1

CONTENTS

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

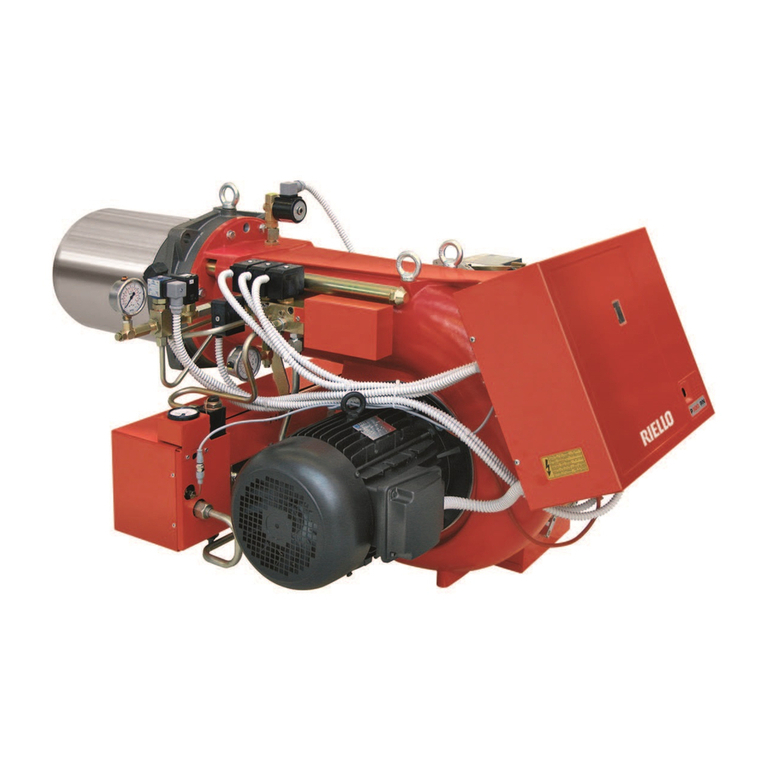

Burner description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Packaging - Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Max. dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Standard equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Firing rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Test boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Boiler plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Blast tube length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Securing the burner to the boiler . . . . . . . . . . . . . . . . . . . . . . . . . 5

Choice of nozzles for 1st and 2nd stage . . . . . . . . . . . . . . . . . . . 6

Nozzle assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Combustion head adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pump priming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Burner calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Burner operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Final checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Burner start-up cycle diagnostics. . . . . . . . . . . . . . . . . . . . . . . . 15

Resetting the control box and using diagnostics . . . . . . . . . . . . 15

Faults - Possible causes - Solutions . . . . . . . . . . . . . . . . . . . . . 16

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

N.B.

Figures mentioned in the text are identified as follows:

1)(A) =Part 1 of figure A, same page as text;

1)(A)p.3 =Part 1 of figure A, page number 3.

INFORMATION ABOUT THE INSTRUCTION

MANUAL

INTRODUCTION

The instruction manual supplied with the burner:

- is an integral and essential part of the product and must not be

separated from it; it must therefore be kept carefully for any nec-

essary consultation and must accompany the burner even if it is

transferred to another owner or user, or to another system. If the

manual is lost or damaged, another copy must be requested from

the Technical Assistance Service of the area;

- is designed for use by qualified personnel;

- offers important indications and instructions relating to the instal-

lation safety, start-up, use and maintenance of the burner.

DELIVERY OF THE SYSTEM AND THE INSTRUCTION

MANUAL

When the system is delivered, it is important that:

- The instruction manual is supplied to the user by the system

manufacturer, with the recommendation to keep it in the room

where the heat generator is to be installed.

- The instruction manual shows:

- the serial number of the burner;

- the address and telephone number of the nearest Assistance

Centre;

- The system supplier carefully informs the user about:

- the use of the system,

- any further tests that may be necessary before the system is

started up,

- maintenance and the need to have the system checked at

least once a year by the manufacturer or another specialised

technician.

To ensure a periodic check, recommends the draw-

ing up of a Maintenance Contract.

NOTE

In conformity with Efficiency Directive 92/42/EEC the application

of the burner on the boiler, adjustment and testing must be car-

ried out observing the instruction manual of the boiler, including

verification of the CO and CO2concentration in the flue gases,

their temperatures and the average temperature of the water in

the boiler.

GB

..................................................................................

..................................................................................

..................................................................................

..................................................................................