Page 2of 36

D714425 REV A 9/18

TABLE OF CONTENTS

Int roduction ………………………………………………………………………………………………………………………………….. 3

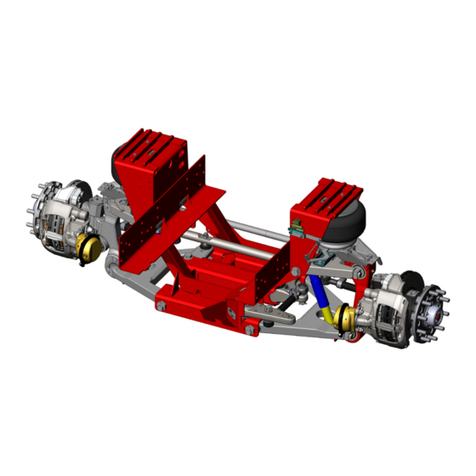

Product Overview ………………………………………………………………………………………………………………………….. 5

Safety Instructions …………………………………………………………………………………………………………………………6

Preparation ……………………………………………………………………………………………………………………………………7

Tools, parts, consumables and documents required ……………………………………………………………………. 7

Quick checklist ………………………………………………………………………………………………………………………………7

Installation ……………………………………………………………………………………………………………………………………8

Kit List …………………………………………………………………………………………………………………………………………... 8

Step 1 – Support the vehicle ……………………………………………………………………………………………………….. 10

Step 3 – Connect air compressor DC common and plug in main harness ……………………………………11

Step 4a – Mount the driver and passenger ride height sensors ………………………………………………….. 12

Step 4b – Harness connections to the ride height sensors ………………………………………………………….. 14

Step 5a – Feed the harness into the cab ………………………………………………………………………………………15

Step 5b – Mount the rocker switch ……………………………………………………………...................................... 15

Step 5c – Extend rocker switch wires (if required) ………………………………………………………………………. 16

Step 5d – Connect ignition and D C common control wires …………………………………………………………. 17

Step 5e – Connect to the vehicle CAN bus network …………………………………………………………………….. 18

Step 6 – Connect door switch input …………………………………………………………………………………………….. 19

Step 7 – Connect motion warning output ……………………………………………………………………………………. 20

Step 8 – Connect low pressure output …………………………………………………………………………………………21

Step 9a – Air -line push -in ttings …………………………………………………………………………………………………22

Assembly instructions ……………………………………………………………………………………………………22

Removal instructions ……………………………………………………………………………………………………. 22

Step 9b – Connect air -line between the air dryer & main air tank with a check valve ……............... 23

Step 9c – Connect air -lines for the driver & passenger air springs …………………………........ ............... 24

Step 9d – Connect air supply & exhaust air -lines ……………………………………………………………………….. . 25

Step 10a – Connect persistent 1 2VDC supply to 50 Amp auto reset breaker and main harnes s …26

Step 10b – Connect persistent 12VDC supply to 10 Amp in -line breaker ……………………………………. 26

System Setup ……………………………………………………………………………………………………………………………… 27

Introduction ………………………………………………………………………………………………………………………………. 27

Step 1 – Move the vehicle to a drive -on service pit or hoist …………………………………........................ . 27

Step 2a – Select Ride Height Sensor Setup Mode ………………………………………………………………………. 28

Step 2b – Adjust height sensor levers ……………………………………………………………………………………….. 29

Step 2c – Optionally exit Setup Mode ……………………………………………………………………………………….. 30

Step 2d – Perform Travel Zero -Set ……………………………………………………………………………………………. 30

Step 2e – Optionally exit Setup Mode ………………………………………………………………………………………. 30

Step 2f – Enter Kneel Height Setup Mode …………………………………………………………………………………30

Step 3 – Finishing the installation …………………………………………………………………………………………….. 31

Support Contact Information ……………………………………………………………………………………………………. 32

Installation Validation Checklist ………………………………………………………………………………………………. 33

REV ECR # DATE CHANGE DESCRIPTION BY CHK APV

OR 21039 6/8/17 RELEASED FOR PRODUCTION JCR - -

A 21341 6/15/18

Improvements to information LLG MGO JAH