815 Nm (600 ft lbs)

80 Nm (60 ft lbs)

(#8) Optional

Weld Location

(TAB)

ALIGNMENT

M-6

ALIGNMENT

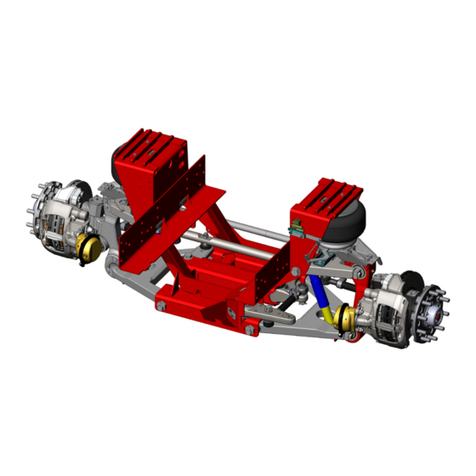

1. Release the brake system and pull the

trailer forwards and backwards several

times in a straight line to free the suspen-

sion from binding and tension.

NOTE: This procedure must be performed

on a smooth level surface.

2. For best results, the use of axle extensions

and a “BAZOOKA” type king pin post, or

a suitable optical alignment device are

recommended.

3. NOTE: Prior to commencing alignment,

ensure that the trailing beam is installed to

centre line of hanger. Align the front axle

with the king pin as shown.

4. Align the remaining axles to the front axle as

shown.

5. Torque the hanger clamp bolts if

REY-ALIGNTM or if huck bolted, weld the

alignment washers as shown.

6. (REY-ALIGNTM feature) torque 22 mm (7/8”)

alignment clamp bolt to 815 Nm (600 ft lbs)

using only a torque wrench.

NOTE: 1) Refer to page M-14 for details.

2) Run nut up very slowly.

7. Torque the adjustment shaft (REY-ALIGNTM

feature) clockwise to 80 Nm (60 ft lbs) or, if

Huck®Bolt, weld the alignment washers as

shown on the right.

8. (If replacing Huck Bolted) torque 28 mm

(1-1/8”) replacement pivot bolt to 1110Nm

(820 ft lbs). Run nut up very slowly.

9. Optional: Weld along top of “TAB” to secure

alignment in position.

NOTE: By removing welds carefully, you

should be able to re-align up to 3 or 4

times with minimal or no cleaning.

10. Verify that torque is correct on all fasteners.

11. After initial 1,600 kms (1,000 miles), the

alignment should be re-checked and

corrected if necessary, torque on the clamp

nuts should also be checked.

Alignment Procedure

A=B +/- 1/8” (3.2)

C=D +/- 1/16” (1.6)

Bushing - Ref.

1/4”

(6.4)

Weld all around alignment washers

STANDARD HUCK®BOLT ASSEMBLY

OPTIONAL REY-ALIGNTM SYSTEM

NOTE: Figures in brackets are shown

in millimeters.