STILL HAVE QUESTIONS?

Tech line hours

0RQGD\)ULGD\$P30(67

NOTE:

Please read thorough this manual completely before installing the air

spring kit on your vehicle.

STEP 1 — PREPARE THE VEHICLE

With the vehicle on a solid, level surface chock the front wheels.

Remove the negative battery cable. Your vehicle is equipped with

rubber jounce bumpers. The jounce bumpers are bolted to the frame

above the axle. Remove the jounce bumpers from the vehicle.

STEP 2 — PRE-ASSEMBLE THE KIT

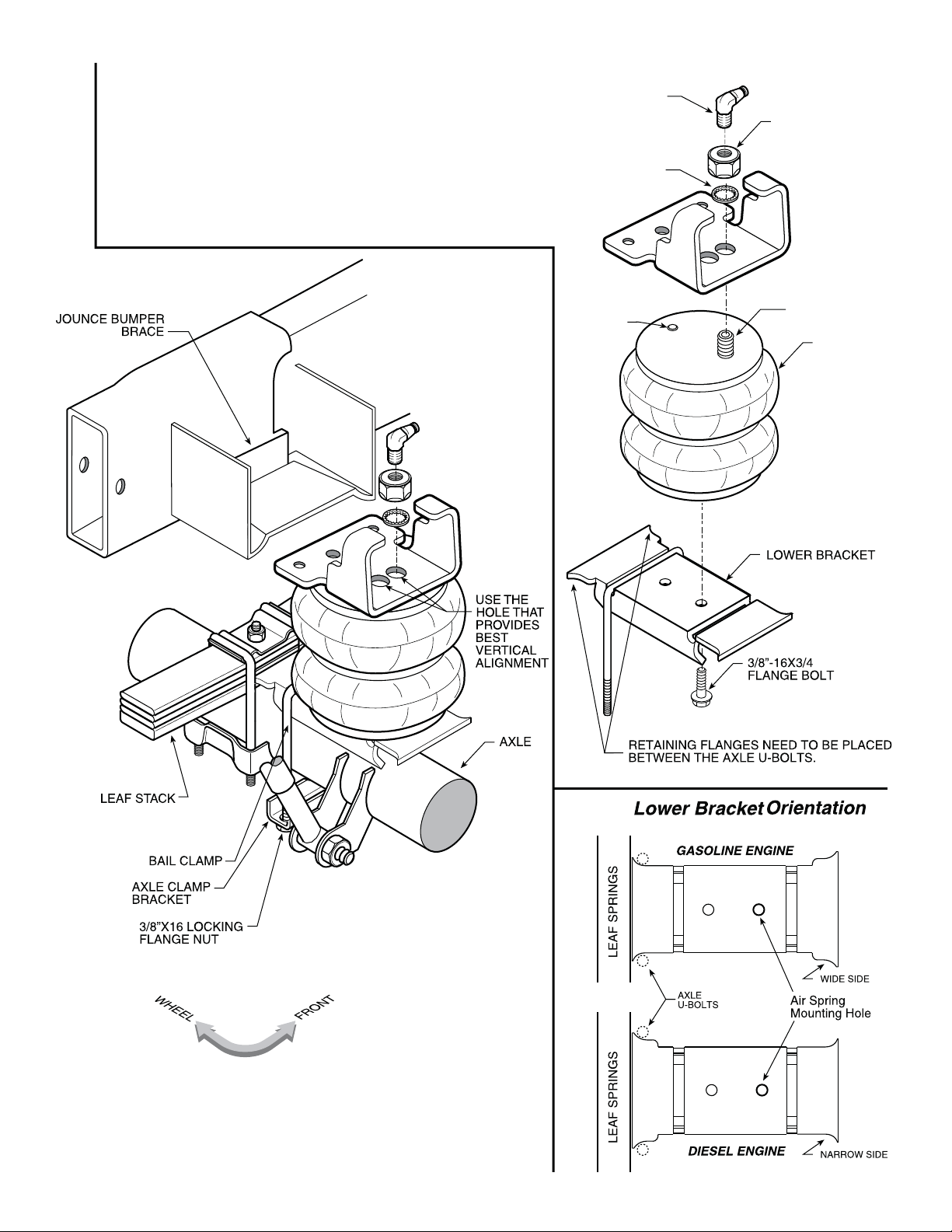

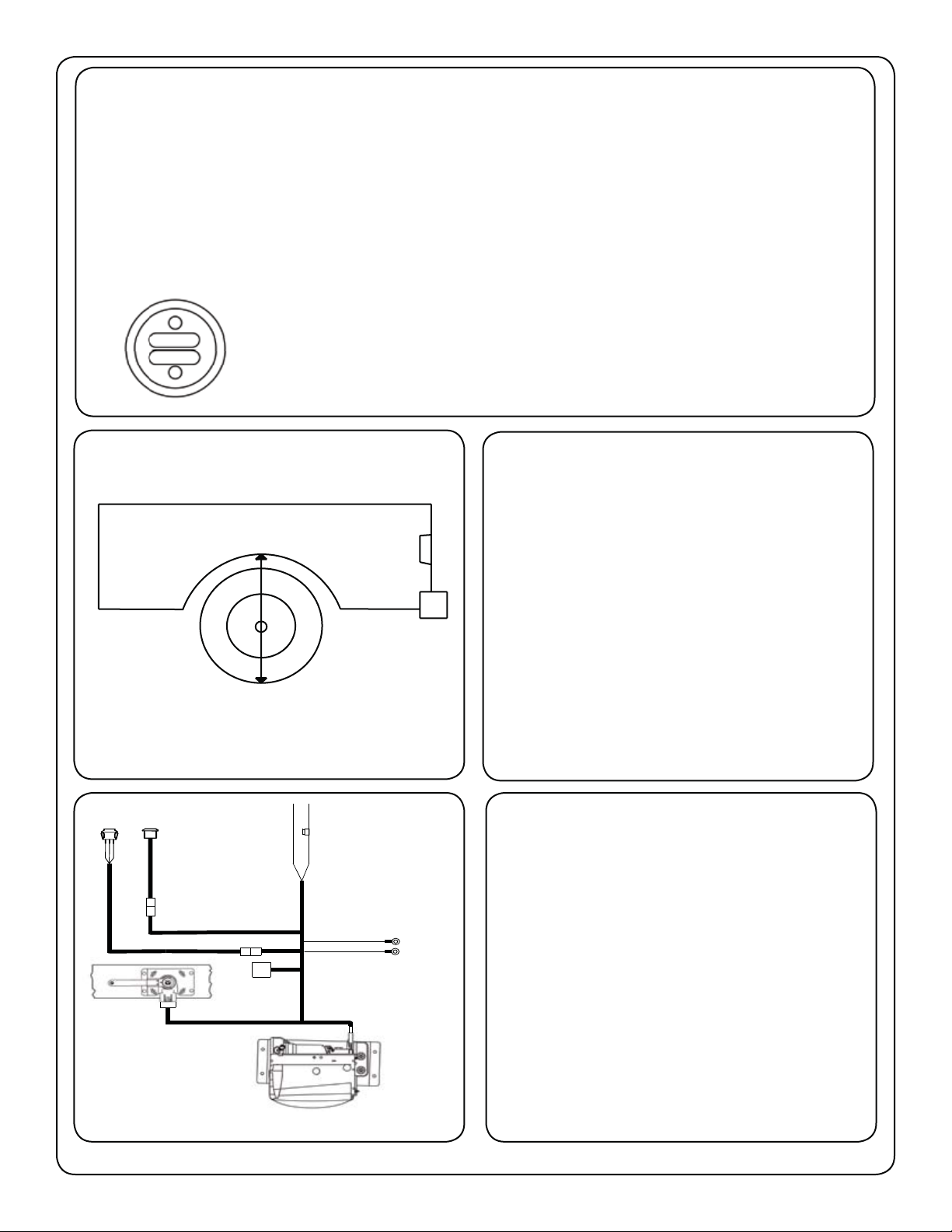

Select a lower bracket from your kit and determine which side of the

Figure

“A”. NOTE: The smaller side is for the gasoline engine axle and

the larger side is for Diesel engine axle.Select one air spring, bail

clamp and lower bracket from your kit. Place the bail clamp in the

correct position in the slot of the lower bracket for your vehicle. Install

the air spring to the lower bracket using the hole for your vehicle with

Please

see the lower right section of Figure “A”. The bolt will be tightened

up in STEP 5.

STEP 3 — INSTALLING THE UPPER BRACKET TO THE

VEHICLE

Select an upper bracket from your kit. Install the upper bracket to the

Figure “A”.

STEP 4—INSTALLING THE ASSEMBLY TO THE VEHICLE

Position the lower bracket and air spring assembly from STEP 2 on

the axle as shown in Figure “A”. Put the large threaded stud though

the large hole on the upper bracket and the locating pin of the air

spring in the small hole on the upper bracket as shown in Figure “A”.

Make sure the aliment pin is in the locating hole before fasting

air spring to the upper bracket. Fasten the air spring to the upper

bracket using ¾"-16 hex head nut and ¾" star washer. Fasten the

lower bracket to the axle housing using the bail clamp and the axle

securely to engage the orange thread sealant.

