Rigol DM3068 Installation and operation manual

RIGOL

Performance Verification Guide

DM3068 Digital Multimeter

Dec. 2014

RIGOL Technologies, Inc.

RIGOL

DM3068 Performance Verification Guide

I

Guaranty and Declaration

Copyright

©2014 RIGOL Technologies, Inc. All Rights Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL Technologies, Inc.

Publication Number

PVC06100-1110

Notices

RIGOL products are covered by P.R.C. and foreign patents, issued and pending.

RIGOL reserves the right to modify or change parts of or all the specifications and pricing

policies at company’s sole decision.

Information in this publication replaces all previously corresponding material.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in connection with the

furnishing, use or performance of this manual as well as any information contained.

Any part of this document is forbidden to be copied, photocopied or rearranged without prior

written approval of RIGOL.

Product Certification

RIGOL guarantees this product conforms to the national and industrial standards in China as well as

the ISO9001:2008 standard and the ISO14001:2004 standard. Other international standard

conformance certification is in progress.

Contact Us

If you have any problem or requirement when using our products or this manual, please contact

RIGOL.

E-mail: service@rigol.com

Website: www.rigol.com

RIGOL

II DM3068 Performance Verification Guide

Safety Requirement

General Safety Summary

Please review the following safety precautions carefully before putting the instrument into operation

so as to avoid any personal injury or damage to the instrument and any product connected to it. To

prevent potential hazards, please use the instrument only specified by this manual.

Use Proper Power Cord.

Only the power cord designed for the instrument and authorized for use within the local country

could be used.

Ground the Instrument.

The instrument is grounded through the Protective Earth lead of the power cord. To avoid electric

shock, it is essential to connect the earth terminal of the power cord to the Protective Earth terminal

before connecting any inputs or outputs.

Connect the Probe Correctly.

If a probe is used, do not connect the ground lead to high voltage since it has isobaric electric

potential as the ground.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings and markers on the instrument and check your

manual for more information about ratings before connecting the instrument.

Use Proper Overvoltage Protection.

Make sure that no overvoltage (such as that caused by a thunderstorm) can reach the product, or

else the operator might be exposed to the danger of electrical shock.

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

Do Not Insert Anything Into the Holes of Fan.

Do not insert anything into the holes of the fan to avoid damaging the instrument.

Use Proper Fuse.

Please use the specified fuses.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered.

RIGOL

DM3068 Performance Verification Guide

III

Do Not Operate With Suspected Failures.

If you suspect damage occurs to the instrument, have it inspected by RIGOL authorized personnel

before further operations. Any maintenance, adjustment or replacement especially to circuits or

accessories must be performed by RIGOL authorized personnel.

Keep Well Ventilation.

Inadequate ventilation may cause an increase of instrument temperature which would cause damage

to the instrument. So please keep the instrument well ventilated and inspect the intake and fan

regularly.

Do Not Operate in Wet Conditions.

In order to avoid short circuiting to the interior of the device or electric shock, please do not operate

the instrument in a humid environment.

Do Not Operate in an Explosive Atmosphere.

In order to avoid damage to the device or personal injuries, it is important to operate the device away

from an explosive atmosphere.

Keep Product Surfaces Clean and Dry.

To avoid the influence of dust and/or moisture in the air, please keep the surface of the device clean

and dry.

Electrostatic Prevention.

Operate the instrument in an electrostatic discharge protective environment to avoid damage

induced by static discharges. Always ground both the internal and external conductors of cables to

release static before making connections.

Proper Use of Battery.

If a battery is supplied, it must not be exposed to high temperature or in contact with fire. Keep it out

of the reach of children. Improper change of battery (note: lithium battery) may cause explosion. Use

RIGOL specified battery only.

Handling Safety.

Please handle with care during transportation to avoid damage to buttons, knob interfaces and other

parts on the panels.

RIGOL

IV DM3068 Performance Verification Guide

The disturbance tests of all models conform to the P/F values of A based on the standard

of EN 61326: 1997+A1+A2+A3 instead of P/F values of B.

Input Terminal Protection Limit

The protection limits are defined for the input terminals.

