Installation and Operating Manual

Series NKL, NKLP, NKS, NKSP, NK, NKP

9520-070-en

Revision 00

TM 5028 MPE/Wm

Page 3

Edition 01/2002

1 General

Manufacturer:

ITT Richter Chemie-Technik GmbH

Otto-Schott-Str. 2

D-47906 Kempen

Telephone : +49 (0) 2152 146-0

Fax: +49 (0) 2152 146-190

Internet: www.itt-richter.de

Designation:

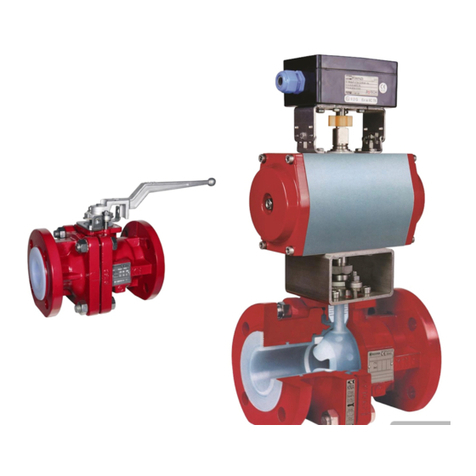

Shut-off and control butterfly valve in 3 body designs:

lug-style, sandwich-type and double flange.

Disc/stem unit plastic-lined, stainless steel or

Hastelloy

Leak-proofness tested to DIN 3230, Part 1

Gas-tight in the seat to DIN 3230, Part 3 leak rate 1

Flange connecting dimensions: DIN EN 1092-2,

shape B

(ISO 7005-2 type B) PN 16

Face to face: DIN EN 558-1, basic series 20 (ISO

5752 series 20)

General conditions of delivery to DIN 3230.

Weight:

See Section 9.4

Dimensions:

See Section 10

Materials:

Body material: Ductile cast iron EN-JS 1049 to DIN

EN 1563 (0.7043 DIN 1693)

Lining material: PTFE/PFA

on request conductive lining

Disc/stem unit: PFA-lined or ..-F

Stainless steel 1.4408 or ..-S

Hastelloy C4 ..-H

Temperature range:

-60 °C to +200 °C

(-

80 °F to +400 °F)

accord. to operating pressure

Operating pressure:

from vacuum to 10 bar

(145 psig)

accord. to operating pressure

Valve sizes in mm :

with hand lever: DN 50, 80, 100, 150, 200

2“, 3“, 4“, 6“, 8“

with worm gear DN 50, 80, 100, 150, 200, 250,

300, 350, 400

2“, 3“, 4“, 6“, 8“, 10“, 12“, 14“, 16“

NK only up to DN 300

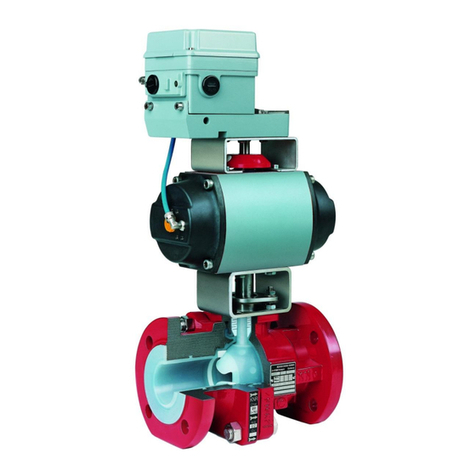

with actuator: DN 50, 80, 100, 150, 200, 250,

300, 350, 400

2“, 3“, 4“, 6“, 8“, 10“, 12“, 14“, 16“

NKP only up to DN 300

Activation:

Hand lever, lockable

Worm gear with handwheel

Pneumatic or electric

(connection to ISO 5211)

Options:

Safety stuffing box

Monitoring connection connection

Proximity initiator

Polished disc surfaces

1.1 Application

Richter shut-off and control butterfly valves are

pressure-maintaining components in accordance

with the German Pressure Equipment Directive

(DGRL) for the passage and shut-off of fluids. The

valves are suitable for vapours, gases and liquids of

group 1 according to the DGRL and have a

corrosion-resistant plastic lining.

The field of application for the shut-off and control

butterfly valves include:

Light and medium corrosive, pure and slightly

solids-laden liquids, vaopours and gases

Materials in contact with the medium which are

FDA-compliant can be used for food and phar-

maceutical feedstock as well as in biochemistry.

Powdered and granulated non or low abrasive

solids

Shut-off and control butterfly valves with a plastic-

lined disc/stem unit are used for highly aggressive,

corrosive media.

Shut-off and control butterfly valves with a stainless

steel disc/stem unit are suitable for less agressive

media, are cheaper and benficial for thorough valve

cleaning.

With all 3 body versions the valves can be installed

as a sandwich-type valve (intermediate flange valve),

with lug-style and double-flange body as a flange or

dead-end valve.

Product features:

Wide sealing surfaces of the body lining

Long valve neck for optimum heat insulation

Maintenance-free, self-adjusting stem seal

Leak-proof to the atmosphere in accordance with

the German Clean Air Code