17

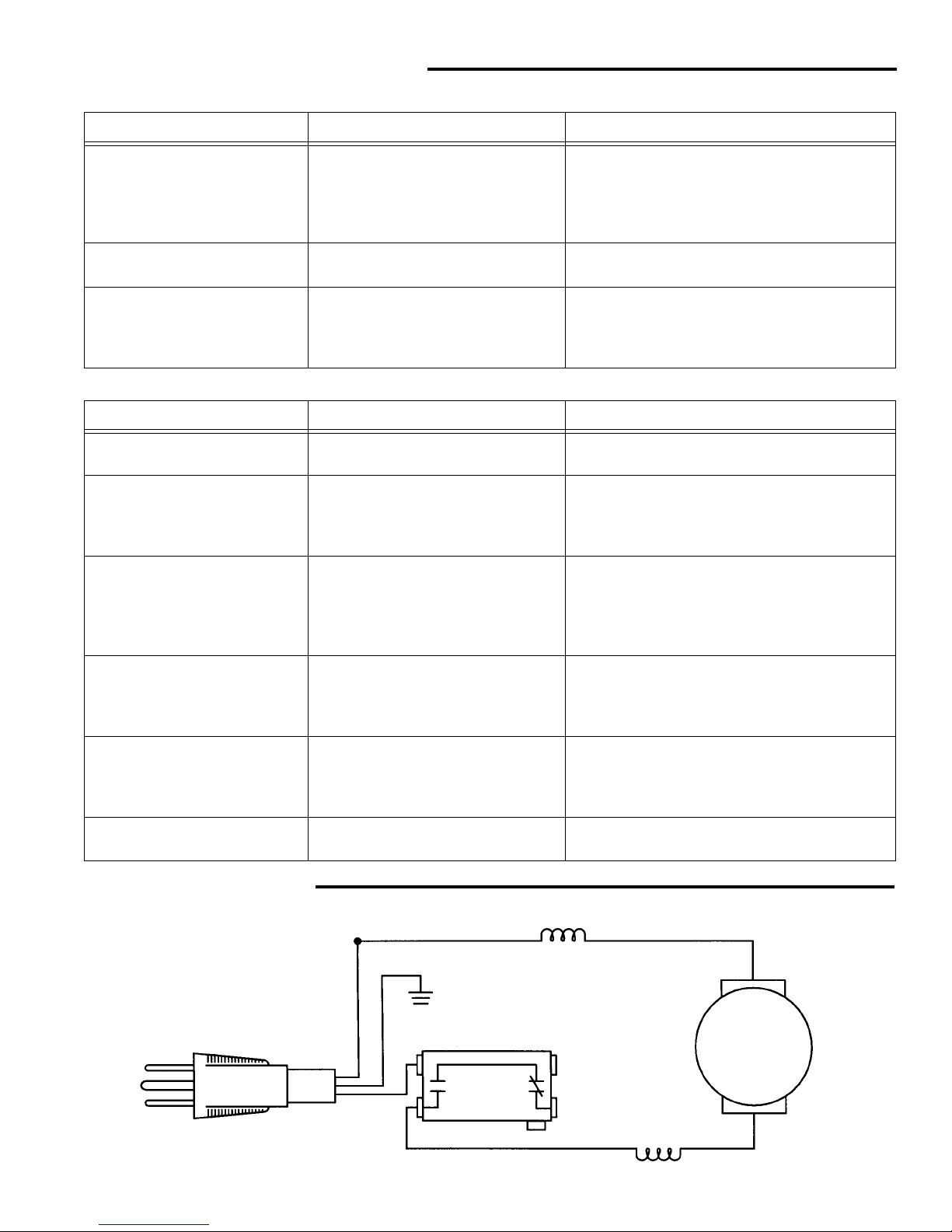

Troubleshooting Guide

Motor

General

Wiring Diagram

Problem Probable Cause Suggested Corrective Action

Motor does not start. 1. Fuse.

2. Brushes worn.

3. Other.

4. Low voltage

- 15 amp time delay fuse, or circuit breaker.

- See “Maintenance” section.

- Get authorized RIDGID service.

- Check power supply for proper voltage and

correct as needed

Brush sparking when switch

released. 1. Normal automatic brake working

properly. - None

Motor stalls easily 1. Low voltage

2. Excessive wheel pressure when

cutting

- Check power supply for proper voltage and

correct as needed

- Pull wheel through work at a slower pace

Problem Probable Cause Suggested Corrective Action

Cut-off wheel hits base or

work surface. 1. Misalignment

2. Downstop out of adjustment - Get Authorized Service.

- See “Alignment” section

Cut is not square. 1. Defective wheel

2. Work not positioned properly

3. Excessive wheel pressure

- Replace immediately

- Position work properly

- Lessen wheel pressure

(Don’t push down on handle so hard)

Power head won’t fully rise or

lower guard won’t fully close 1. Lubrication needed

2. Part failure

3. Pivot spring or guard spring not

replaced properly after service

4. Dirt sticking to stops

- See “Lubrication” section.

- Get Authorized Service.

- Get Authorized Service.

- Inspect/clean stops.

Cut-off wheel binds, jams,

burns workpiece.

Rough cuts

1. Improper operation

2. Dull cut-off wheel

3. Improper cut-off wheel

- See “Basic Operation” section.

- Replace wheel.

- Replace with 14” diameter wheel designed

for the material being cut.

Tool vibrates or shakes 1. Wheel not round

2. Wheel damaged

3. Wheel loose

4. Other

- Replace wheel.

- Replace wheel.

- Tighten arbor screw.

- Get Authorized Service.

Power head hard to pull/push

down 1. Lube needed See - “Lubrication” section.

Black

Switch

Black

N.C

.

N.O.

Black

Armature

Brush

Brush

White

Ground