3

Pre-Use & Setup

The Rhyas TURBO MIG 135 welder enables the end-user to configure the machine to be used

either as a GAS MIG welder or a NO GAS MIG welder.

Modifying or incorrectly setting up of the welder could cause permanent damage and invalidate

the warranty. Please see configuration details below.

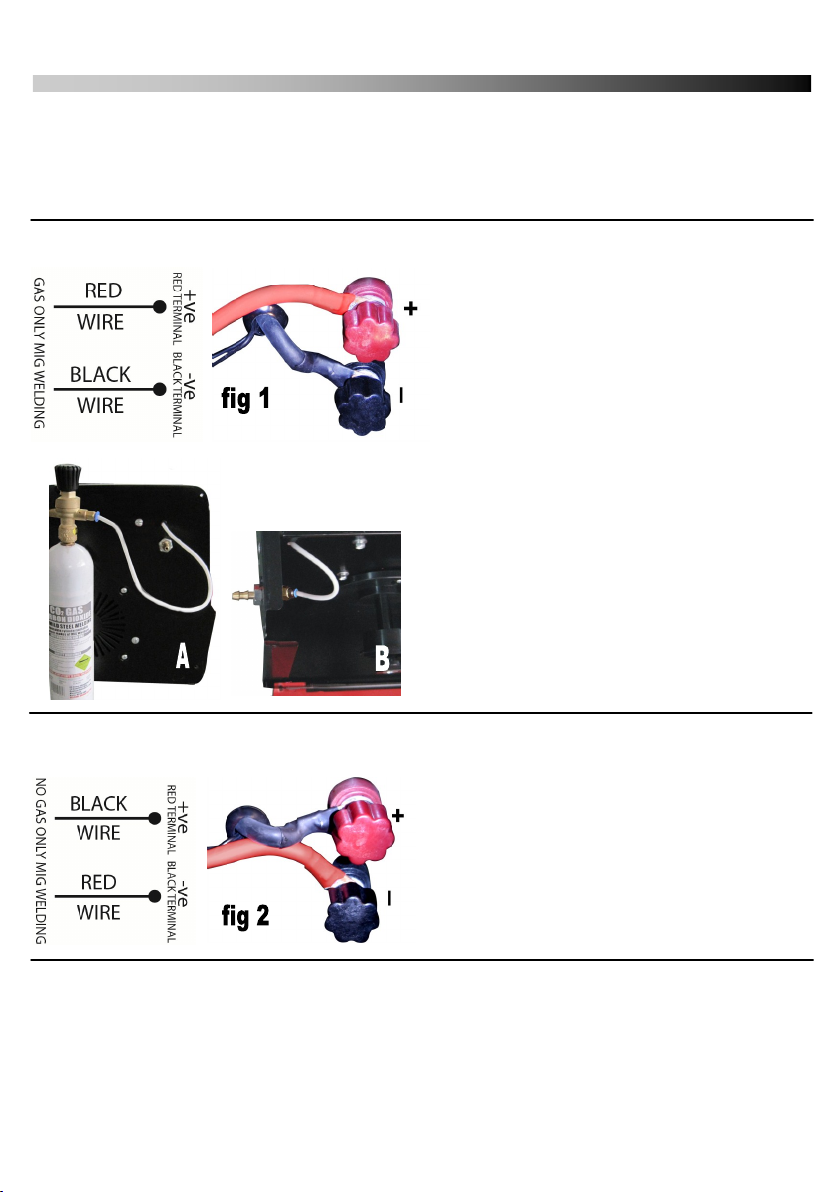

GAS MIG WELDING CONFIGURATION

The 0.6mm to 0.8mm wire feed roller must

be installed.

Solid welding wire ONLY in the range of

0.6mm to 0.8mm to be used.

The correct torch tip to be used

corresponding to the wire thickness selected.

Gas can be connected by one of two

methods:-

A. The gas feed tube can be passed through the rear of the welder and

push fit connected to the gas regulator for use with the sample small gas

bottle supplied.

B. To use larger gas bottles with your own main

hose and appropriate regulator the gas tube can

be push fitted onto the hose tail as shown. Ensure

gas bottle being used is securely retained in an

upright position.

NO GAS MIG WELDING CONFIGURATION

To use the welder as a NO GAS MIG welder:-

The internal electrical power leads must be

attached as per (fig 2)

0.9mm fluxed wire to be used only.

The 0.9mm wire feed roller must be inserted.

The 0.9mm torch tip must be applied

No GAS required, GAS regulator can be

closed.

IMPORTANT: The configurations above must be followed, failure to do so can cause

permanent damage to the welder and invalidate any warranty.

Welding and the use of welding equipment requires care and attention to detail, protection from

heat, fumes and welding glare. Please seek professional advice and training to ensure the safe

and correct use of the welder. Save these pre-use and setup details for future reference.