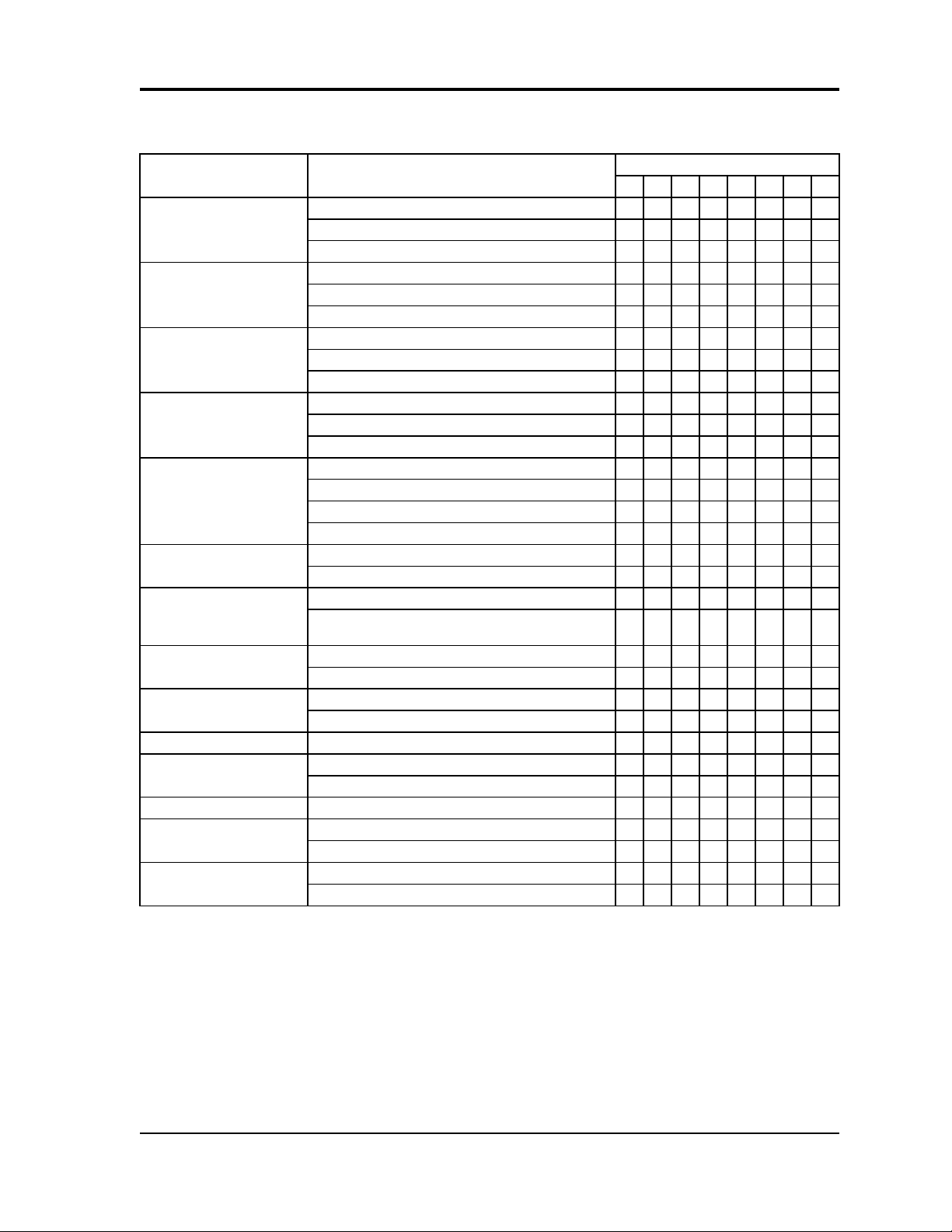

Table of Contents

D711987 2 IFS1700S

Seal Inspection ................................................................................................................ 31

Endplay Inspection.......................................................................................................... 31

Inspecting Wheel Bearing Endplay.................................................................31

Inspecting the Knuckle Carrier Bearing and Seal ...........................................32

Inspecting the Kingpin Vertical Endplay........................................................32

Adjustments ...............................................................33

Adjusting Wheel End Play ..............................................................................33

Adjusting Suspension Ride Height .................................................................35

Adjusting the Maximum Wheel Turn Angle ..................................................36

Inspection before Alignment...........................................................................37

Wheels and Tires............................................................................................................. 37

Front Suspension............................................................................................................. 37

Rear Axle and Suspension .............................................................................................. 38

Front Wheel Alignment...................................................................................38

Equipment....................................................................................................................... 38

General............................................................................................................................ 38

Preparation ...................................................................................................................... 39

Adjusting the Camber Angle...........................................................................40

Eccentric Camber Adjustment ........................................................................................ 40

Bar Pin Camber Adjustment ........................................................................................... 42

Adjusting the Caster Angle .............................................................................42

Eccentric Caster Adjustment........................................................................................... 43

Adjusting the Toe-In .......................................................................................44

Repair .........................................................................46

General Procedures..........................................................................................46

Cleaning the Parts............................................................................................46

Ground or Polished Parts ................................................................................................ 46

Rough Parts..................................................................................................................... 47

Drying ............................................................................................................................. 47

Preventing Corrosion ...................................................................................................... 47

Replacing Tie Rod Ends..................................................................................47

Removal .......................................................................................................................... 47

Installation....................................................................................................................... 47

Replacing the Relay Rod Ball Joints...............................................................48

Removal .......................................................................................................................... 48

Installation....................................................................................................................... 48

Replacing the Bell Crank, Idler Arm, and Crank Arm Bearings ....................48

Removal .......................................................................................................................... 49

Installation....................................................................................................................... 49

Replacing the Upper and Lower Control Arm Bushings ................................49

Upper Control Arm Removal.......................................................................................... 50

Upper Control Arm Installation ...................................................................................... 50