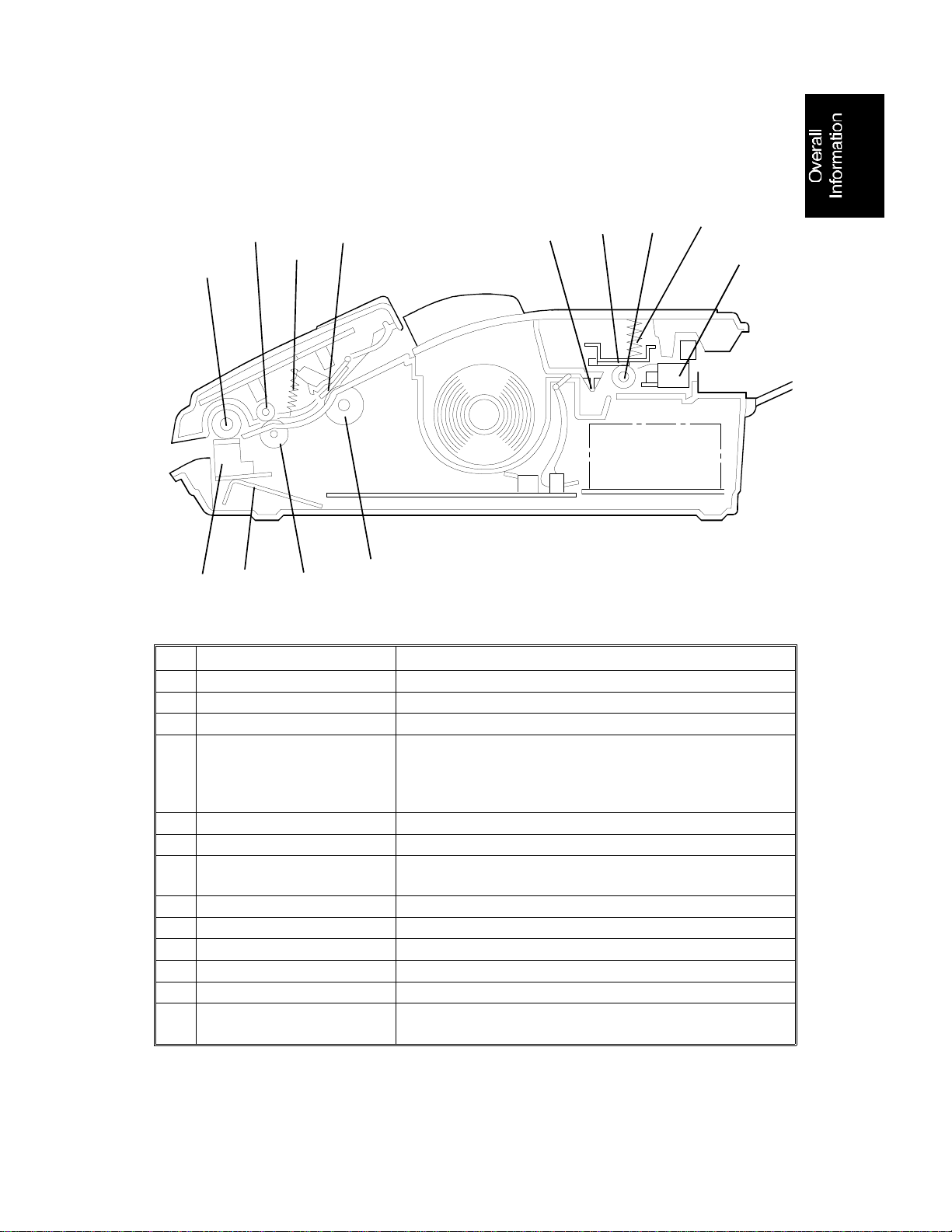

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS

Type

Desktop type transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length:

105 - 357 mm [4.1 - 14.1 ins]

Up to 0.6 m [23.6 ins], manually assisted

Up to 14.0 m [46 ft], after adjustment

Width:

148 - 257 mm [5.8 - 10.1 ins]

Thickness:

0.05 to 0.15 mm [2 to 6 mils]

(equivalent 50 - 80 g/m2)

Document Feed

Automatic feed, face down

ADF Capacity

10 sheets (using 20 lb or 80 g/m2paper)

Scanning Method

Contact image sensor

Maximum Scan Width

A4 : 210 mm [8.3 ins] ± 0.5% B4

( CHINA ) : 256 mm [10.1 ins] ± 0.5%

Letter : 216 mm [8.5 ins] ± 0.5%

Scan Resolutions

Main scan: 8 dots/mm [203 dpi]

Sub scan:

Standard - 3.85 lines/mm [98 lpi]

Detail - 7.7 lines/mm [196 lpi]

Fine - 15.4 lines/mm [392 lpi]

Memory Capacity ( BRO only )

ECM: 64 kbytes

SAF:

BRO:(ECM on) 148 kbytes

(12 pages/Slerexe letter)

(ECM off) 204 kbytes

(16 pages/Slerexe letter)

China BRO:(TAM on) 256 kbytes

(21 pages/Slerexe letter)

(TAM off) 916 kbytes

(75 pages/Slerexe letter)

Compression

BR0: MH, MR, MMR, EFC, SSC

BR1: MH, MR, EFC, SSC

Protocol

Group 3

Modulation

V.29 (QAM), V.27ter (PHM), V.21 (FM)

Data Rate (bps)

9600/7200/4800/2400,

Automatic fallback

I/O Rate

With ECM: 0 ms/line

Without ECM: 10, 20, 40 ms/line

Transmission Time

BRO: 9 s at 9600 bps

BR1: 20 s at 9600 bps

Measured with G3 ECM using memory for a

ITU-T #1 test document (Slerexe letter) at

standard resolution

Printing System

Thermal Printing

Printer Roll; Thermal paper

North American version:

216 mm X 30 m [8.5 ins X 98.4 ft]

China version:

256 mm X 30 m [10.1 ins X 98.4 ft]

Other versions:

210 mm X 30 m [8.3 ins X 98.4 ft]

Maximum Printing Width

North American version: 210 mm [8.3 ins]

China version: 250 mm [9.8 ins]

Other versions: 204 mm [8.0 ins]

Print Resolutions

Main scan: 8 dots/mm [203 dpi]

Sub scan: 15.4 lines/mm [392 lpi]

Power Supply

USA : 115 ±20 Vac, 60 ±3 Hz

China : 220 ±20 Vac, 50 ±3 Hz

Asia : 220 - 240 V, 50/ 60 ±3 Hz

Operation Enviroment

Temperature: 17 ~ 28 °C [63 ~ 82 F]

Humidity : 40 ~ 70 %Rh

August 7th, 1995 OVERALL MACHINE INFORMATION

SPECIFICATIONS

1-1