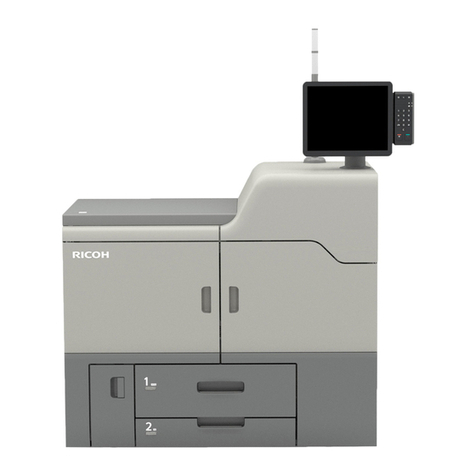

1.5 Outline of Mechanism

1.5.1 Main unit layout diagram

Exposure unit

A xenon lamp is used for flash

exposure. A stepper motor

moves mirrors and lens for the

desired magnification:

0.64 to 1.42

RDH

The air knife separates the leading edges of

the originals. The lowest original is held

against the transport belts by the suction of

the vacuum fan and fed by the belts. Even

in one-to-one copying, this high-speed ADF

can meet 101 CPM. Automatic duplex

copying is also available.

Fusing unit

Heat and pressure roller

system is used with silicon oil.

Paper feed tray

The upper tray stacks

up to 500 sheets. The

middle and lower

trays stack up to

1,000 sheets. FRR

system is used as the

paper feed

mechanism.

Duplex unit

The air knife separates the leading edge of

the copies. The lowest copy is held against

the transport belts by the suction of the

vacuum fan and fed by the belts.

Horizontal transport unit

Transports paper from the

LCT.

Transfer and

separation unit

A high voltage

negative corona

transfers positively

charged toner to

paper. A high voltage

ac corona breaks the

attraction between the

paper and OPC.

Cleaning unit

Magnetic brush system for

cleaning. Scavenging

roller collects toner from

the magnetic brush. (--) dc

bias voltage is applied to

the cleaning roller and

scavenging roller. (+) dc is

applied to the PCC to

increase cleaning

efficiency.

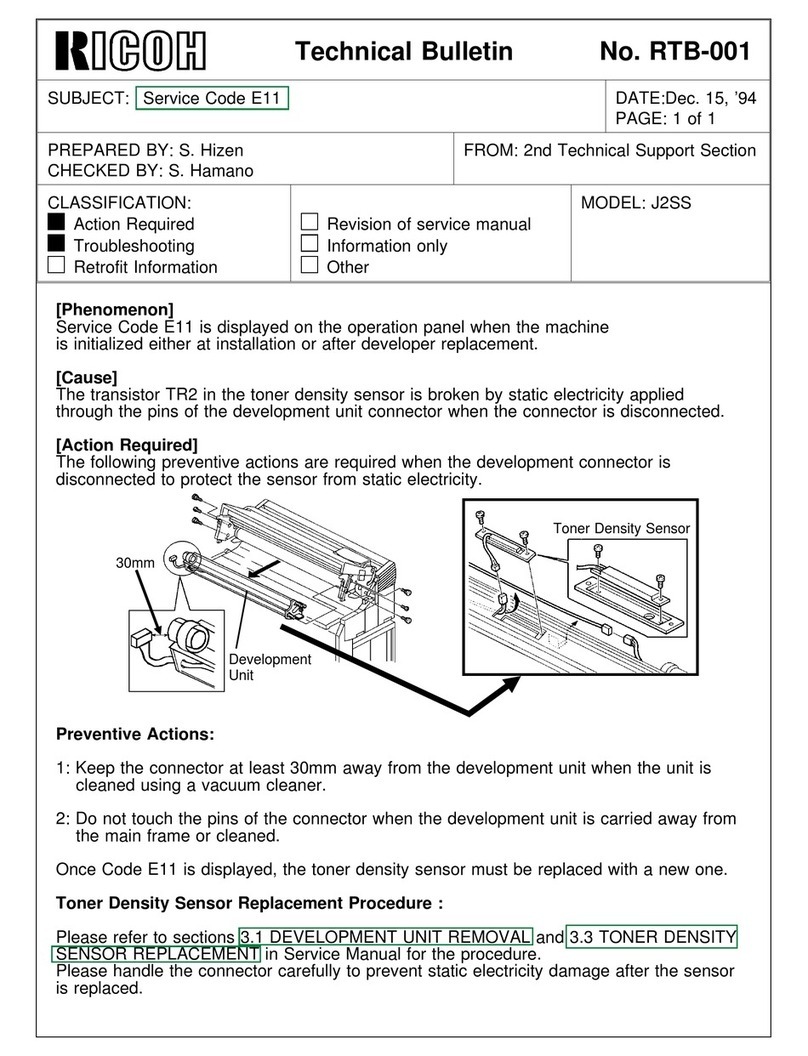

Development unit

Employs a magnetic brush

system using 3 magnetic rollers.

For toner density control, toner

density and ID sensors are

used. Toner is replenished from

a cartridge.

Photoconductor

An OPC belt is used as the

photoconductor. Its image

producing area is equally divided

into 5 A4/B5 segments, 4 B4

segments, or 3 A3 segments,

according to the copy paper size.

OPC cleaning brush

Removes filming material from

the OPC surface and refreshes

OPC surface.

Eraser unit

Erase system

employs LEDs.

Charge corona unit

Scorotron system is employed

to give a uniform and constant

electric charge on the OPC.

(--) dc high voltage is applied

to a tungsten wire, and the

OPC is charged negatively by

corona discharge.

1 July 1994 Outline of Mechanism

1-7