Rev. 2.00

■ Table of Contents

1. Specifications ............................................................................................................14

2. Disassembly diagram................................................................................................16

3. Part names .................................................................................................................17

4. Connector pin arrangement......................................................................................18

4-1 Main FPC cable (50pin)..........................................................................................18

4-2 FPC aux cable (BMS option)..................................................................................19

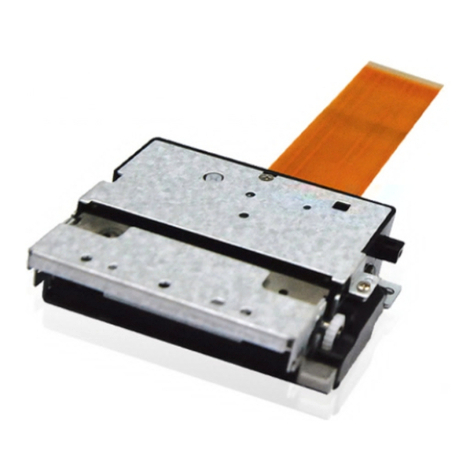

5. Thermal Printer Head.................................................................................................20

5-1 Specifications..........................................................................................................20

5-2 Block Diagram of the Head.....................................................................................20

5-3 Printing position of transferred data........................................................................21

5-4 Dimensions of thermal device.................................................................................22

5-5 Electrical Characteristics of the Thermal Head.......................................................23

5-6 Thermal Head Drive Timing Diagram .....................................................................24

5-7 Maximum Condition................................................................................................25

5-8 Head Supply Voltage..............................................................................................25

5-9 Peak current...........................................................................................................25

5-10 Pulse Width Control of the Head...........................................................................26

5-10-1 Voltage pulse width...................................................................................26

5-10-2 Calibration of the pulse width when temperature changes .......................26

5-10-3 Example calculation of head operating pulse width(SLT=0.5ms/line).......26

5-10-4 Thermistor specifications..........................................................................27

5-10-5 Detection of abnormal temperature of thermal head ................................28

6. Step Motor (Paper Feed) ...........................................................................................29

6-1 Specifications..........................................................................................................29

6-2 Example drive circuits.............................................................................................29

6-3 Drive sequence (Motor rotates in counterclockwise direction)................................31

6-4 Motor Timing Diagram............................................................................................32

6-5 Drive Frequency Acceleration (Acceleration Control).............................................32

7. Sensor.........................................................................................................................34

7-1 Paper Detection Sensor and Black Mark Detection Sensor....................................34

7-1-1 Absolute maximum rating ...........................................................................34

7-1-2 Electrical Characteristics ............................................................................34

7-1-3 Paper Detection Sensor Sample External Circuits .....................................35

7-1-4 Black Mark Detection Sensor Sample External Circuits .............................36

7-2 Platen Roller Block Detection Switch......................................................................37

7-2-1 Sample external circuits..............................................................................37

7-3 Auto Cutter .............................................................................................................38

7-4 Step Motor (Auto Cutter).........................................................................................40

7-4-1 Auto Cutter Drive Circuits ...........................................................................40

7-4-2 Auto Cutter Sensor(Home Sensor).............................................................41

7-4-3 Auto Cutter Flow Chart ...............................................................................43

7-4-4 Acceleration Step........................................................................................44

7-4-5 Auto Cutter Timing Diagram........................................................................45