Rice Lake SCT-3300 User manual

Other Rice Lake Transmitter manuals

Rice Lake

Rice Lake 30 Series Administrator Guide

Rice Lake

Rice Lake SCT-1100 User manual

Rice Lake

Rice Lake SCT-1SX-PROFINET User manual

Rice Lake

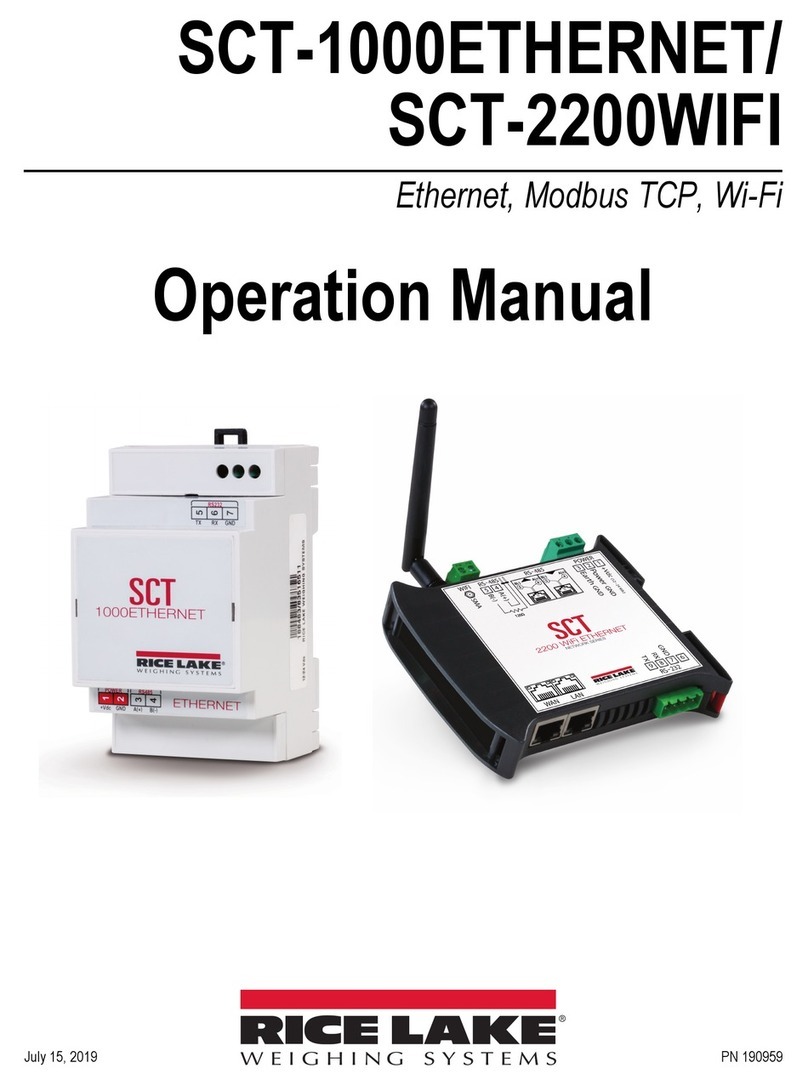

Rice Lake SCT-1000ETHERNET User manual

Rice Lake

Rice Lake SCT-1SX-MODBUS TCP/IP User manual

Rice Lake

Rice Lake 20 series User manual

Rice Lake

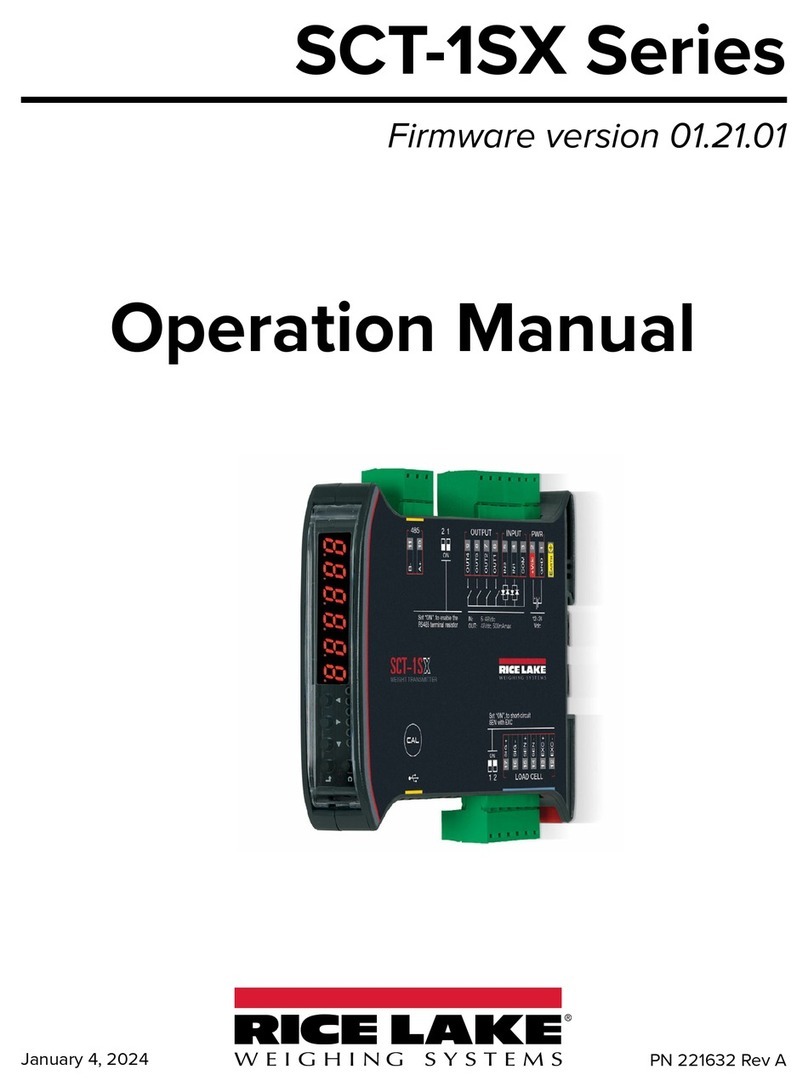

Rice Lake SCT-1SX Series User manual

Rice Lake

Rice Lake SCT-2200 User manual

Rice Lake

Rice Lake Advanced Series User manual

Rice Lake

Rice Lake SCT-1SX Series User manual

Rice Lake

Rice Lake SCT-1SX Series User manual

Rice Lake

Rice Lake SCT-2200 User manual

Rice Lake

Rice Lake MSI TranSend Series User manual

Rice Lake

Rice Lake SCT-1SX-AN User manual

Rice Lake

Rice Lake SCT20-DN User manual

Rice Lake

Rice Lake SCT-1SX-Ethernet/IP User manual

Rice Lake

Rice Lake SCT-4X-MODBUS TCP/IP User manual

Rice Lake

Rice Lake SCT-2200 User manual

Rice Lake

Rice Lake SCT-4X Series User manual

Rice Lake

Rice Lake SCT-4X-AN User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide