9520-022-en Revision 16

TM 10477 Edition 05/2022

List of Contents

List of Contents .................................................... 2

Relevant documents............................................. 2

1Technical data ................................................ 3

1.1 Overview of sizes ............................................4

1.2 Type codes .........................................................4

1.3 Name plate, CE and body markings ...................5

1.4 Tightening torques ............................................. 6

1.5 Dimensions - Installation....................................8

1.6 Flow rate value kv [m³/h]..................................8

1.6.1 Disc/stem unit PFA-lined.........................................8

1.6.2 Disc/stem unit stainless steel, Hastelloy, Titan........9

1.7 Weights (ca. kg).................................................9

1.8 Breakaway torques ..........................................10

1.9 Cavitation coefficient z for 75% duty ...............10

1.10 Pressure-temperature-diagram .......................10

2Notes on safety............................................. 11

2.1 Intended use ....................................................11

2.2 For the customer / operator ............................ 11

2.3 Improper operation.......................................... 11

3Safety notes for applications in potentially

explosive areas based on the Directive

2014/34/EU (ATEX)....................................... 12

3.1 Intended use ....................................................12

4Safety note for valves, certified to Clean Air Act

(TA-Luft)....................................................... 14

5Transport, storage and disposal .................... 14

5.1 Storage .............................................................14

5.2 Transport preparations ....................................14

5.3 Return consignments .......................................14

5.4 Transport securing device................................14

5.5 Disposal ............................................................ 15

6Installation ................................................... 15

6.1 Installation possibilities.................................... 15

6.2 Flange caps and gaskets................................... 15

6.3 Direction of flow and installation position......15

6.4 Installation........................................................ 15

6.4.1 Additional advice for shut-off and control butterfly

valve with actuator................................................15

6.5 Earthing............................................................15

7Operation..................................................... 16

7.1 Initial commissioning........................................16

7.2 Improper operation and their consequences ..16

7.3 Shutdown .........................................................16

7.3.1 Additional advice for shut-off and control butterfly

valve with actuator................................................16

8Malfunctions ................................................ 17

9Maintenance ................................................ 17

9.1 Notes for assembly...........................................17

9.2 Valve actuation.................................................18

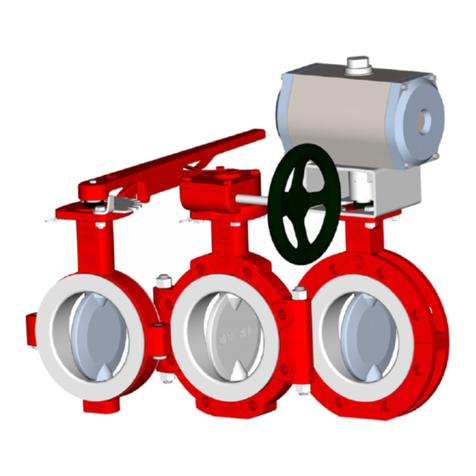

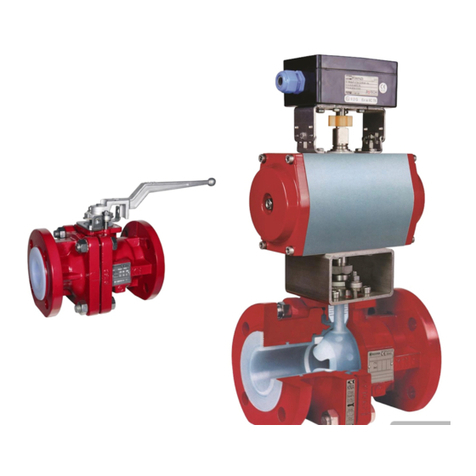

9.2.1 Actuated with lever...............................................18

9.2.2 Actuated by means of worm gear .........................18

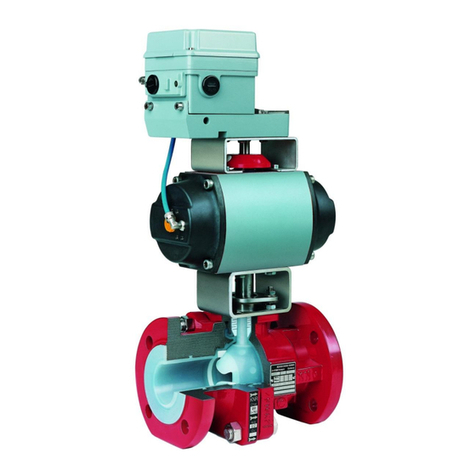

9.2.3 Remotely actuated................................................18

9.2.4 Required breakaway torque..................................18

9.3 Tests .................................................................18

10 Drawings ...................................................... 19

10.1 Legend..............................................................19

10.2 Sectional drawing NKS-C .................................19

10.3 Sectional drawing NKL-C ..................................20

10.4 Worm gear .......................................................20

10.5 Actuator............................................................21

10.6 Connection actuator.........................................21

10.7 Dimensional drawing NKS-C with hand lever .22

10.8 Dimensional drawing NKS-C with worm gear ..23

10.9 Dimensional drawing NKSP-C...........................24

10.10 Dimensional drawing NKL-C with hand lever26

10.11 Dimensional drawing NKL-C with worm gear..

......................................................................27

10.12 Dimensional drawing NKLP-C ......................28

Relevant documents

EG-Declaration of conformity

Manufacturer Declaration ATEX Directive

2014/34/EU

Certification of leakage rate

Form for Safety Information Concerning the Con-

tamination QM 0912-16-2001_en

For NKLP-C or NKSP-C, operating manual for actu-

ator