Ricoh Shepherd-Lt Service manual

Other Ricoh Printer Accessories manuals

Ricoh

Ricoh Aficio AP4510 Reference guide

Ricoh

Ricoh Aficio SG 3110DN User manual

Ricoh

Ricoh RT5120 Quick start guide

Ricoh

Ricoh PB1120 Quick start guide

Ricoh

Ricoh GR III User manual

Ricoh

Ricoh aficio 1013 User manual

Ricoh

Ricoh DU5040 Quick start guide

Ricoh

Ricoh D392 Installation guide

Ricoh

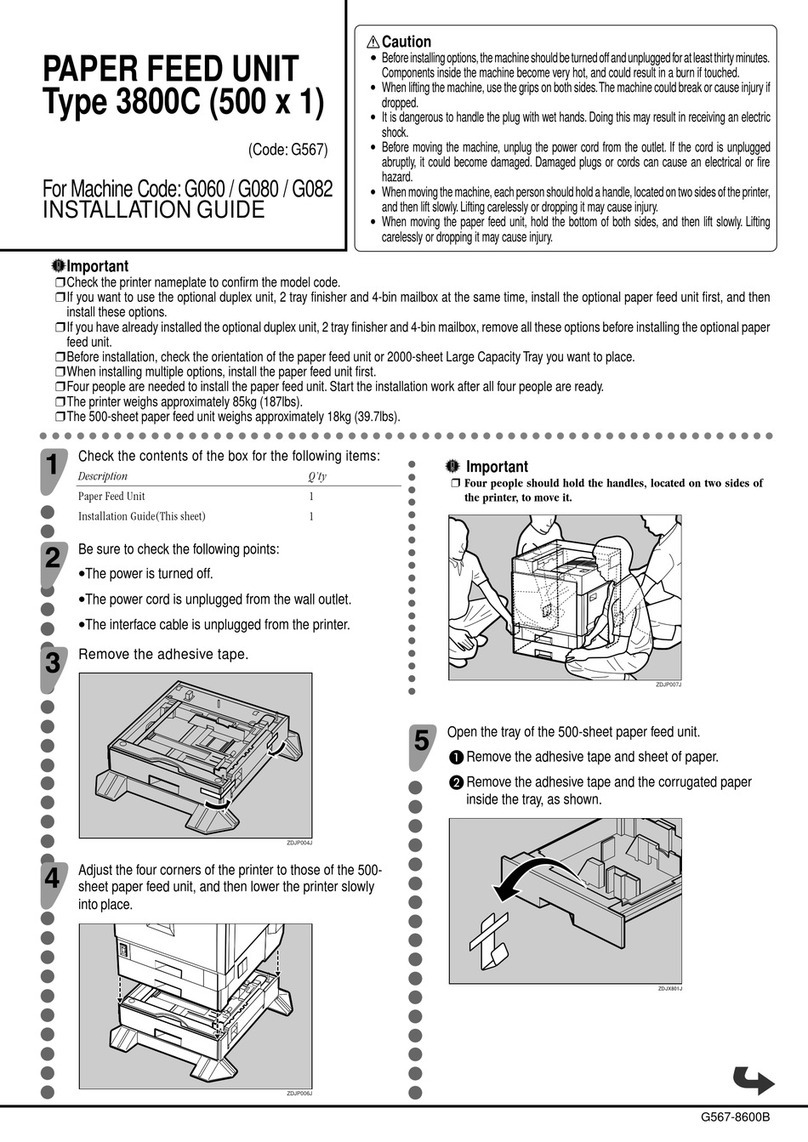

Ricoh 3800C Series User manual

Ricoh

Ricoh Aficio AP4510 Parts list manual

Ricoh

Ricoh Priport DX 4640PD User manual

Ricoh

Ricoh BN1040 Quick start guide

Ricoh

Ricoh Paper Bank PS470 User manual

Ricoh

Ricoh MP CW2201sp User manual

Ricoh

Ricoh AP600N User manual

Ricoh

Ricoh SP C220 Operating manual

Ricoh

Ricoh 3800E Operating manual

Ricoh

Ricoh TR5050 Quick start guide

Ricoh

Ricoh Aficio 3030 User manual

Ricoh

Ricoh BY5020 Quick start guide