1.Main input (HI and LO) terminals

The HI and LO input terminals are used for voltage, resistance, capacitance, continuity,

frequency and diode measurements. Two protection limits are defined for these terminals.

1) HI-LO protection limit: 1000VDC or 750VAC; this is also the maximum measurable voltage.

The limit can be expressed as up to 1000Vpk.

2) LO-ground protection limit: the LO input terminal can safely float to 500Vpk at most relative

to the ground.

Since the protection limit of the HI input terminal is up to 1000Vpk relative to the ground, the

sum of the “floating” voltage and measured voltage cannot exceed 1000Vpk.

2.Sampling (HI Sense and LO Sense/200mA) terminals

The HI Sense and LO Sense/200mA terminals are used for 4-wire resistance measurement.

Two protection limits are defined for these terminals.

1) HI Sense-LO Sense/200mA protection limit: 200Vpk.

2) LO Sense/200mA-LO protection limits: 0.5Vpk. The current input fuse on the rear panel

provides up to 500mA protection limit for the current passing through the LO

Sense/200mA terminal.

3.Current input (10A and Sense/200mA) terminals

The 10A and LO terminals are used for the current measurements of 2A and 10A ranges

respectively. The internal fuse of the multimeter provides 10A protection limit for the current

passing through the 10A terminal. The LO Sense/200mA and LO terminals are used for

current measurements ranging from 200uA to 200mA. The current input fuse on the rear panel

provides up to 500mA protection limit for the current passing through the LO Sense/200mA

terminal.

NOTE:

In order to prevent the fuse from blowing out and protect the multimeter, please

use the current input terminals according to the following requirements.

1) Do not connect the 10A and LO Sense/200mA input terminals to the current

measurement circuit at the same time.

2) Only use the 10A and LO terminals for measurements when the AC+DC RMS value of the

current under measurement is within 200mA and 10A.

3) When making current measurement, select a proper current input terminal according to the

estimated current magnitude before connecting the multimeter to AC power supply.

4) The current input into the 10A terminal cannot exceed 13.5A; otherwise, the internal fuse

of the multimeter will be burned out. The current input into the LO Sense/200mA

terminal cannot exceed 650mA; otherwise, the current input fuse on the rear panel may be

burned out.

RIGOL

DM3068 Performance Verification Guide

V

IEC II Overvoltage Protection

In order to avoid the danger of electric shock, DM3068 provides overvoltage protection for

line-voltage mains connections meeting both of the following conditions.

1.The HI and LO input terminals are connected to the mains under Measurement Category II

conditions defined below.

2.The mains are limited to a maximum line voltage of 300VAC.

WARNING: IEC II includes electrical devices connected to mains through an outlet from the branch

circuit. Such devices include most small appliances, test equipments and other devices inserted into a

branch socket.

DM3068 may be used to make measurements with the HI and LO inputs connected to mains in such

devices (up to 300VAC), or to the branch socket. However, the HI and LO inputs of DM3068 cannot be

connected to mains of permanently installed electrical devices such as a main circuit-breaker panel,

sub-panel disconnected box or wired motors. Voltages beyond the protection limit of DM3068 may

occur on such devices and circuits.

NOTE: Voltages above 300VAC may be measured only in circuits that are isolated from mains.

However, a transient overvoltage is also present in such circuits. DM3068 was designed to safely

withstand occasional transient overvoltage up to 2500Vpk. Do not use this device to measure circuits

whose transient overvoltage may exceed this level.

RIGOL

VI DM3068 Performance Verification Guide

Safety Terms and Symbols

Terms Used in this Manual. These terms may appear in this manual:

WARNING

Warning statements indicate the conditions or practices that could result in injury or loss

of life.

CAUTION

Caution statements indicate the conditions or practices that could result in damage to this

product or other property.

Terms Used on the Product. These terms may appear on the product:

DANGER It calls attention to an operation, if not correctly performed, could result in injury or

hazard immediately.

WARNING

It calls attention to an operation, if not correctly performed, could result in potential

injury or hazard.

CAUTION

It calls attention to an operation, if not correctly performed, could result in damage to

the product or other devices connected to the product.