STEP 5— INSTALLATION OF THE PASSENGER’S SIDE

ASSEMBLY

Before following STEPS 1-4 with reverse orientations for assembly

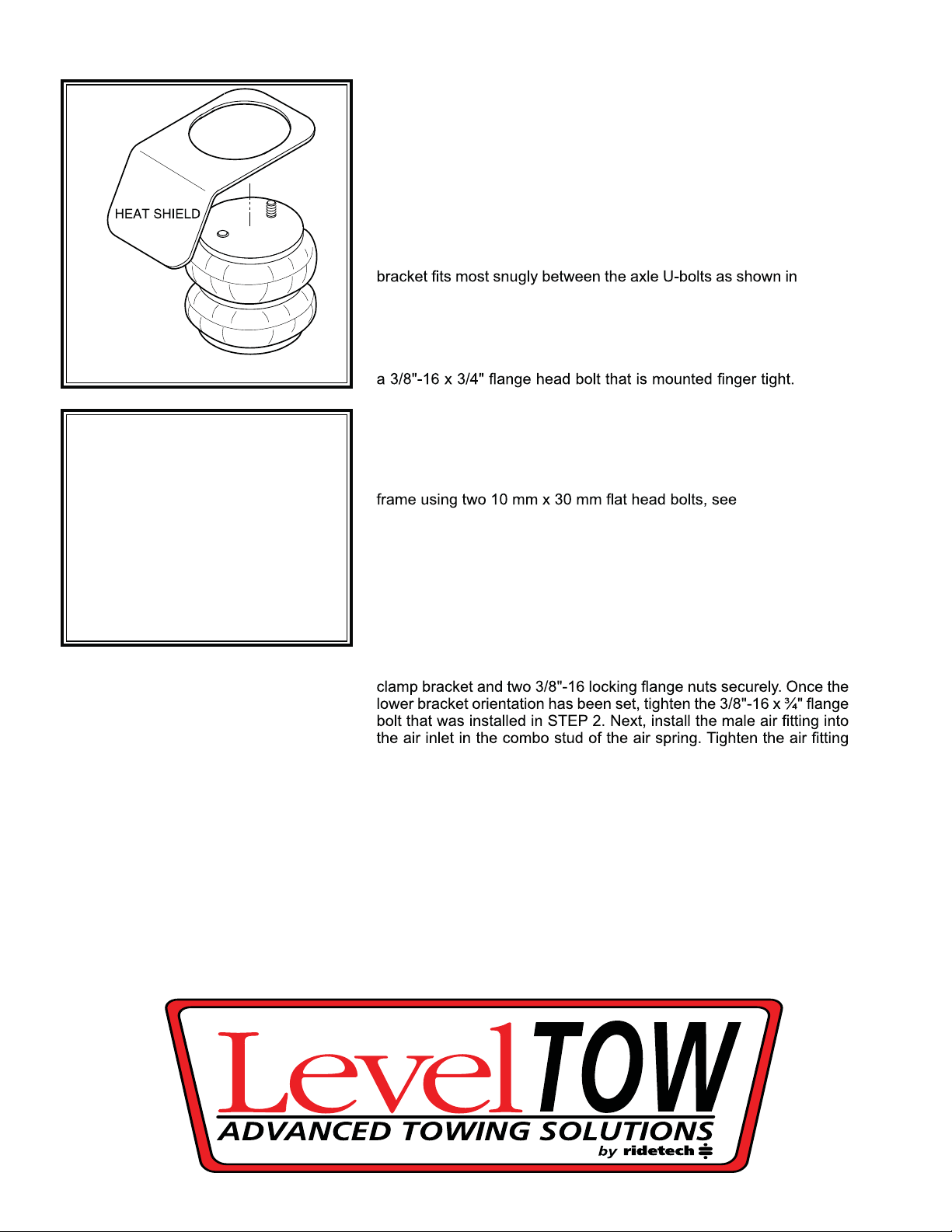

and installation of the passenger’s assembly, a heat shield will need

to be mounted between the upper bracket assembly and the top plate

of the air spring, see Figure “B”. Position the heat shield directly

between the closest heat source and the air spring. Ensure that the

heat shield will not interfere with normal operation of the air spring

or the vehicle’s suspension. Do not position the heat shield directly

above the axle, as it may contact the axle on full suspension travel.

FIGURE “B” (Step 5)

Important:

In order for the air spring

to function properly, there

must be a minimum of 1/2"

of clearance around the air

spring.