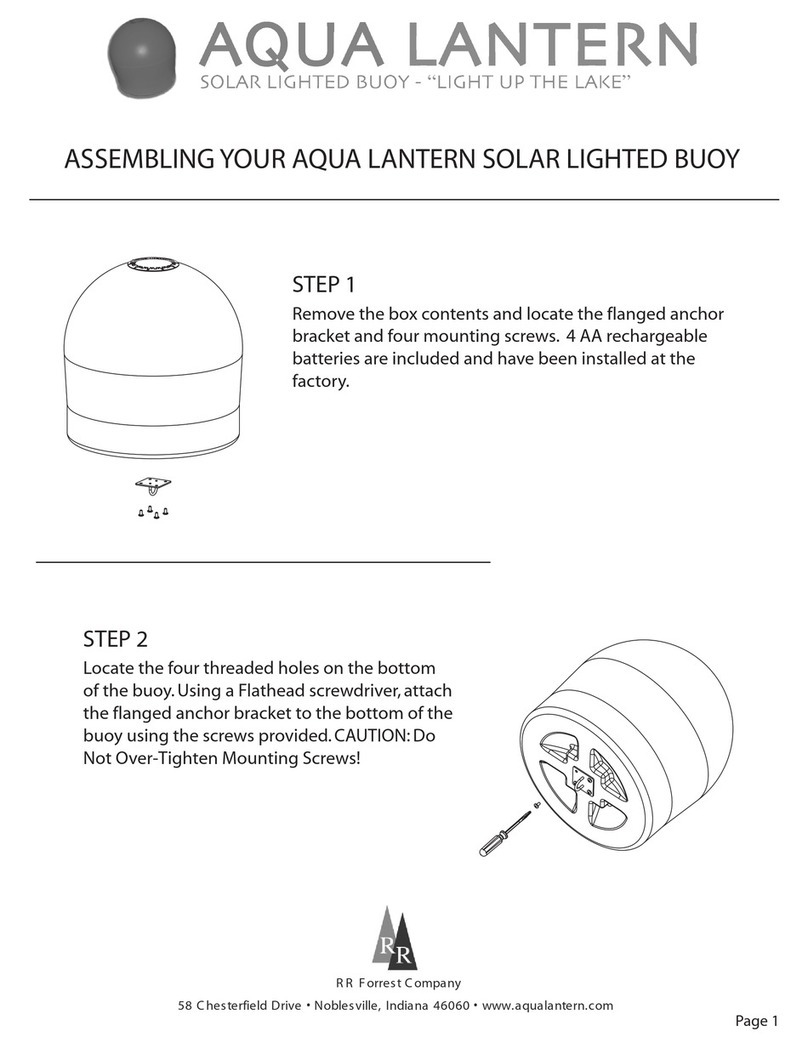

Added canopy to component repair

Added canopy to component setup

Clarified length of cord used for light attachment

Added canopy folding instructions

Adjusted figure positions

Added torque setting to Table A

Added CC6 to Table B

Updated procedure with canopy instructions, Added

Table D

Added canopy kit illustration

Revised CC4 folding illustations to include canopy kit

Added CC6 folding illustrations

Figure 9 revised to show canopy kit storage

Adjusted figure positions

Changed page number of Image List

Updated list to include new part numbers

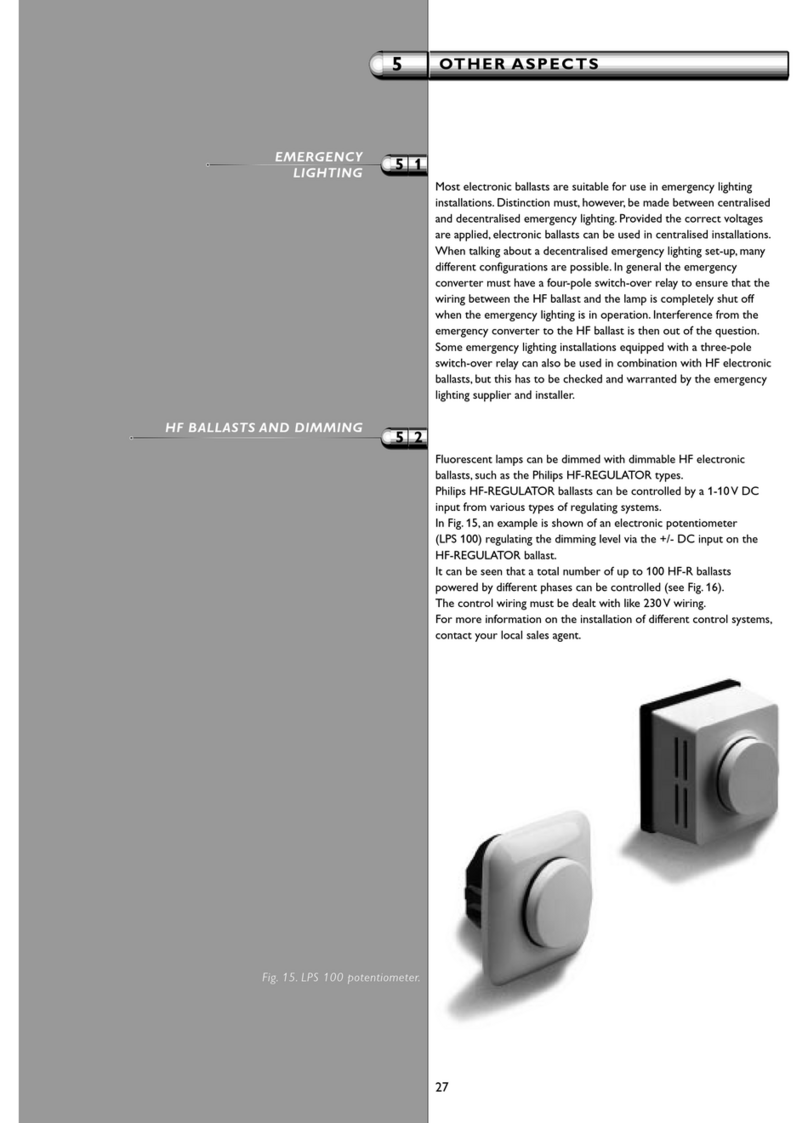

Updated Fig. 1 to show canopy

Updated item list to include canopy components and CC6

Adjusted Fig. 2 position. Updated item list to include CC6

components

Adjusted Fig. 3 position. Update item list to include CC6

components

Adjusted Fig. 4 and item list position

Added Fig. 5

Adjusted page number Image List begins.

Changed knife image, removed knife sheath

Added key ring image

Added canopy buckle strap

Added Appendix A