Symbols Used on the Product. These symbols may appear on the product:

Hazardous

Voltage

Safety

Warning

Protective

Earth

Terminal

Chassis

Ground

Test

Ground

RIGOL

DM3068 Performance Verification Guide

VII

Allgemeine Sicherheits Informationen

Überprüfen Sie diefolgenden Sicherheitshinweise sorgfältigumPersonenschädenoderSchäden am

Gerätundan damit verbundenen weiteren Gerätenzu vermeiden. Zur Vermeidung vonGefahren,

nutzen Sie bitte das Gerät nur so, wiein diesem Handbuchangegeben.

Um Feuer oder Verletzungen zu vermeiden, verwenden Sie ein ordnungsgemäßes

Netzkabel.

Verwenden Sie für dieses Gerät nur das für ihr Land zugelassene und genehmigte Netzkabel.

Erden des Gerätes.

Das Gerät ist durch den Schutzleiter im Netzkabel geerdet. Um Gefahren durch elektrischen Schlag zu

vermeiden, ist es unerlässlich, die Erdung durchzuführen. Erst dann dürfen weitere Ein- oder

Ausgänge verbunden werden.

Anschluss einesTastkopfes.

Die Erdungsklemmen der Sonden sindauf dem gleichen Spannungspegel des Instruments geerdet.

SchließenSie die Erdungsklemmen an keine hohe Spannung an.

Beachten Sie alle Anschlüsse.

Zur Vermeidung von Feuer oder Stromschlag, beachten Sie alle Bemerkungen und Markierungen auf

dem Instrument. Befolgen Sie die Bedienungsanleitung für weitere Informationen, bevor Sie weitere

Anschlüsse an das Instrument legen.

Verwenden Sie einen geeigneten Überspannungsschutz.

Stellen Sie sicher, daß keinerlei Überspannung (wie z.B. durch Gewitter verursacht) das Gerät

erreichen kann. Andernfallsbestehtfür den Anwender die GefahreinesStromschlages.

Nicht ohne Abdeckung einschalten.

Betreiben Sie das Gerät nicht mit entfernten Gehäuse-Abdeckungen.

Betreiben Sie das Gerät nicht geöffnet.

Der Betrieb mit offenen oder entfernten Gehäuseteilen ist nicht zulässig. Nichts in entsprechende

Öffnungen stecken (Lüfter z.B.)

Passende Sicherung verwenden.

Setzen Sie nur die spezifikationsgemäßen Sicherungen ein.

Vermeiden Sie ungeschützte Verbindungen.

Berühren Sie keine unisolierten Verbindungen oder Baugruppen, während das Gerät in Betrieb ist.

Betreiben Sie das Gerät nicht im Fehlerfall.

Wenn Sie am Gerät einen Defekt vermuten, sorgen Sie dafür, bevor Sie das Gerät wieder betreiben,

RIGOL

VIII DM3068 Performance Verification Guide

dass eine Untersuchung durch RIGOL autorisiertem Personal durchgeführt wird. Jedwede Wartung,

Einstellarbeiten oder Austausch von Teilen am Gerät, sowie am Zubehör dürfen nur von RIGOL

autorisiertem Personal durchgeführt werden.

Belüftung sicherstellen.

Unzureichende Belüftung kann zu Temperaturanstiegen und somit zu thermischen Schäden am Gerät

führen. Stellen Sie deswegen die Belüftung sicher und kontrollieren regelmäßig Lüfter und

Belüftungsöffnungen.

Nicht in feuchter Umgebung betreiben.

Zur Vermeidung von Kurzschluß im Geräteinneren und Stromschlag betreiben Sie das Gerät bitte

niemals in feuchter Umgebung.

Nicht in explosiver Atmosphäre betreiben.

Zur Vermeidung von Personen- und Sachschäden ist es unumgänglich, das Gerät ausschließlich

fernab jedweder explosiven Atmosphäre zu betreiben.

Geräteoberflächen sauber und trocken halten.

Um den Einfluß von Staub und Feuchtigkeit aus der Luft auszuschließen, halten Sie bitte die

Geräteoberflächen sauber und trocken.

Schutz gegen elektrostatische Entladung (ESD).

Sorgen Sie für eine elektrostatisch geschützte Umgebung, um somit Schäden und

Funktionsstörungen durch ESD zu vermeiden. Erden Sie vor dem Anschluß immer Innen- und

Außenleiter der Verbindungsleitung, um statische Aufladung zu entladen.

Die richtige Verwendung desAkku.

Wenneine Batterieverwendet wird, vermeiden Sie hohe Temperaturen bzw. Feuer ausgesetzt werden.

Bewahren Sie es außerhalbder Reichweitevon Kindern auf. UnsachgemäßeÄnderung derBatterie

(Anmerkung: Lithium-Batterie) kann zu einer Explosion führen. VerwendenSie nur von RIGOL

angegebenenAkkus.

Sicherer Transport.

Transportieren Sie das Gerät sorgfältig (Verpackung!), um Schäden an Bedienelementen,

Anschlüssen und anderen Teilen zu vermeiden.

RIGOL

DM3068 Performance Verification Guide

IX

Sicherheits Begriffe und Symbole

Begriffe in diesem Guide. Diese Begriffe können in diesem Handbuch auftauchen:

WARNING

Die Kennzeichnung WARNING beschreibt Gefahrenquellen die leibliche Schäden oder den

Tod von Personen zur Folge haben können.

CAUTION

Die Kennzeichnung Caution (Vorsicht) beschreibt Gefahrenquellen die Schäden am Gerät

hervorrufen können.

Begriffe auf dem Produkt. Diese Bedingungen können auf dem Produkt erscheinen:

DANGER weist auf eine Verletzung oder Gefährdung hin, die sofort geschehen kann.

WARNING weist auf eine Verletzung oder Gefährdung hin, die möglicherweise nicht sofort

geschehen.

CAUTION weist auf eine Verletzung oder Gefährdung hin und bedeutet, dass eine mögliche

Beschädigung des Instruments oder anderer Gegenstände auftreten kann.

Symbole auf dem Produkt. Diese Symbole können auf dem Produkt erscheinen:

Gefährliche

Spannung

Sicherheits-

Hinweis Schutz-erde Gehäusemasse Erde

RIGOL

X DM3068 Performance Verification Guide

Document Overview

This manual guides users to correctly test the performance specifications of RIGOL DM3068 digital

multimeter. For the operation method of the instrument, please refer to the corresponding User’s

Guide.

Main contents in this manual:

Chapter 1 Test Overview

This chapter introduces the preparations of the performance verification test.

Chapter 2 Performance Verification Test

This chapter introduces the routine test methods of DM3068 performance verification test.

Appendix Test Record Form

In the appendix, a test record form is provided for recording the test results so as to determine

whether each performance specification fulfills the requirement.

Contents RIGOL

DM3068 Performance Verification Guide

XI

Contents

Guaranty and Declaration................................................................................................ I

Safety Requirement........................................................................................................II

General Safety Summary...................................................................................................II

Safety Terms and Symbols ............................................................................................... VI

Allgemeine Sicherheits Informationen............................................................................... VII

Sicherheits Begriffe und Symbole.......................................................................................IX

Document Overview.........................................................................................................X

Chapter 1 Test Overview ........................................................................................... 1-1

Test Type.......................................................................................................................1-1

Self-Test..................................................................................................................1-1

Quick Test...............................................................................................................1-2

Routine Test............................................................................................................1-3

Test Equipments.............................................................................................................1-3

Test Conditions ..............................................................................................................1-4

Input Connections..........................................................................................................1-5

Test Result Record..........................................................................................................1-5

Specifications.................................................................................................................1-5

Chapter 2 Performance Verification Test................................................................... 2-1

Zero Offset Test .............................................................................................................2-1

Gain Test .......................................................................................................................2-2

Appendix Test Record Form.............................................................................................1

Zero Offset .......................................................................................................................1

DC Gain............................................................................................................................2

AC Voltage Gain................................................................................................................3

AC Current Gain................................................................................................................4

Frequency Gain.................................................................................................................5

Capacitance Gain...............................................................................................................5

Chapter 1 Test Overview RIGOL

DM3068 Performance Verification Guide

1-1

Chapter 1 Test Overview

Test Type

The performance tests are used to check the measurement performance of the multimeter. DM3068

supports self-test, quick test and routine test.

Self-Test

Self-test is a series of internal calibration tests which can be used to reliably determine the usability of

the instrument. The self-test method is as follows.

Step 1: Turn on the multimeter.

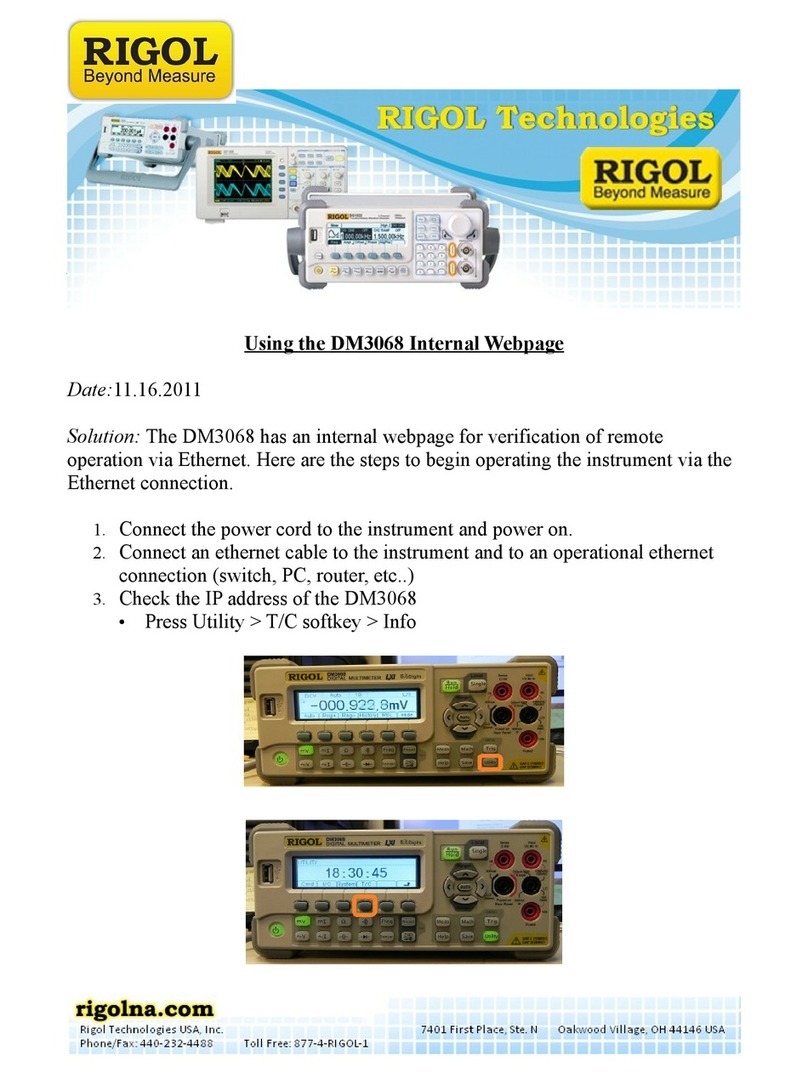

Step 2: Press Utility T/C Slftst Run to start the self-test. When abnormal situation

occurs during the test, the beeper sounds. “PASS!” or “FAIL!” is displayed on the screen

when the self-test finishes. If the instrument passes the self-test, it will be assumed that

the hardware of the instrument is working normally (confidence level>90%).

In remote mode, you can use the *TST? command to start the self-test and query its

result. The query returns “0” (the instrument passes the self-test) or “1” (the self-test

fails). The whole self-test process lasts about 18 seconds and appropriate interface

timeout period may need to be configured.

Step 3: The error messages during the self-test are stored in the error queue and you can view

them through pressing Utility T/C Error (or sending the SYSTem:ERRor?

comamnd) after the self-test finishes.

The table below lists the errors which may occur during the self-test.

Table 1-1 List of possible errors

Error Code Error Message

601 ADC offset too noisy

602 ADC fullscale too noisy

603 ADC gain test failed

604 OHM Common Drive Test

605 DCV Common Drive Test

606 DCI Common Drive Test

607 DC 200V Zero Test

608 DC 1000V Zero Test

609 Input Leakage Test

610 Ohms 0.2uA and DC x1 Test

611 DCV Autozero Test

RIGOL Chapter 1 Test Overview

1-2 DM3068 Performance Verification Guide

612 DCI Autozero Test

613 Precharge Offset Test.

614 DC 20V Gain Test

615 AC 200mV Zero Test

616 DC 200V Gain Test

617 DC x10 Gain Test

618 DC 1000V Gain Test

619 Low Current Shunt Test

620 High Current Shunt Test

621 Ohms 2uA Current Source Test

622 Ohms 10uA Current Source Test

623 Ohms 100uA Current Source Test

624 Ohms 1mA Current Source Test

625 AC Gain Test

626 Frequency counter Test

627 Capacitance Function Test

628 FPGA Configuration failed

NOTE

Although the multimeter automatically cuts off the connection with the input signal while

performing self-test, the AC signals from the input terminal may still enter the multimeter and cause

the failure of the self-test. So please do not start the self-test until you have disconnected all the

input connections.

The multimeter that failed the self-test must be repaired and calibrated before it is put back into

use.

Quick Test

Quick test is an easy way to inspect the functions and specifications of the multimeter with higher

confidence level. It contains only a few test points and can evaluate the accuracy of the multimeter in

normal use; however, it cannot detect abnormal element failures.

The quick test procedures are as follows.

Step 1: Run the test.

Step 2:

Execute the test items marked with “Q” (the quick test items) in

“

Chapter 2

Performance Verification Tests”.

NOTE

The quick test is not applicable to the instruments with abnormalities in some certain functions. The

multimeter that fails to pass the quick test must be calibrated or repaired before it is put back into

use.

Chapter 1 Test Overview RIGOL

DM3068 Performance Verification Guide

1-3

Routine Test

It is recommended that you perform routine test when you obtain the multimeter for the first time

and please compare the routine test results with the values of 1 year "Allowable Error Range" in Table

2-1 to Table 2-6 in “Chapter 2 Performance Verification Tests”. After that, you can verify the

performance of the instrument at the end of each calibration interval. It is recommended that you

calibrate the instrument at the end of each calibration interval.

NOTE

The multimeter that passes the routine test must be tested again when the test time interval

expires. The multimeter that fails to pass the routine test must be calibrated or repaired before it is

put back into use.

Test Equipments

Table 1-2 lists the equipments recommended for the test. If you do not have such equipments, use

other equipments that fulfill the "Precision Requirements" in the table.

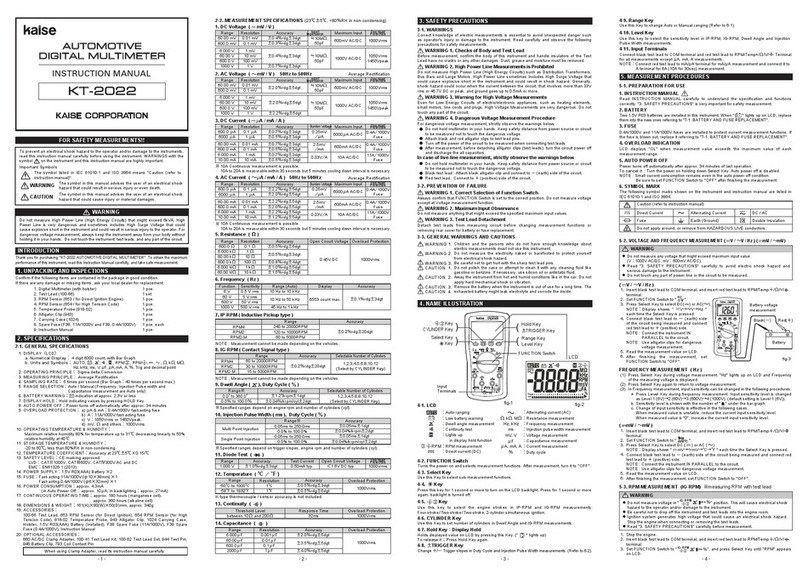

Table 1-2 Recommended equipments

Items Recommended Equipments Precision Requirements

Zero Offset Test None Pure copper 4-terminal short-circuiter

DC Voltage Fluke 5520A <1/5 of the 24 hour specification of the

instrument

DC Current Fluke 5520A <1/5 of the 24 hour specification of the

instrument

Resistance Fluke 5520A <1/5 of the 24 hour specification of the

instrument

AC Voltage Fluke 5520A <1/5 of the 24 hour specification of the

instrument

AC Current Fluke 5520A <1/5 of the 24 hour specification of the

instrument

Frequency Fluke 5520A <1/5 of the 24 hour specification of the

instrument

Capacitance Fluke 5520A <1/5 of the 24 hour specification of the

instrument

RIGOL Chapter 1 Test Overview

1-4 DM3068 Performance Verification Guide

Test Conditions

For the best performance, all the test processes should fulfill the following recommendations.

1. Always operate the instrument under a proper voltage.

2. Make sure the ambient temperature during the test is stable and within 18°C and 28°C.

3. The relative humidity should be lower than 80%.

4. Warm up the instrument for at least 90 minutes before testing the instrument.

5. Use a copper connector to reduce its thermoelectric potential effect.

6. Use Teflon shielded twisted pair (as short as possible) in order to reduce the effect of external

interference. In the process of capacitance test, a coaxial cable should be used to minimize the

external interference and noise.

7. Ground the shield of the twisted pair and the shield of the coaxial cable. Unless otherwise noted,

ground the LO terminal of the calibrator.

As DM3068 is a high-precision measuring instrument, special attention should be paid to the additional

error caused by the calibration source and calibration operations. In ideal situation, the accuracy of

the verification test and calibration standard source must be at least four times higher than that of the

test instrument.

When performing the gain calibration for DC voltage, DC current and resistance, the “0” output of the

calibrator must be correct. In order to reduce the errors caused by the connecting cables, adequate

warm-up (about 5 minutes) must be done before each reconnection of the cables or short-circuiter.

Chapter 1 Test Overview RIGOL

DM3068 Performance Verification Guide

1-5

Input Connections

To perform zero offset test, you must use a copper/copper alloy low thermoelectric potential

4-terminal short-circuiter. A coaxial cable whose shielding layer is connected to the LO terminal should

be used for capacitance test. For other function verification tests, Teflon shielded twisted pairs (as

short as possible) should be used to connect the multimeter and calibrator. The cables connecting the

HI and LO terminals as well as the HI-Sense and LO-Sense terminals should be twisted together

respectively. Besides, the shielding layers of the cables must be connected to the reference ground.

This kind of connections can reduce the effect of thermoelectric potential and external interference.

Figure 1-1 Input terminals

Test Result Record

Record and keep the test result of each test. In "Appendix Test Record Form" of this manual, a

test result record form which lists all the test items and their corresponding performance limits as

well as spaces for users to record the test results, is provided.

Tip:

It

is recommended that users photocopy the test record form before each test and record the test

results in the copy so that the form can be used repeatedly.

Specifications

The allowable error range of each test item, calculated based on the specification of DM3068, is

provided in chapter 2. For the technical specifications of DM3068, refer to

DM3068 User’s Guide

or

DM3068 Data Sheet

(can be downloaded from www.rigol.com).

HI-Sense

LO-Sense/200mA

HI

LO

10A

Other manuals for DM3068

5

Table of contents

Other Rigol Multimeter manuals

Rigol

Rigol DM3068 User manual

Rigol

Rigol DM3058 User manual

Rigol

Rigol DM3058E User manual

Rigol

Rigol DM3061 User manual

Rigol

Rigol DM3058 Use and care manual

Rigol

Rigol DM3061 User manual

Rigol

Rigol DM3058 Operating instructions

Rigol

Rigol DM3068 User manual

Rigol

Rigol DM3068-OB User manual

Rigol

Rigol DM3058 Operating instructions