INTRODUCTION

- 4 - D9790

REV G

08 /28 /202 3

Company Profile

Reyco Granning Suspensions was formed by the merger and acquisition of two well -known

names in the heavy duty veh icle suspension industry —Reyco and Granning.

Reyco grew out of the Reynolds Mfg. Co and was rst known as a major supplier of brake

drums for heavy duty vehicles and later developed a full lin e of air and steel -spring

suspensions for trucks, buses, trail ers and motorhomes.

Granning Air Suspensions was founded in 1949 in Detroit, Michigan as a manufacturer of

auxiliary lift axle suspensions. Granning later became an innovator of independent fr ont air

suspensions for the motorhome industry.

Reyco Grannin g manufacturing facilities are certied to the ISO 9001:2015 standards, a

globally -recognized assurance that quality standards have been established and are

maintained by regular rigorous audit s.

Reyco Granning LLC was formed in early 2011 through a part nering of senior managers and

MAT Capital, a private investment group headquartered in Long Grove, Illinois.

Congratulations on your purchase of a ReycoGranning ®drive axle air suspension syste m.

Founded in 1948 by one of the pioneers of air suspensions, ReycoGranning ®Air Suspensions

supplies drive and tag axle air suspension systems to a variety of original equipment

manufacturers as well as to the aftermarket industry. The R -Series are utili zed by OEM

customers in applications such as recreational vehi cles, shuttle bus, trailer, chassis builders,

Type I and III ambulances and class 3 through 8 truck applications. This product line now

exceeds 25 models that cover all major chassis utilized i n the above applications.

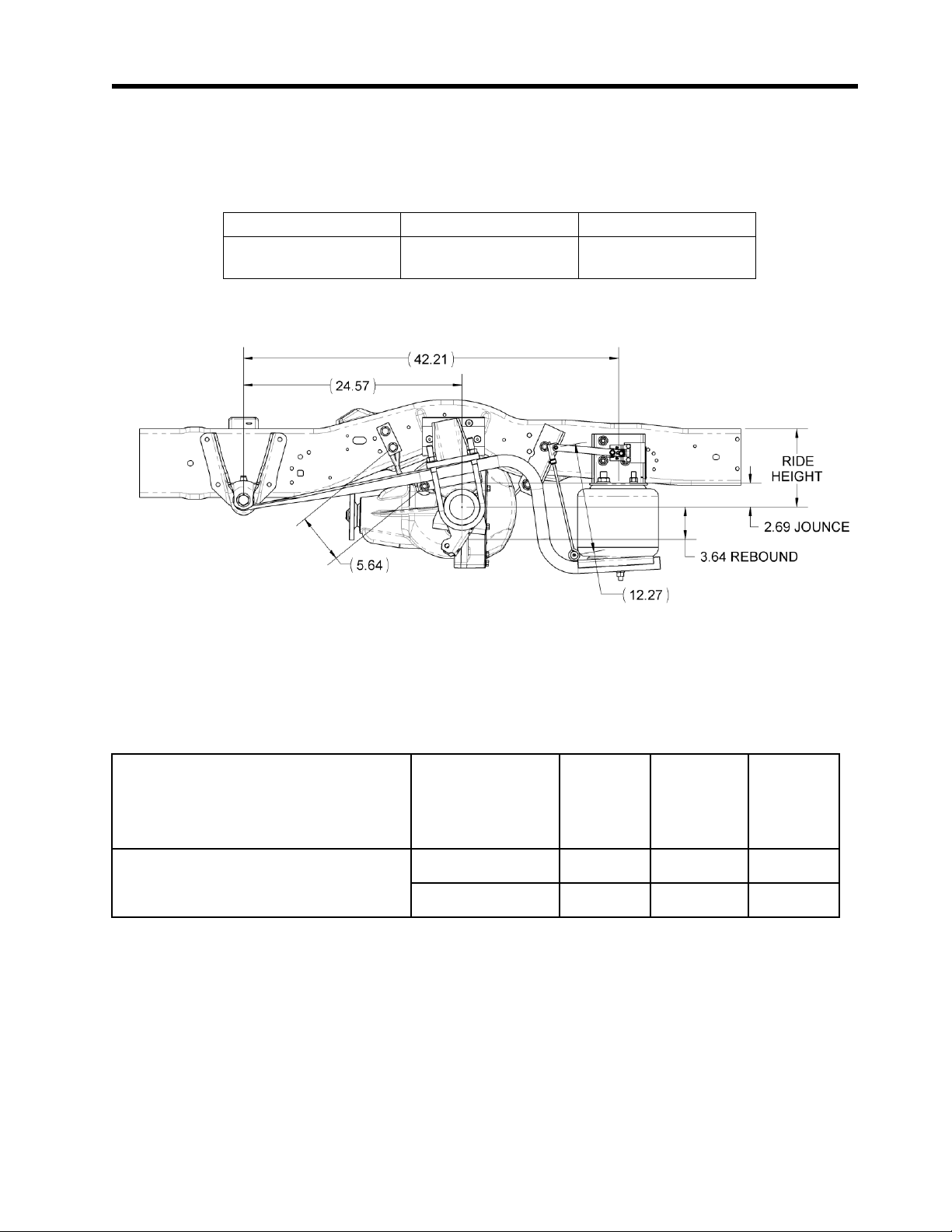

Suspension Description

A ReycoGrann ing®drive axle air suspension system is a replacement rear suspensions system

that consists of an air control system, air springs, trailing arm beams, brackets, and mounting

hardware. In gener al, the air suspension works by maintaining a constant ride he ight by

adjusting the amount air pressure in the air springs. This allows the vehicle to remain level,

regardless of loading. By varying the amount of air pressure in the springs, a comfortabl e ride

is maintained whether lightly or heavily loaded. This is the major dierence between an air

suspension and a conventional steel spring suspension. The steel spring suspension is usually

designed for heavily loaded condition and thus yields a hars h ride in lightly loaded conditions.

In addition, the steel s pring suspension does not maintain a constant ride height under varying

load conditions.

By maintaining a constant ride height, the horizontal center of gravity, steering geometry, and

even the headlights remain level. The benets of an air ride are: